Toluene-diisocyanate-modified alkyd resin and preparation method thereof

A technology of toluene diisocyanate and alkyd resin, which is applied in the field of toluene diisocyanate modified alkyd resin and its preparation, can solve the problems of increased resin viscosity, low resin molecular weight and viscosity increase, and can improve dry hardness and water resistance. high gloss, good water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

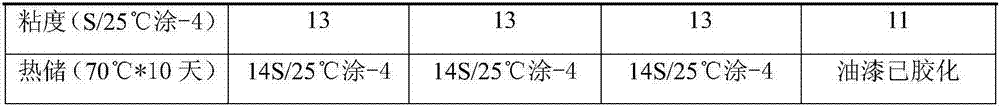

Embodiment 1

[0030] 1. A toluene diisocyanate modified alkyd resin, which is made of the following mass percentages of raw materials: 17% soybean oil fatty acid, 11% monopentaerythritol, 5% glycerin, 14% phthalic anhydride, 10% benzoic acid, 0.15% secondary Phosphoric acid, 5% toluene diisocyanate, 0.05% dibutyltin, 3% xylene, 34.8% toluene.

[0031] 2. Preparation method of toluene diisocyanate modified alkyd resin,

[0032] (1) Put the mass ratio of 17% soybean oil fatty acid, 11% monopentaerythritol, 5% glycerol, 14% phthalic anhydride, 10% benzoic acid, 0.15% hypophosphorous acid, 0.05% dibutyltin, and 3% xylene into the reactor , Heat up to 180°C for 3 hours, then heat up to 220°C in 2 hours, then heat to reflux at 220°C for esterification;

[0033] (2) After heating and refluxing the esterification reaction for 2 hours, start sampling to measure the acid value. When the acid value is less than or equal to 3mgKOH / g, start to cool down. When the kettle temperature drops to 180°C, add 34.8% t...

Embodiment 2

[0035] 1. A toluene diisocyanate modified alkyd resin, which is made of the following mass percentages of raw materials: 15% dry rapeseed oleic acid, 9% monopentaerythritol, 3% trimethylolpropane, 12% phthalic anhydride, 8 % Benzoic acid, 0.10% triphenyl phosphite, 4% toluene diisocyanate, 0.03% stannous octoate, 48.87% xylene.

[0036] 2. Preparation method of toluene diisocyanate modified alkyd resin,

[0037] (1) The mass ratio is 15% dry rapeseed oleic acid, 9% monopentaerythritol, 3% trimethylolpropane, 12% phthalic anhydride, 8% benzoic acid, 0.10% triphenyl phosphite and 1% Put toluene into the reaction kettle, heat up to 180°C for 3 hours, then heat up to 220°C in 3 hours, and then heat to reflux at 230°C for esterification;

[0038] (2) After heating and refluxing the esterification reaction for 2 hours, start sampling to measure the acid value. When the acid value is less than or equal to 3mgKOH / g, start to cool down. When the kettle temperature drops to 180°C, add 47.87% ...

Embodiment 3

[0040] A toluene diisocyanate modified alkyd resin, which is made of the following mass percentage of raw materials: 16% linseed oil fatty acid, 10% monopentaerythritol, 4% trimethylolethane, 13% phthalic anhydride, 9% benzoic acid , 0.10% color reducing agent, 4% toluene diisocyanate, 0.04% monobutyl tin oxide, 2% xylene, 41.86% trimethylbenzene.

[0041] (1) Put the mass ratio as follows: 16% linseed oil fatty acid, 10% monopentaerythritol, 4% trimethylolethane, 13% phthalic anhydride, 9% benzoic acid, 0.10% color reducing agent and 2% xylene. In the reactor, heat up to 190°C for 2 hours, then heat up to 220°C in 2 hours, and then heat to reflux at 230°C for esterification;

[0042] (2) After heating and refluxing the esterification reaction for 2 hours, start sampling to measure the acid value. When the acid value is less than or equal to 3mgKOH / g, start to cool down. When the kettle temperature drops to 180°C, add 47.87% toluene, and when the kettle temperature drops When it r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com