A kind of modified lignin and its preparation method and application in rubber composite materials

A composite material and lignin technology, applied to modified lignin and its preparation method and application in rubber composite materials, can solve the problems of poor reinforcement effect, limited application of lignin, weak binding effect, etc. The effect of improving compatibility and affinity, inhibiting self-aggregation tendency, and reducing molecular polarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

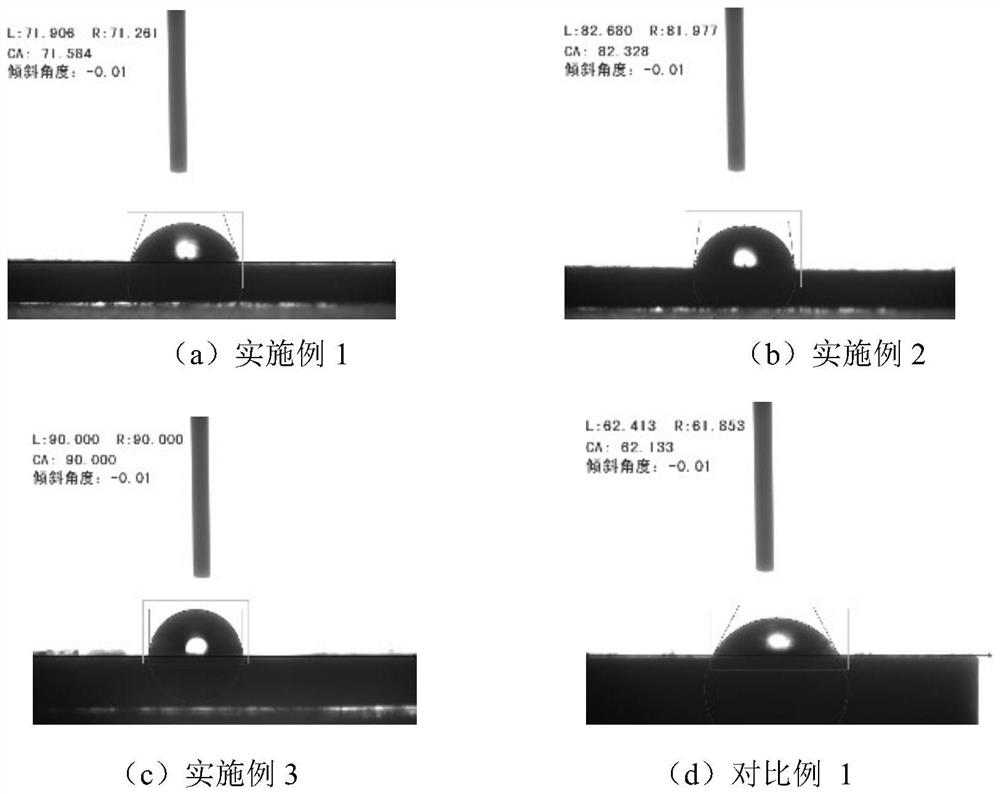

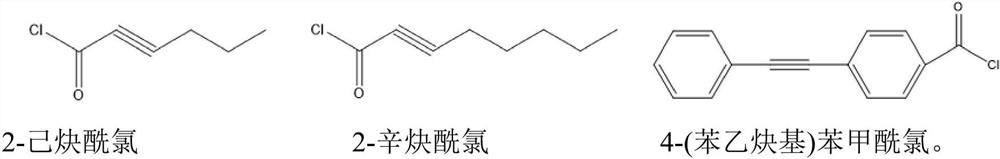

[0048] (1) Add alkali lignin and propioyl chloride into DMSO at a mass ratio of 100:18, the mass concentration of alkali lignin is 0.2g / mL, react at 60°C for 6 hours, cool to room temperature and add appropriate amount of deionized water to obtain Alkynylated lignin is precipitated, washed with deionized water until neutral, and vacuum-dried at 90°C for 24 hours to obtain alkynylated lignin;

