Method for determining content of phenoxyacetic acid in phenoxyacetic acid tested sample

A technology based on phenoxyacetic acid and phenoxyacetic acid, applied in the field of chemical analysis, can solve problems such as poor accuracy, high toxicity of reagents, and susceptibility to impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

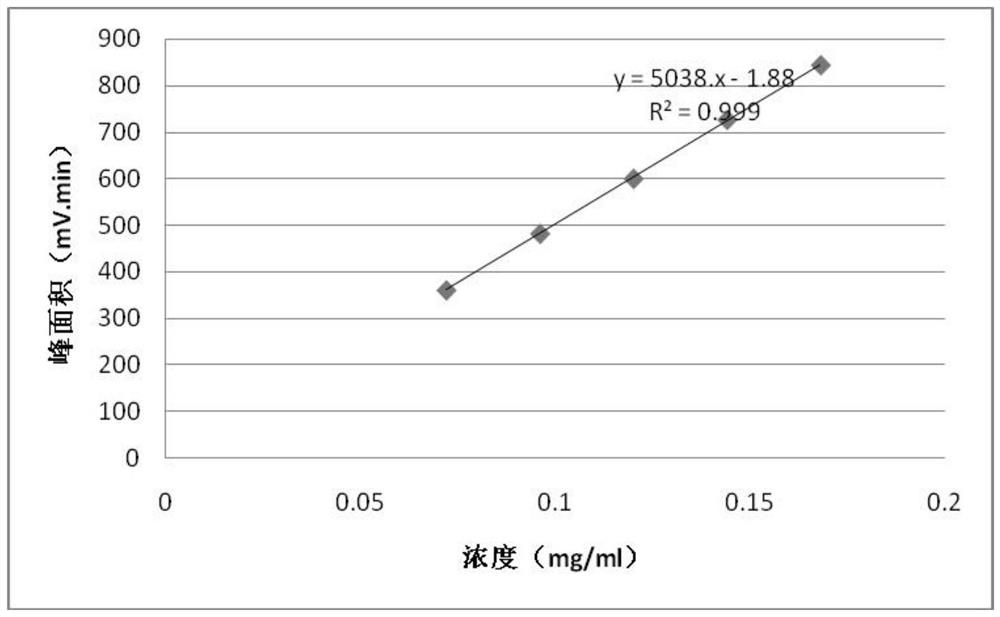

[0031] (a) Preparation of reference substance solution: Accurately weigh the phenoxyacetic acid standard substance, add mobile phase to dissolve, and quantitatively dilute to make the concentration Ca 1 (0.02~0.5mg / mL) phenoxyacetic acid standard reference solution, shake well, and dilute to volume;

[0032] (b) Preparation of the tested sample solution: Accurately weigh the phenoxyacetic acid sample, add mobile phase to dissolve, and quantitatively dilute to make a phenoxyacetic acid tested sample solution with a concentration of Ca (0.02-0.5 mg / mL), shake well ,Volume;

[0033] (c) Chromatographic conditions: Octadecylsilane bonded silica gel is used as a filler, and a mixed solution of water, methanol, and pH 3.5 phosphate aqueous solution with a volume ratio of 100:80:20 is used as a mobile phase, and the flow rate is 1.4mL / min; the detection wavelength is 220nm; the column temperature is 25°C; the number of theoretical plates should not be less than 2000 based on the ma...

Embodiment 1

[0041] Chromatographic conditions: using Elite C 18 The reverse phase column is 4.6mm×150mm, 5μm; the mobile phase is a mixed solution of water, methanol and pH3.5 phosphate aqueous solution with a volume ratio of 100:80:20; the flow rates are 1.0mL / min, 1.4mL / min and 2.0mL / min; UV detector, the detection wavelength is 292nm; column temperature is 25°C (room temperature); the number of theoretical plates should not be less than 2000 based on the main peak.

[0042] Sample solution to be tested: Accurately weigh the phenoxyacetic acid sample, add mobile phase to dissolve and quantitatively dilute to make a solution containing 0.02mg of phenoxyacetic acid sample per 1mL, shake well, and constant volume;

[0043] Reference substance solution: Accurately weigh the phenoxyacetic acid standard, add mobile phase to dissolve, and quantitatively dilute to make a solution of 0.02mg phenoxyacetic acid standard in every 1mL, shake well, and constant volume;

[0044] Determination method:...

Embodiment 2

[0052] The chromatographic conditions are the same as in Example 1.

