Preparation method of boron carbide granulation powder for pressureless sintering

A technology of boron carbide and granulated powder, which is applied in the field of preparation of boron carbide granulated powder for pressureless sintering, which can solve the problems of poor mechanical properties and difficult density of pressureless sintered boron carbide, and achieve small particle size and accelerated densification Chemical process, the effect of increasing the specific surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

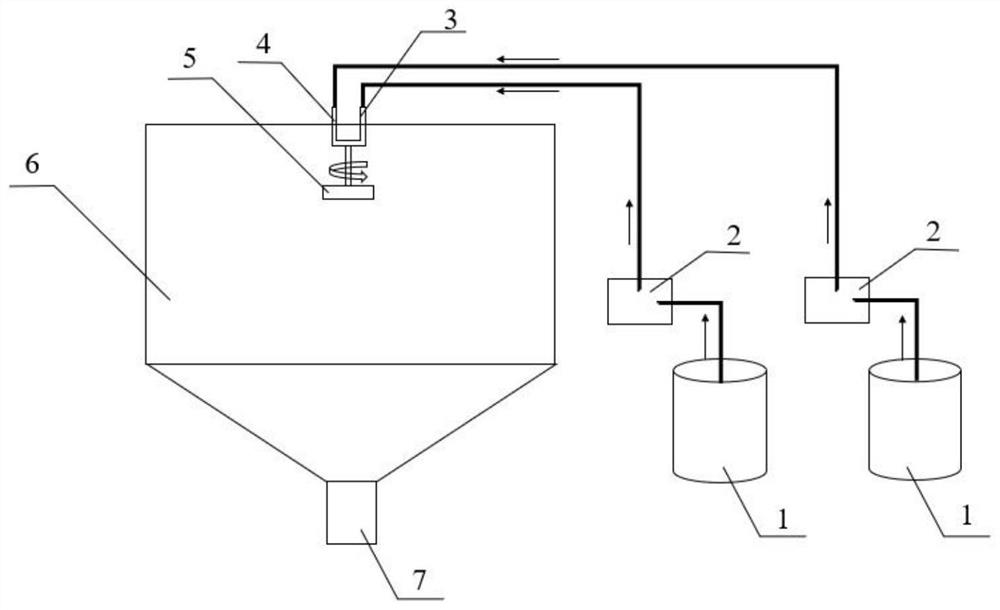

[0022] Specific embodiment one: the preparation method of a kind of boron carbide granulated powder for pressureless sintering in this embodiment is completed according to the following steps:

