Preparation method of silicon carbide aerogel thermal insulation material

A thermal insulation and aerogel technology, applied in the direction of silicon carbide, carbide, etc., can solve the problem of excessive thermal conductivity growth, and achieve the effects of small shrinkage, low density and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First add 1000 mesh graphite powder and 800 mesh silicon carbide powder to the silica sol with a content of 20%-25%, the ratio of the three parts by mass is 1.0: 3.0: 40, mix well to form a sol, and then mix the sol Pour the solution into a mold equipped with polyacrylonitrile-based carbon fiber material, so that the liquid surface of the sol is just submerged in the polyacrylonitrile-based carbon fiber material, and let it stand for 10-30 minutes to gel; then add a certain amount of ethanol solvent as an aging solution. Replace the excess water in the gel, the aging temperature is 35-80°C, the aging standing time is 12-72 hours, and the alcohol gel is obtained; after supercritical drying, the drying pressure is 10-25MPa, and the drying temperature is 80-100 After ℃, the silicon carbide airgel reinforced fiber material is obtained;

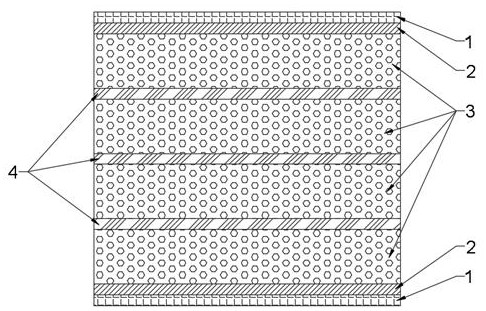

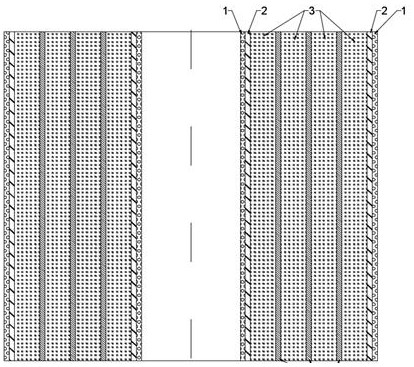

[0026] 2) if figure 1 or figure 2 As shown, the silicon carbide airgel reinforced fiber material layer 3 in step 1) is combined with fo...

Embodiment 2

[0028] Mix graphite powder, silicon carbide powder, and silica sol evenly according to the mass fraction ratio of 0.5:0.6:20, pour it into a mold equipped with polyacrylonitrile-based carbon fiber felt, make the sol liquid level just submerge the carbon fiber felt, and let it stand for 20 minutes To obtain the gel material, use ethanol solvent as the aging solution to replace the excess water in the gel, seal it and age it at 55°C for 14 hours to obtain an alcohol gel, and dry it supercritically at 18MPa and 85°C to obtain silicon carbide aerosol Glue reinforced polyacrylonitrile based fiber material. like figure 1 As shown, the silicon carbide airgel reinforced fiber 3 is multi-layer compounded, and the two surfaces are bonded with 1.0mm thick carbon paper 1 and 0.5mm thick carbon fiber cloth 2, which are bonded with epoxy resin adhesive layer 4 in turn. At the same time, the silicon carbide airgel insulation board insulation material is obtained after high temperature treat...

Embodiment 3

[0030] Mix graphite powder, silicon carbide powder, and silica sol evenly according to the mass fraction ratio of 0.8:1.2:35, pour it into a mold equipped with viscose-based carbon fiber felt, make the sol liquid level just submerge the carbon fiber felt, and stand for 25 minutes to obtain Gel material, using ethanol solvent as the aging solution to replace the excess water in the gel, after sealing, aging at 35°C for 48 hours to obtain alcohol gel, and supercritical drying at 20MPa and 65°C to obtain silicon carbide airgel Reinforced viscose based fiber material. like figure 1 As shown, the silicon carbide airgel reinforced fiber 3 is multi-layered, and the two surfaces are bonded with 0.8mm thick carbon paper 1 and 1.0mm thick carbon fiber cloth 2, and then bonded together with phenolic resin adhesive 4, After high temperature treatment at 1600°C, the silicon carbide airgel insulation board insulation material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com