Application of sdr family oxidoreductase e26 as emulsifier

A reductase, E26 technology, applied in the directions of oxidoreductase, resistance to vector-borne diseases, liquid carbon-containing fuel, etc., to achieve the effect of tolerance to pH environment, good emulsification effect, and wide pH environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This example illustrates the recombinant engineered bacteria Escherichia coli Construction of BL21-pET-e26.

[0051] Using PCR technology, from wild bacteria Aeribacillus pallidus The SDR family oxidoreductase E26 gene e26 was amplified from the SL-1 genomic DNA, and the e26 gene was connected to the multiple cloning site of the expression vector pET28, and the recombinant plasmid pET28-e26 was transformed into E. coli Genetically engineered bacteria obtained from BL21(DE3) Escherichia coli BL21-pET-e26.

[0052] The above construction methods specifically include:

[0054] According to wild mushroom Aeribacillus pallidus Design primers for the e26 gene sequence in the SL-1 genome sequencing results:

[0055] P1: 5'-CGGGATCCCGATGTTAACAAATCAAGTAGC-3' (BamH I)

[0056] P2: 5’- CCAAGCTTGGTGCAATAGGATATTGTTGAA-3’ (Hind III)

[0057] PCR reaction system: ddH 2 O 20 µL, High Fidelity Enzyme Mix 25 µL, Primer P1 2 µL, Primer P2 2 ...

Embodiment 2

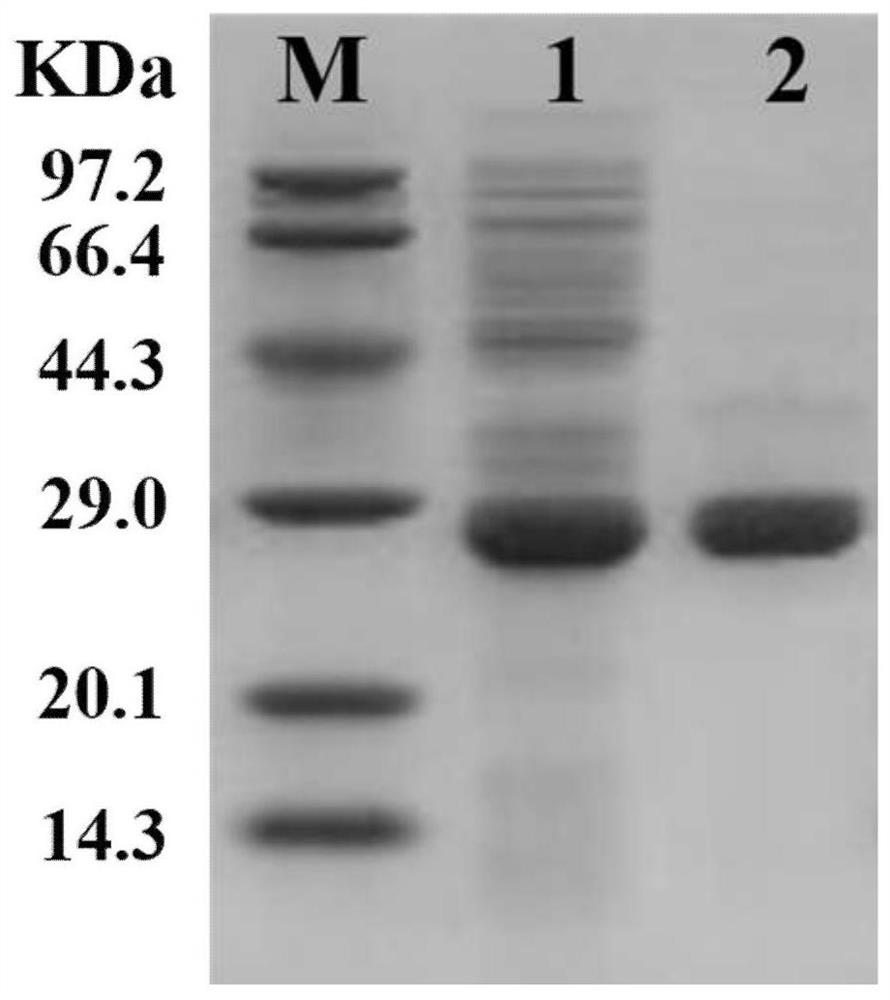

[0061] This example illustrates the acquisition of the SDR family oxidoreductase E26.

