Method for preparing 2,5-furandicarboxaldehyde oxime through autocatalysis

A technology of furandicarbaldehyde oxime and furandicarbaldehyde, which is applied in the field of autocatalytic preparation of 2,5-furandimaldehyde oxime, which can solve the problems of cumbersome separation and purification steps, increased processing costs, and harsh reaction conditions, so as to reduce pollutant emissions , improve quality, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

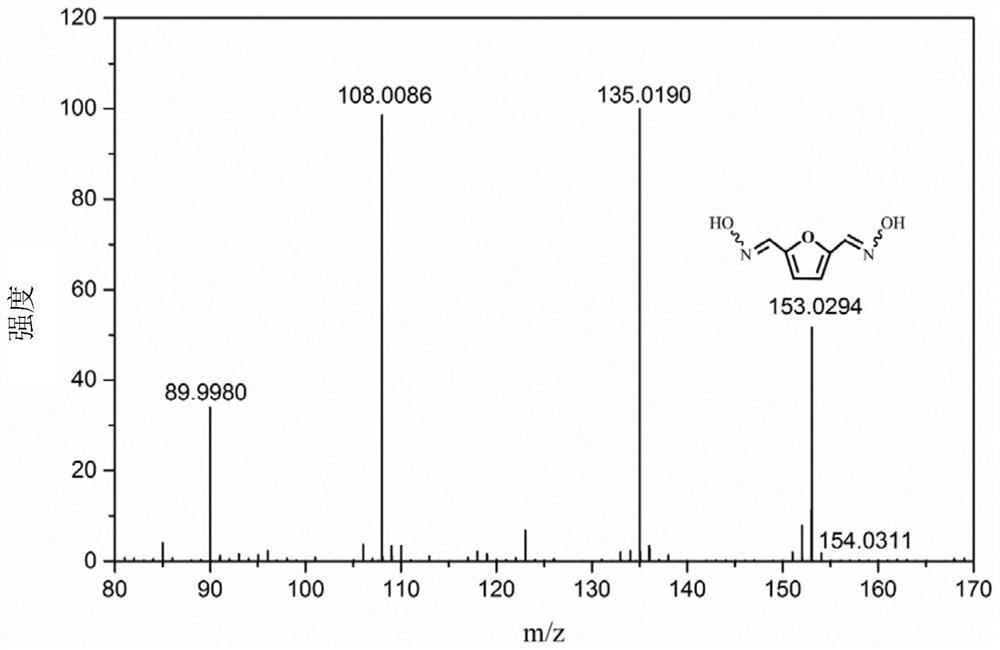

Image

Examples

preparation example Construction

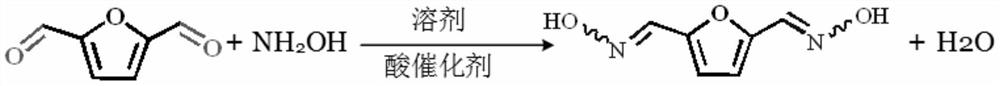

[0036] Further, the preparation method at least includes: adding an acid to adjust the initial pH value of the solution, starting the reaction of 2,5-furandicarbaldehyde and an oximating agent in a polar solvent, and the generated 2,5-furandicarbaldehyde oxime as a catalyst The reaction process is completed by self-catalysis; after the reaction is completed, it is naturally cooled to room temperature, filtered, washed and dried to obtain the target product 2,5-furandicarbaldehyde oxime.

[0037] In some embodiments, the method for autocatalytically preparing 2,5-furandicarbaldehyde oxime includes: after adding an acid into the liquid phase reaction system, the pH of the liquid phase reaction system is 1.0-7.0.

[0038] Further, the method includes: using acid to adjust the initial pH value of the liquid phase reaction system between 3.0 and 4.0. In the present invention, the pH value is between 3.0 and 4.0, which is more conducive to the attack of the nucleophile hydroxylamine o...

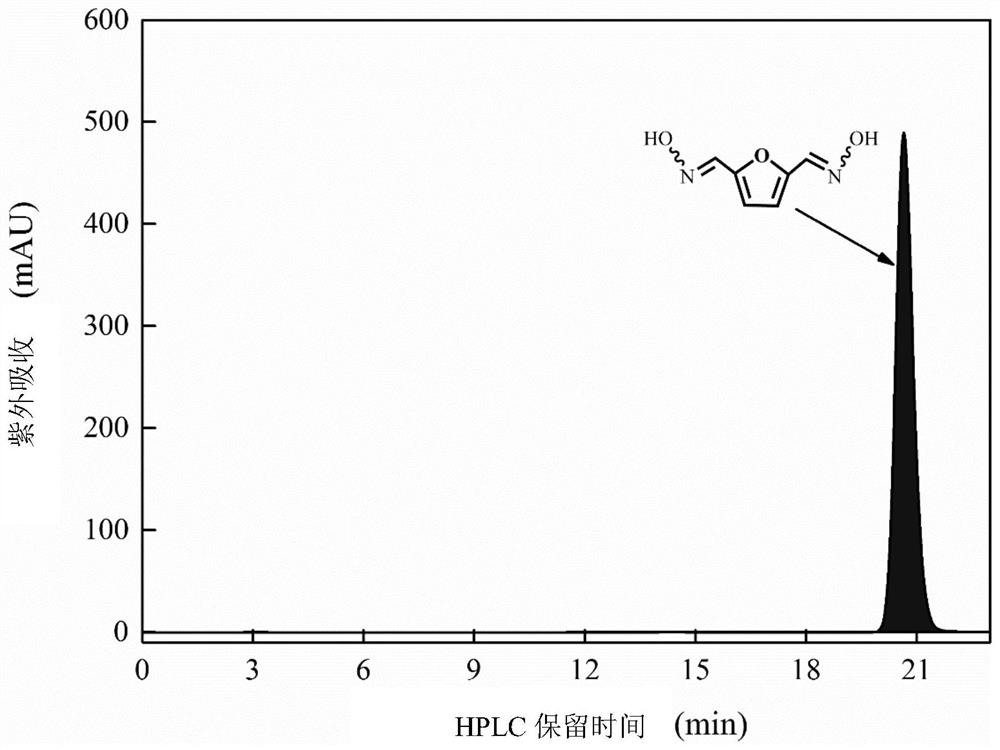

Embodiment 1

[0081] Mix 1mmol 2,5-furandicarbaldehyde, 2mL water and 4.0mmol 50wt.% hydroxylamine aqueous solution evenly, heat to 30°C, then add dilute hydrochloric acid with a content of 0.1wt.%, adjust the pH of the reaction system to 3.0, and continue the heat preservation reaction 5min, after the reaction was completed, cool down to room temperature naturally, filter the reaction product to obtain a precipitate, wash the precipitate with deionized water and dry at 100°C to obtain a white powder solid, which is the target product 2,5-furandicarbaldehyde oxime. According to the test, the selectivity of the product is 99.6%, and the purity is 99.8%.

Embodiment 2

[0083] Mix 2mmol 2,5-furandicarbaldehyde, 3mL ethanol and 6mmol 70wt.% hydroxylamine aqueous solution evenly, then add dilute sulfuric acid with a content of 0.5wt.%, adjust the pH of the reaction system to 4.0, react at room temperature (25°C) for 1min, and react After the end, cool naturally to room temperature, filter the reaction product to obtain a precipitate, wash the precipitate with deionized water and dry it at 100°C to obtain a white powder solid, which is the target product 2,5-furandicarbaldehyde oxime. After testing, the product The selectivity is 99.5%, and the purity is 99.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com