[0053] Sample solution to be tested: Accurately weigh the phenoxyacetic acid sample, add mobile phase to dissolve and quantitatively dilute to make a solution containing 0.2mg of phenoxyacetic acid sample per 1mL, shake well, and constant volume;

[0054] Reference substance solution: Accurately weigh the phenoxyacetic acid standard, add mobile phase to dissolve, and quantitatively dilute to make a solution containing 0.2mg of phenoxyacetic acid standard per 1mL, shake well, and constant volume;

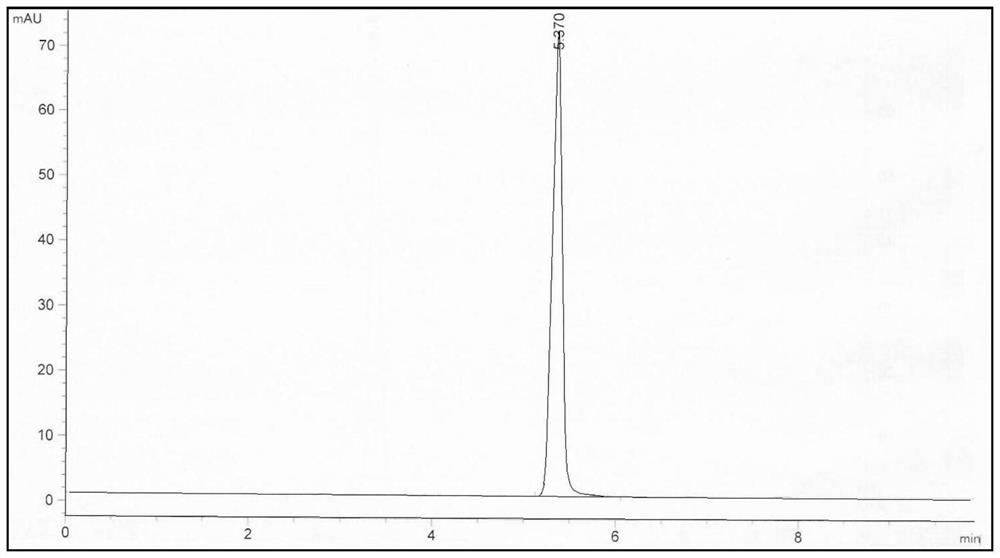

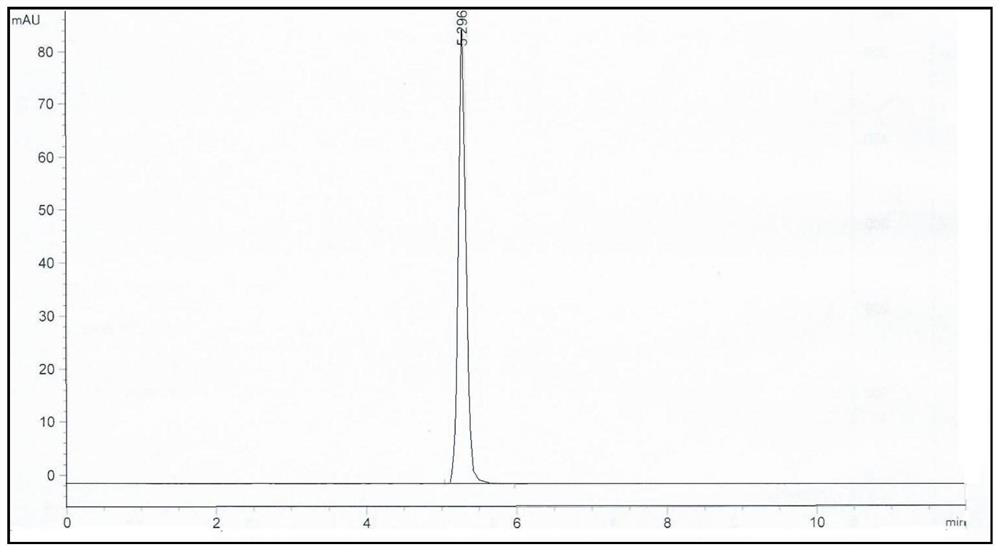

[0055] Determination method and the step of calculating phenoxyacetic acid content are identical with embodiment 1, and the chromatogram of phenoxyacetic acid standard substance and phenoxyacetic acid sample is as follows Figure 1~2 As shown, the contents of phenoxyacetic acid in the calculated samples were 96.7%, 98.2% and 96.8%, respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com