Tin sulfide@niobium disulfide (SnS@NbS2) core-shell heterojunction and preparation method and application thereof

A niobium disulfide and heterojunction technology, applied in chemical instruments and methods, tin compounds, inorganic chemistry, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

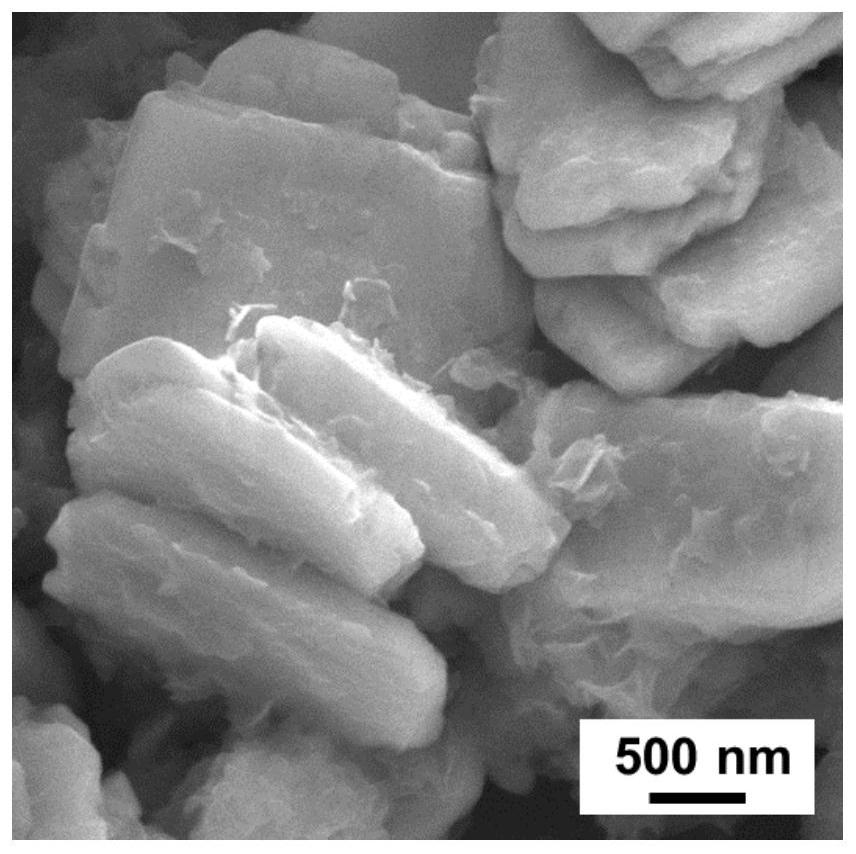

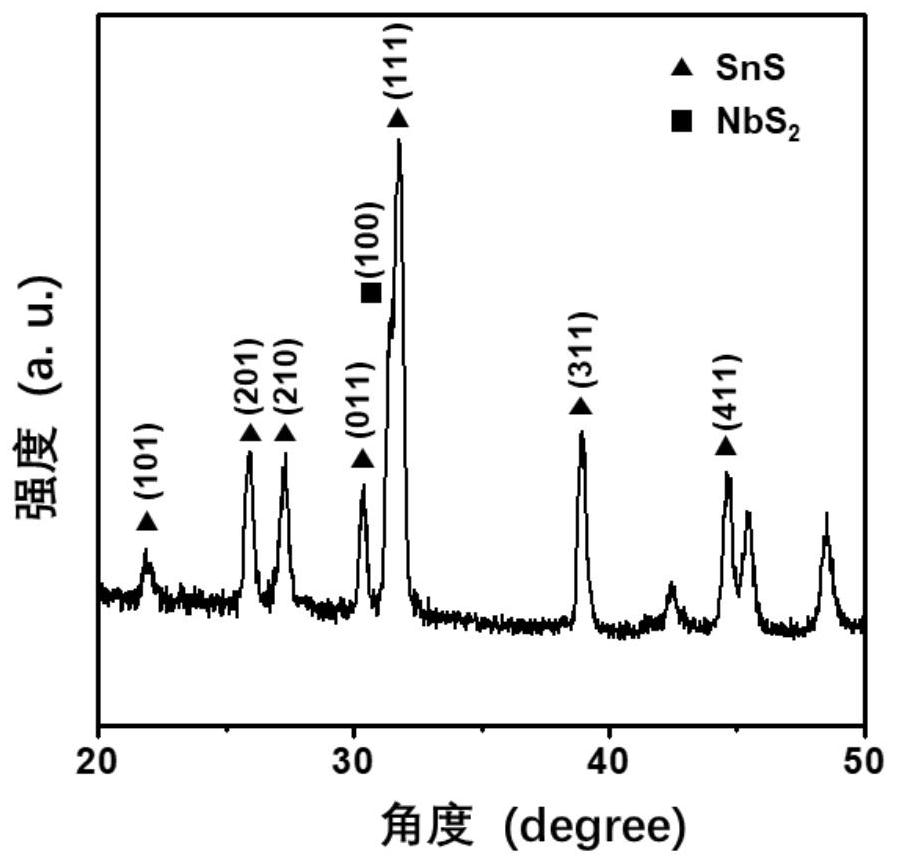

[0037] Example 1: SnS@NbS 2 Preparation method of core-shell heterogeneity

[0038] Dissolve niobium pentachloride (0.23 mmol × 0.3) and tin tetrachloride pentahydrate (0.23 mmol × 0.7) in 20 ml of oleylamine, and degas at 100 °C for 15 min under an ultra-high-purity argon atmosphere to remove air and impurities while rigorously mixing. Subsequently, the mixture was heated to 300° C., and 8 mmol of carbon disulfide was injected into the solution through a syringe. After 1 hour, the reaction was stopped and the heat source was removed to cool to room temperature. The synthesized solution was washed by adding excess mixture of ethanol and isopropanol (volume ratio 1:3), and then centrifuged in a centrifuge at 8500 rpm for 5 min to isolate the synthesized SnS@NbS 2 Nucleocapsid heterogeneity. The obtained heterojunctions were then dispersed in n-hexane, and the centrifuge tube was sonicated to obtain a macroscopically homogeneous solution. Next, the mixture of excess ethanol...

Embodiment 2

[0040] Example 2: SnS@NbS 2 Preparation method of core-shell heterogeneity

[0041] Dissolve niobium pentachloride (0.23 mmol × 0.2) and tin tetrachloride pentahydrate (0.23 mmol × 0.8) in 20 ml of oleylamine, and degas at 120 °C for 15 min under an ultra-high-purity argon atmosphere to remove air and impurities while rigorously mixing. Subsequently, the