[0062] (1) Induced expression of SDR family oxidoreductase E26:

[0063] Medium: LB medium: yeast powder 5 g / L, peptone 10 g / L, sodium chloride 10 g / L.

[0064] Culture conditions: 50 mL of liquid in a 250 mL Erlenmeyer flask, culture temperature 37°C, 200 rpm, culture until OD600 reaches 0.6-0.8, add 1 mM IPTG to induce the expression of SDR family oxidoreductase E26. After culturing for 12 hours at 28°C and 200 rpm, the cells were collected by centrifugation at 10,000×g for 10 min. The cells were resuspended in 50 mM Tris-HCl buffer, pH 7.4, and the cells were crushed by a high-pressure homogenizer, centrifuged at 10,000×g for 20 min, and the supernatant was discarded, which was the crude enzyme solution.

[0065] (2) Determination of protein amount: the protein amount was measured by the Brandford method.

[0066] Production of protein standard song:

[0067] Prepare Coomassie Brilli...

Embodiment 3

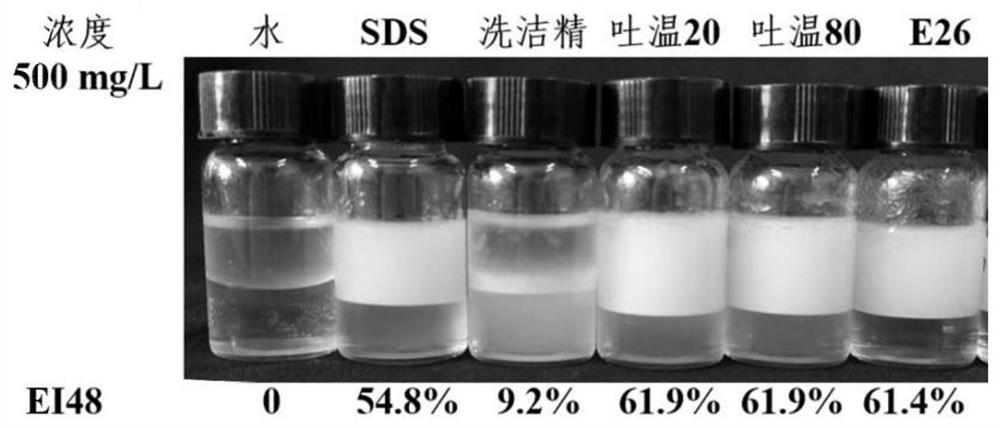

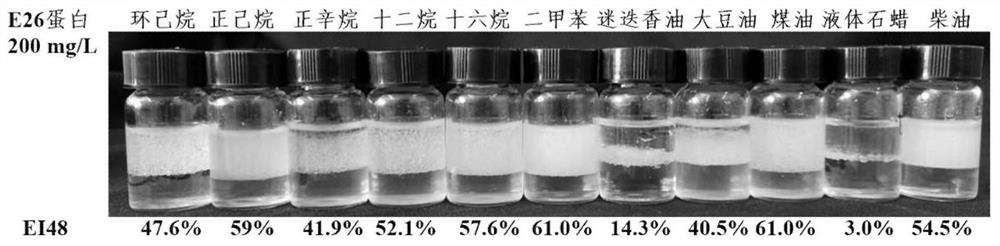

[0075] This example illustrates the emulsifying activity assay method.

[0076] Using different hydrocarbons as emulsification objects, in a 5mL volumetric glass bottle, add the purified enzyme solution in Example 2 to the buffer solution (50 mM Tris-HCl pH7.8), the total volume is 2 mL, and mix with the oil phase Mix at a volume ratio of 1:1, vortex for 2 minutes, and let stand for 48 hours.

[0077] Emulsification index (EI48) is calculated by multiplying the ratio of the height of the emulsified layer to the total height by 100% to represent the emulsifying activity of the emulsifier.

[0078] Emulsification index (EI48) = (emulsion layer height) / (total liquid height) × 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com