Method for manufacturing capillary filled column plunger by using photonic crystal fiber and application

A technology of photonic crystal fiber and capillary, which is applied in separation methods, chemical instruments and methods, solid adsorbent liquid separation, etc. It can solve the problems of poor repeatability, long preparation time, poor controllability of pore structure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

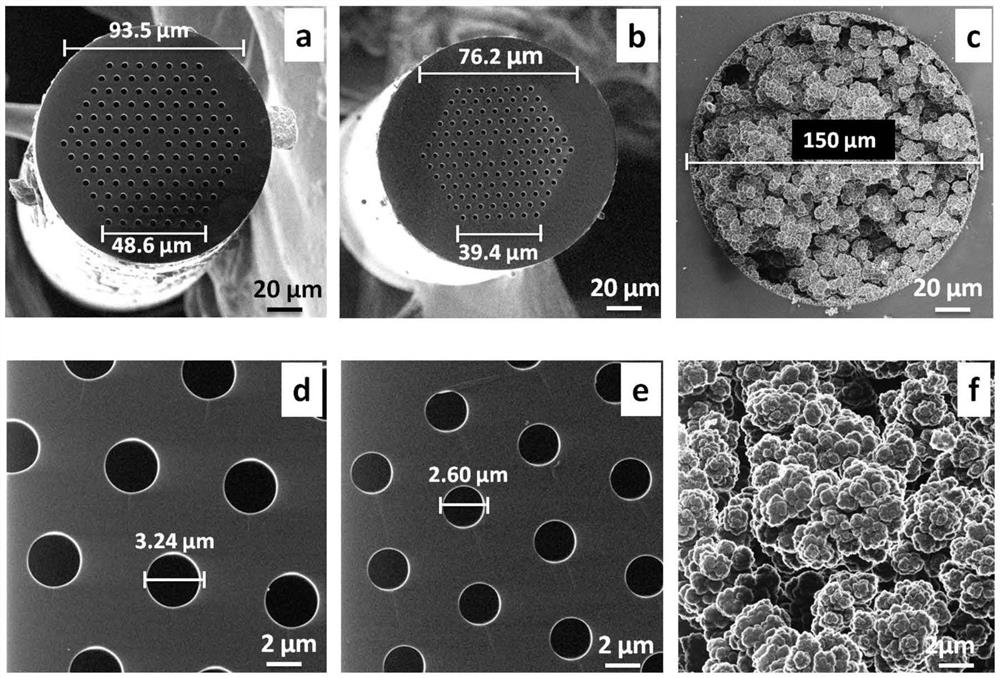

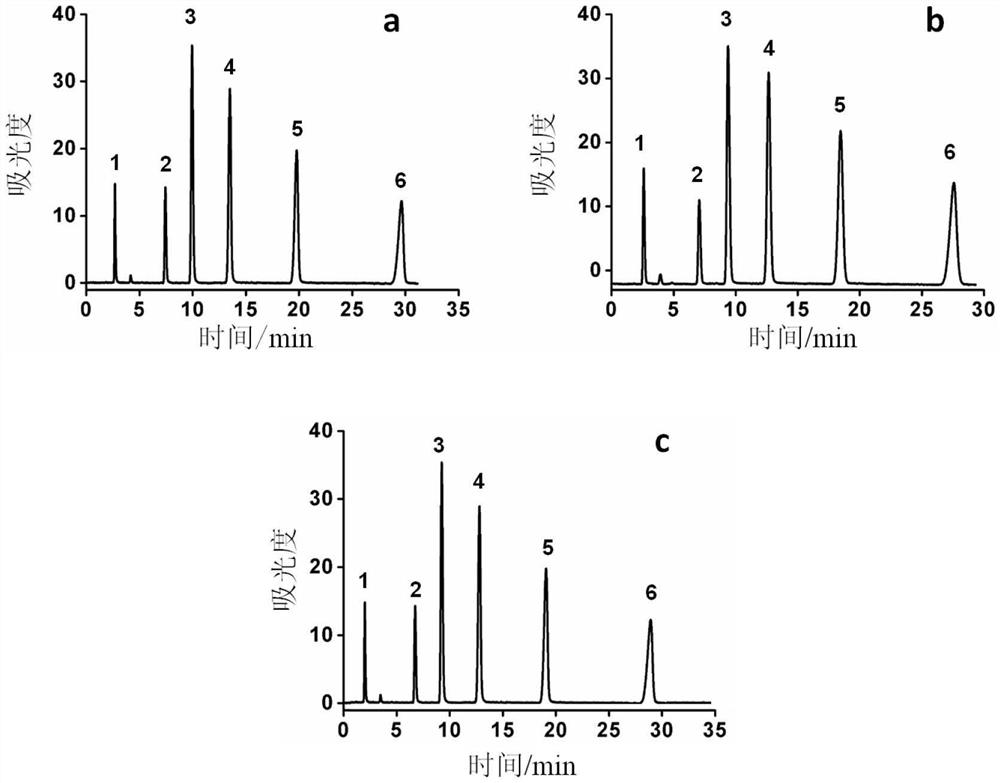

[0021] Example 1 Using photonic crystal fiber as the plunger to prepare a capillary packed column