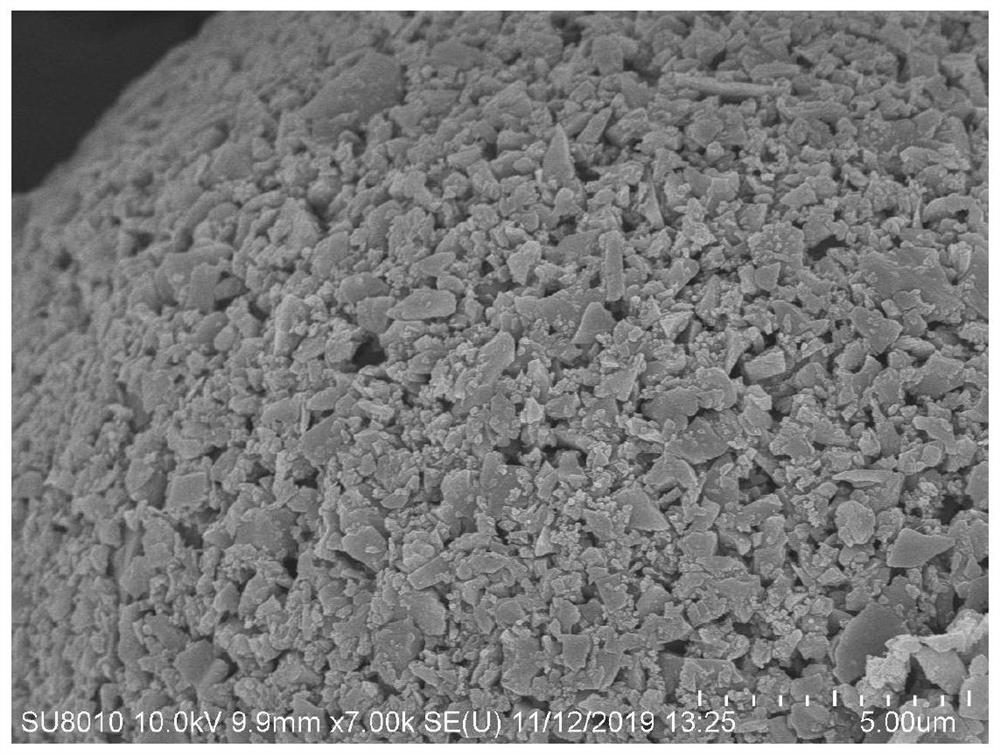

[0023] 1. Dispersion of raw materials: put the nano boron carbide powder in deionized water containing dispersant A to disperse evenly to obtain a nano boron carbide mixed liquid; place the micron boron carbide powder in deionized water containing dispersant B to disperse evenly to obtain micron boron carbide mixture;

[0024] 2. Mixing of raw materials: add sintering aid and binder to the nano boron carbide mixed liquid and micro boron carbide mixed liquid respectively, and ball mill and mix for 10-24 hours to obtain nano boron carbide slurry and micro boron carbide slurry respectively;

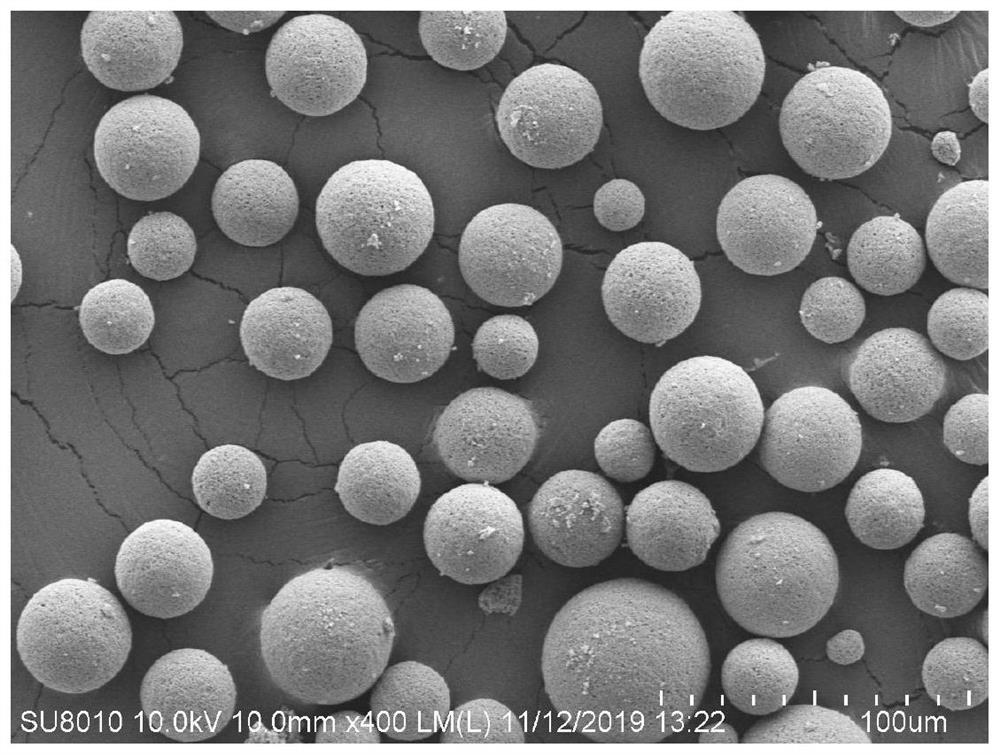

[0025] 3. Drying of raw materials: Pump the micron boron carbide slurry and nano boron carbide slurry into the atomizing pan through the two feed ports of the spray granulation tower, mix them in the...

specific Embodiment approach 2

[0033] Embodiment 2: This embodiment differs from Embodiment 1 in that: the particle size of the nano boron carbide powder described in step 1 is 20 nm to 600 nm, and the particle size distribution of the micron boron carbide powder is 0.6 μm to 50 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0034] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the mass ratio of nano boron carbide powder, micron boron carbide powder and deionized water is 1:1. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com