A kind of waterborne acrylic acid modified alkyd resin and preparation method thereof

A water-based acrylic and alkyd resin technology, applied in coatings, polyester coatings, etc., can solve problems such as liver and kidney damage, animal reproductive system damage, and high toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

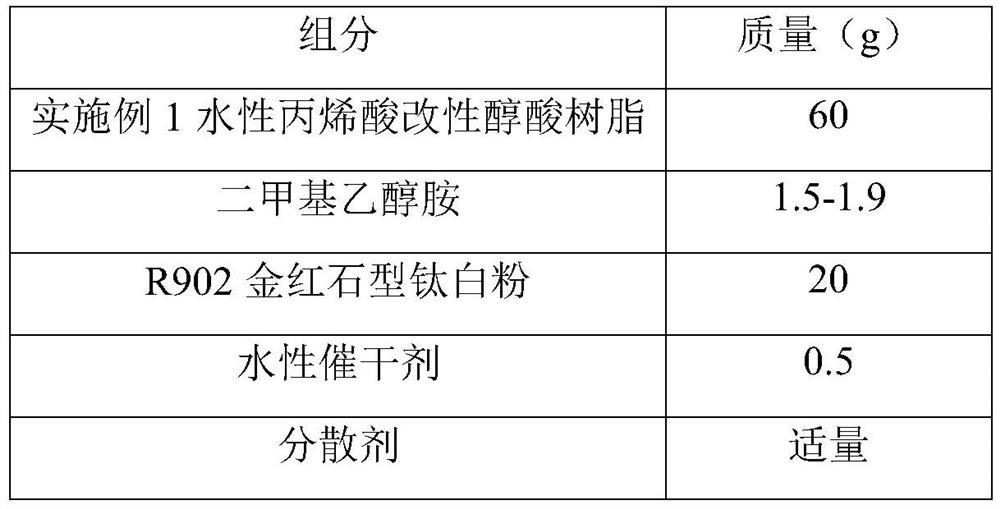

Examples

Embodiment 1

[0030] 1, a kind of water-based acrylic acid modified alkyd resin, it is made by the raw material of following percentage by weight: 22% soybean oil fatty acid, 14% trimethylolpropane, 13% phthalic anhydride, 0.05% hypophosphorous acid, 1% reflux xylene, 0.7% maleic anhydride, 2.5% trimellitic anhydride, 4% methyl methacrylate, 6% styrene, 1% butyl acrylate, 0.5% initiator dibenzoyl peroxide, 28% propylene glycol methyl ether.

[0031] 2, the preparation method of waterborne acrylic acid modified alkyd resin, comprises the following steps:

[0032] (1) 22% soybean oil fatty acid, 14% trimethylol propane, 13% phthalic anhydride, 0.05% hypophosphorous acid, 1% reflux xylene are dropped in the reactor by weight percentage, then be warming up to 180 ℃ of insulation 3 hours, use 2 Heat up from 180°C to 220°C within hours, and then reflux at 220°C-230°C for esterification. After reflux for 2 hours, start sampling to measure the acid value. Take it out and take a sample to measure t...

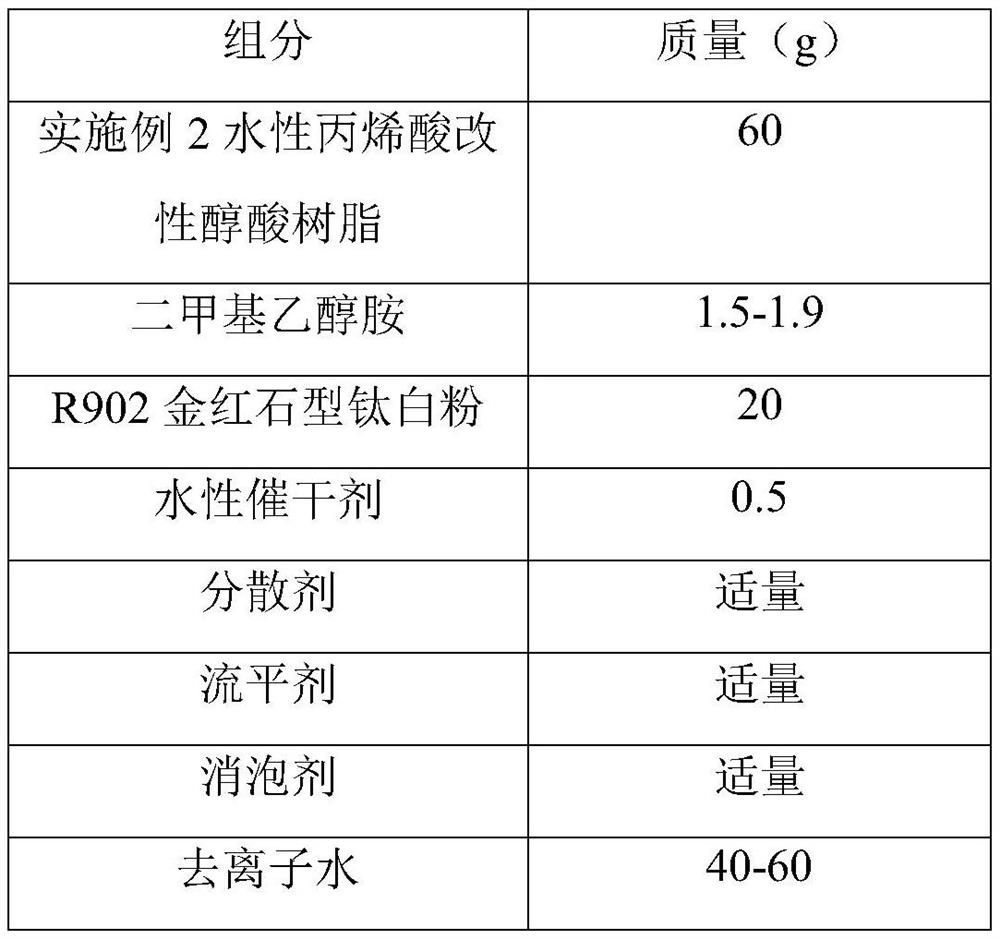

Embodiment 2

[0043] 1, a kind of water-based acrylic acid modified alkyd resin, it is made of the raw material of following percentage by weight: 12% sunflower oil acid, 12% linseed oil fatty acid, 15% trimethylolethane, 14% phthalic anhydride, 0.15% linoleic acid Triphenyl phosphate, 3% refluxed xylene, 1% maleic anhydride, 2.7% trimellitic anhydride, 5% methyl methacrylate, 8% styrene, 2% butyl acrylate, 1% initiator azobisiso Nitrile, 29% propylene glycol methyl ether.

[0044] 2, the preparation method of waterborne acrylic acid modified alkyd resin, comprises the following steps:

[0045] (1) 12% sunflower acid, 12% linseed oil fatty acid, 15% trimethylolethane / 14% phthalic anhydride, 0.15% triphenyl phosphite, 3% reflux xylene are dropped into the reactor by weight percentage, Then heat up to 180°C for 3 hours, then heat up from 180°C to 220°C in 2.5 hours, then reflux at 220°C-230°C for esterification, and start sampling to measure the acid value after reflux for 2 hours. When the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| luster | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com