mixture was heated to 300° C., and 8 mmol of carbon disulfide was injected into the solution through a syringe. After 1 hour, the reaction was stopped and the heat source was removed to cool to room temperature. The synthesized solution was washed by adding excess mixture of ethanol and isopropanol (volume ratio 1:3), and then centrifuged in a centrifuge at 8500 rpm for 5 min to isolate the synthesized SnS@NbS 2 Core-shell heterojunction. The obtained heterojunctions were then dispersed in n-hexane, and the centrifuge tube was sonicated to obtain a macroscopically homogeneous solution. Next, the mixture of excess ethanol an...

Embodiment 3

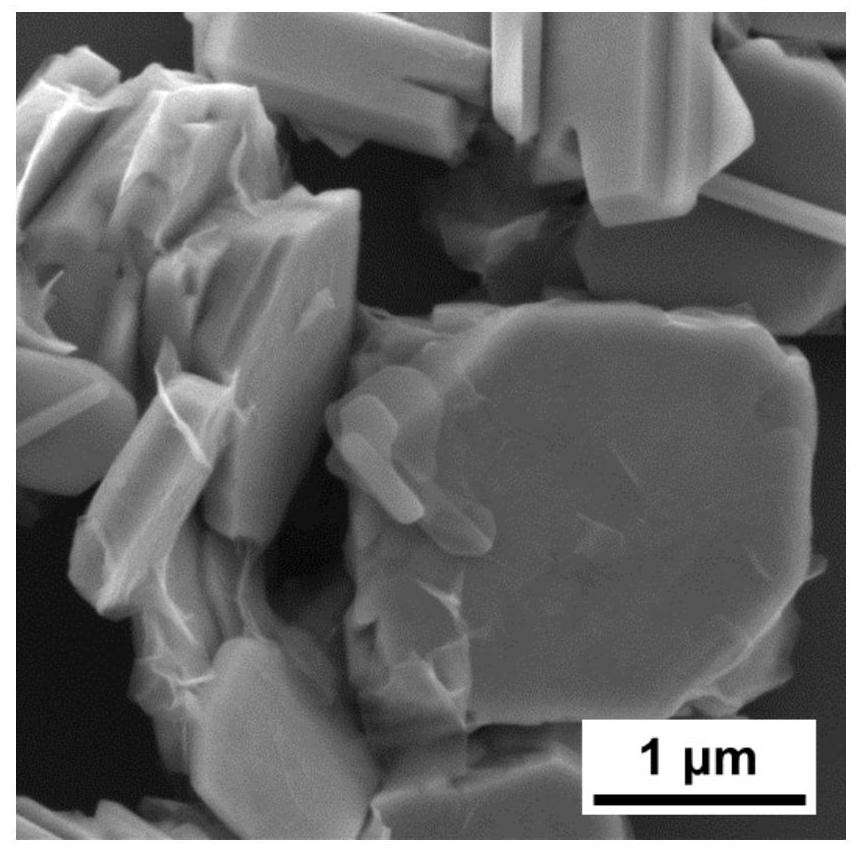

[0043] Example 3: SnS@NbS 2 Preparation method of core-shell heterogeneity

[0044] Dissolve niobium pentachloride (0.23 mmol × 0.4) and tin tetrachloride pentahydrate (0.23 mmol × 0.6) in 20 ml of oleylamine, and degas at 100 °C for 15 min under an ultra-high-purity argon atmosphere to remove air and impurities while rigorously mixing. Subsequently, the mixture was heated to 350° C., and 8 mmol of carbon disulfide was injected into the solution through a syringe. After 15 minutes, the reaction was stopped and the heat source was removed to cool to room temperature. The synthesized solution was washed by adding excess mixture of ethanol and isopropanol (volume ratio 1:3), and then centrifuged in a centrifuge at 8500 rpm for 5 min to isolate the synthesized SnS@NbS 2 Nucleocapsid heterogeneity. The obtained heterojunctions were then dispersed in n-hexane, and the centrifuge tube was sonicated to obtain a macroscopically homogeneous solution. Next, the mixture of excess eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com