[0022] 1) Cut the photonic crystal fiber-1 (outer diameter 125μm, cladding layer 10um, containing 126 air holes with a diameter of 3.2μm) into a length of 1cm, soak in 2mL of toluene solution for 10min, make the outer wall of the fiber cladding layer Swell, then carefully remove the fiber with tweezers and remove the coating;

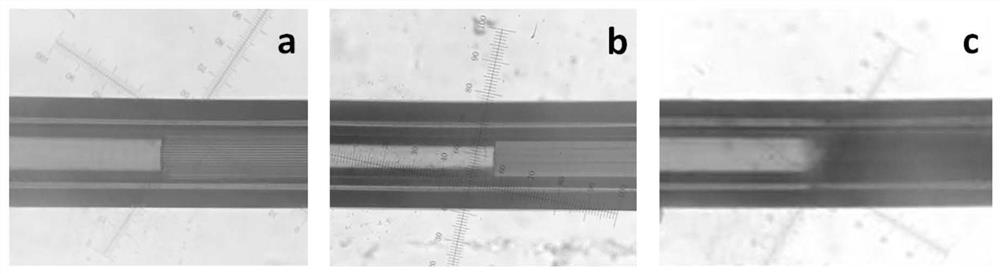

[0023] 2), apply the potting glue (Dow Corning PDMS-184 glue, USA) evenly on the outer wall of the optical fiber, and then insert it into a 30cm empty capillary (outer diameter 360μm, inner diameter 150μm);

[0024] 4) Put the capillary tube with the optical fiber plunger into an oven at 80°C for 2 hours, so that the epoxy resin glue can be fully cured before use;

[0025] 4), use the homogenization method to fill the capillary column with 3 μm C18 silica gel as the filler. The length of the plunger is 1 cm, and the length of the packing is 25 cm for ch...

Embodiment 2

[0026] Example 2 Using photonic crystal fiber as plunger to prepare capillary packed column

[0027] 1) Cut the photonic crystal fiber-2 (outer diameter 125μm, cladding layer 10um, containing 126 air holes with a diameter of 2.6μm) into a length of 1cm, soak in 2mL of toluene solution for 10min, make the outer wall of the fiber cladding layer Swell, then carefully remove the fiber with tweezers and remove the coating;

[0028] 2), apply the potting glue (Dow Corning PDMS-184 glue, USA) evenly on the outer wall of the optical fiber, and then insert it into a 30cm empty capillary (outer diameter 360μm, inner diameter 150μm);

[0029] 4) Put the capillary tube with the optical fiber plunger into an oven at 80°C for 2 hours, so that the epoxy resin glue can be fully cured before use;

[0030] 4), use the homogenization method to fill the capillary column with 3 μm C18 silica gel as the filler. The length of the plunger is 1 cm, and the length of the packing is 25 cm for chromato...

Embodiment 3

[0031] Example 3 Using porous organic monolithic column as plunger to prepare capillary packed column

[0032] 1), activate the inner wall of an empty capillary (outer diameter 360 μm, inner diameter 150 μm). The UV-transparent capillary was rinsed with 0.1mol / L NaOH aqueous solution (1h), deionized water (0.5h), 0.1mol / L HCl aqueous solution (4h), deionized water (0.5h) and methanol (0.5h) in turn, and then in Dry under nitrogen flow;

[0033] 2) The inner wall of the empty capillary (outer diameter 360 μm, inner diameter 150 μm) is vinyl functionalized. The methanol solution (1:1, v / v) of γ-(methacryloyloxy)propyltrimethoxysilane (γ-MAPS) was injected into the capillary. After the solution was filled, both ends of the capillary were sealed with silica gel sheets. Incubate and put it in a 50°C water bath for 12h; finally rinse the capillary with methanol (1h), and dry it under nitrogen flow;

[0034] 3), to prepare a prepolymer solution. Pipette 170 μL of n-butanol and 13...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com