Preparation method of high-purity lithium bis(oxalato)borate

A lithium bis-oxalate borate and high-purity technology is applied in the field of preparation of high-purity lithium bis-oxalate borate, and can solve the problems of difficulty in obtaining raw materials for synthesis routes, difficulty in industrial production, and low synthesis efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

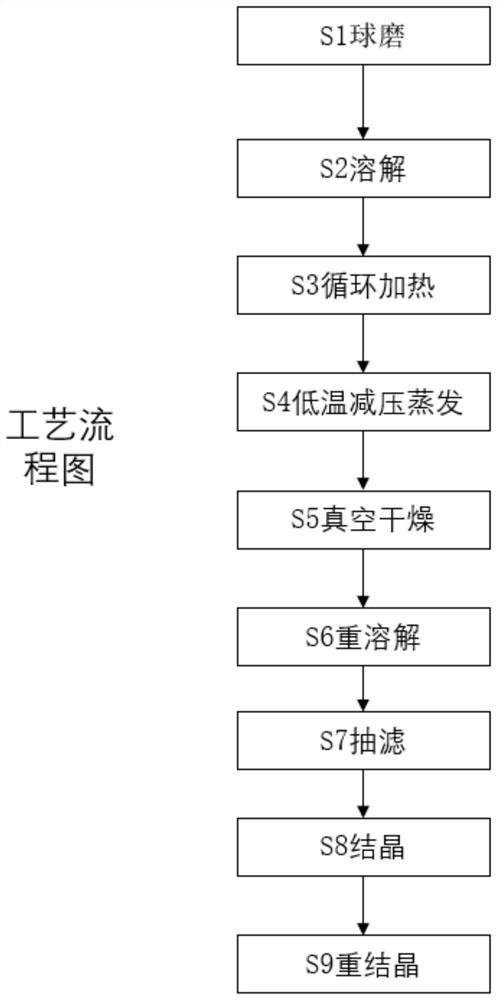

[0039] A preparation method of high-purity lithium bisoxalate borate comprises the following specific steps:

[0040] S1 ball milling: uniformly mix anhydrous oxalate and boron in a molar ratio of 2:1, put them into a ball mill and mill for 0.5h, then dissolve the mixed powder into ultrapure water at a mass ratio of 1:20 to obtain solution A;

[0041] S2 Dissolving: Lithium powder is dissolved in ethylene carbonate according to the mass ratio of 1:10 to obtain solution B;

[0042] S3 cycle heating; put the A liquid and B obtained in steps S1 and S2 into the tubular reactor according to the mass ratio of 1:2 for heating reaction, the reaction temperature is 60 ° C; micro-negative pressure reaction, the pressure is -0.001Mpa; The moisture generated under negative pressure forms an azeotrope with diethyl carbonate at high temperature and is discharged out of the system under negative pressure; diethyl carbonate and water are separated in the static tank, and diethyl carbonate is ...

Embodiment 2

[0050] A preparation method of high-purity lithium bisoxalate borate comprises the following specific steps:

[0051] S1 ball milling: uniformly mix anhydrous oxalate and boron in a molar ratio of 3.5:1, put them into a ball mill for 1 hour, and then dissolve the mixed powder into ultrapure water at a mass ratio of 1:30 to obtain solution A;

[0052] S2 dissolution: Lithium powder is dissolved in ethylene carbonate according to the mass ratio of 1:15 to obtain solution B;

[0053] S3 cycle heating; put the A liquid and B obtained in steps S1 and S2 into the tubular reactor according to the mass ratio of 1:3 for heating reaction, the reaction temperature is 68 ° C; micro-negative pressure reaction, the pressure is -0.001Mpa; The moisture generated under negative pressure forms an azeotrope with diethyl carbonate at high temperature and is discharged out of the system under negative pressure; diethyl carbonate and water are separated in the static tank, and diethyl carbonate is ...

Embodiment 3

[0061] A preparation method of high-purity lithium bisoxalate borate comprises the following specific steps:

[0062] S1 ball milling: uniformly mix anhydrous oxalate and boron in a molar ratio of 5:1, put them into a ball mill and mill for 1.5 hours, then dissolve the mixed powder into ultrapure water at a mass ratio of 1:50 to obtain solution A;

[0063] S2 Dissolving: Lithium powder is dissolved in ethylene carbonate according to the mass ratio of 1:20 to obtain solution B;

[0064] S3 cycle heating; put the A liquid and B obtained in steps S1 and S2 into the tubular reactor according to the mass ratio of 1:5 for heating reaction, the reaction temperature is 75 °C; slight negative pressure reaction, the pressure is -0.001Mpa; The moisture generated under negative pressure forms an azeotrope with diethyl carbonate at high temperature and is discharged out of the system under negative pressure; diethyl carbonate and water are separated in the static tank, and diethyl carbonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com