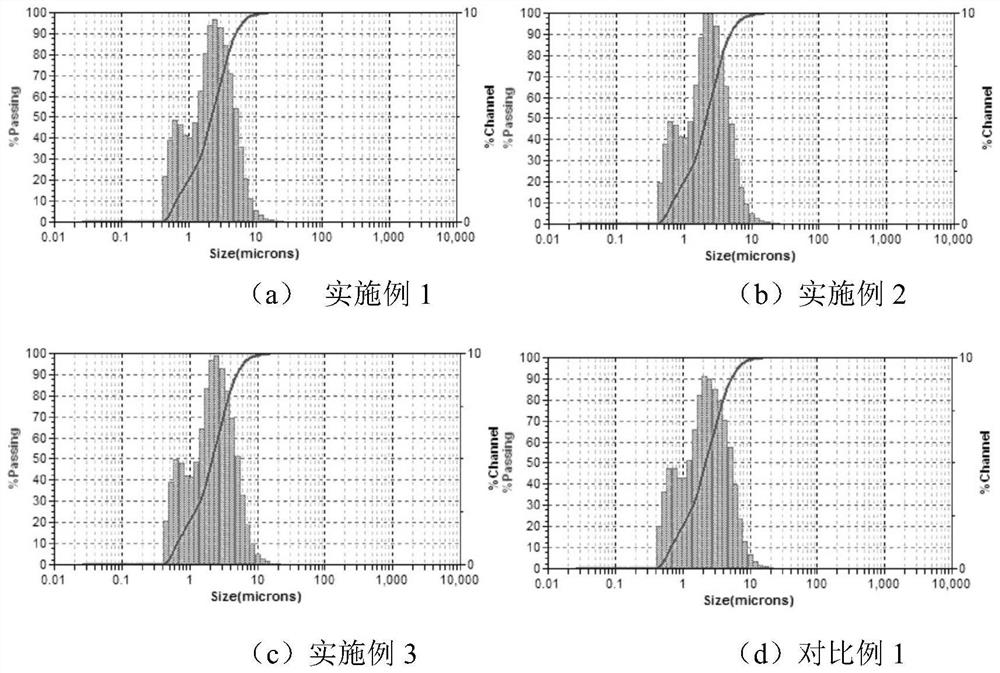

[0049] (2) the alkynylated lignin obtained in step (1) is ground to d by a jet mill 50 About 2.2μm;

[0050] (3) Accurately weigh 6.0g of the alkynylated lignin obtained in step (2), add 40.0g of natural rubber, 14.0g of carbon black N330, 2.0g of zinc oxide, and 1.2g of stearic acid into the internal mixer successively, and heat at 100°C 15 minutes of banburying under the same conditions;

[0051] (4) Put the mixed rubber obtained in the step (3) into the rolling mill, add 1.0 g of sulfur and 0.24 g of benzothiazole disulfide in turn, mix for 10 minutes at 20 ° C, and pass through 5 t...

Embodiment 2

[0053] (1) Add alkali lignin and propioyl chloride into DMSO at a mass ratio of 100:36, the mass concentration of alkali lignin is 0.2g / mL, react at 60°C for 6 hours, cool to room temperature and add appropriate amount of deionized water to obtain Alkynylated lignin is completely precipitated, washed with deionized water until neutral, and vacuum-dried at 90°C for 24 hours to obtain alkynylated lignin;

[0054] (2) the alkynylated lignin obtained in step (1) is ground to d by a jet mill 50 About 2.2μm;

[0055] (3) Accurately weigh 6.0g of the alkynylated lignin obtained in step (2), add 40.0g of natural rubber, 14.0g of carbon black N330, 2.0g of zinc oxide, and 1.2g of stearic acid into the internal mixer successively, and heat at 100°C 15 minutes of banburying under the same conditions;

[0056] (4) Put the mixed rubber obtained in the step (3) into the rolling mill, add 1.0 g of sulfur and 0.24 g of benzothiazole disulfide in turn, mix for 10 minutes at 20 ° C, and pass ...

Embodiment 3

[0058] (1) Add alkali lignin and propioyl chloride into DMSO at a mass ratio of 100:54, the mass concentration of alkali lignin is 0.2g / mL, react at 60°C for 6 hours, cool to room temperature and add appropriate amount of deionized water until Alkynylated lignin is precipitated, washed with deionized water until neutral, and vacuum-dried at 90°C for 24 hours to obtain alkynylated lignin;

[0059] (2) the alkynylated lignin obtained in step (1) is ground to d by jet milling 50 About 2.2μm;

[0060] (3) Accurately weigh 6.0g of the alkynylated lignin obtained in step (2), add 40.0g of natural rubber, 14.0g of carbon black N330, 2.0g of zinc oxide, and 1.2g of stearic acid into the internal mixer successively, and heat at 100°C 15 minutes of banburying under the same conditions;

[0061] (4) Put the mixed rubber obtained in the step (3) into the rolling mill, add 1.0 g of sulfur and 0.24 g of benzothiazole disulfide in turn, mix for 10 minutes at 20 ° C, and pass through 5 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com