Polyimide film with high strength, high thermal stability, high transparency and low glass transition temperature and preparation method thereof

A technology of polyimide film and transition temperature, applied in the field of polymer materials, can solve the problems of unrecyclable harmful catalysts, complicated reaction steps, incomplete imidization, etc., achieve good visible light transmittance, reduce rigidity, and process The effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

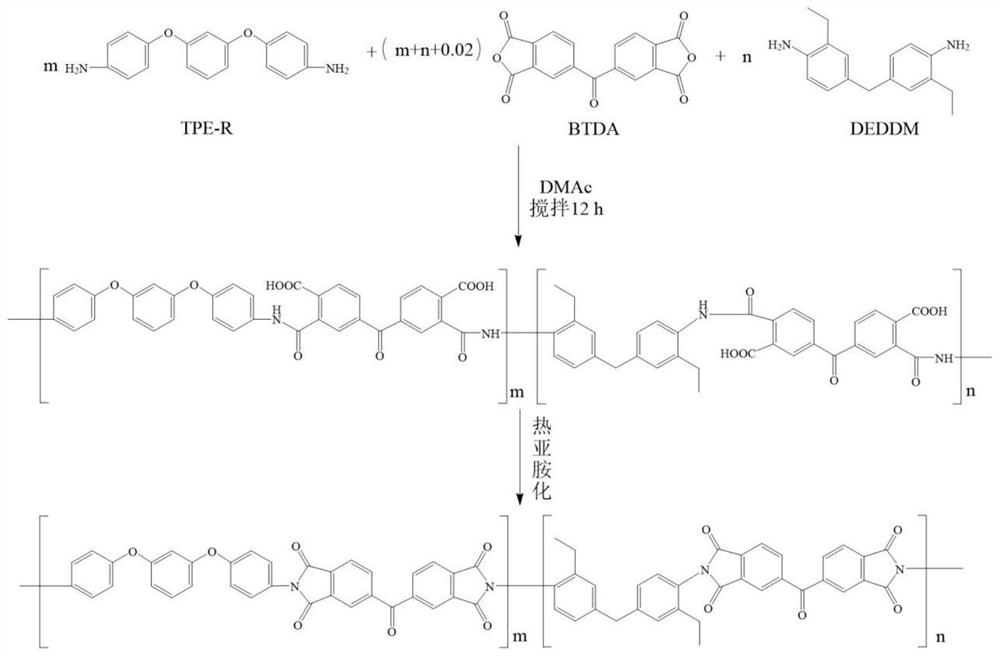

[0034] Embodiment 1 A kind of preparation method of polyimide film with low glass transition temperature

[0035] 1) Clean all the glass instruments to be used in the experiment and dry them for later use. At room temperature (25°C), add 3,3′-diethyl -4,4'-diaminodiphenylmethane (0.4070g, 1.6mmol), 1,3-bis(4'-aminophenoxy)benzene (0.1170g, 0.4mmol) and 3.5443g N,N-dimethyl base acetamide, magnetic sub-stir until completely dissolved, to obtain a mixed solution;

[0036] 2) Add 3,3',4,4'-benzophenone tetracarboxylic dianhydride (0.6575g, 2.04mmol) to the mixed solution obtained in step 1), the solid content is 25% (solid content is m DEDDM+TPE-R+BTDA / m DEDDM+TPE-R+BTDA+DMAc ) was stirred and dissolved, and reacted at room temperature for 12h to obtain polyamic acid glue;

[0037] 3) Drop the polyamic acid glue liquid obtained in step 2) on a clean glass plate, apply it evenly with a spatula, and heat imidize it through programmed temperature rise. ; 10°C / min to 120°C, vacu...

Embodiment 2

[0038] Embodiment 2 A kind of preparation method of polyimide film with low glass transition temperature

[0039]1) Clean all the glass instruments to be used in the experiment and dry them for later use. At room temperature (25°C), add 3,3′-diethyl -4,4'-diaminodiphenylmethane (0.3053g, 1.2mmol), 1,3-bis(4'-aminophenoxy)benzene (0.2340g, 0.8mmol) and 3.5904g N,N-dimethyl base acetamide, magnetic sub-stir until completely dissolved, to obtain a mixed solution;

[0040] 2) Add 3,3',4,4'-benzophenone tetracarboxylic dianhydride (0.6575g, 2.04mmol) to the mixed solution obtained in step 1), the solid content is 25% (solid content is m DEDDM+TPE-R+BTDA / m DEDDM+TPE-R+BTDA+DMAc ) was stirred and dissolved, and reacted at room temperature for 12h to obtain polyamic acid glue;

[0041] 3) Drop the polyamic acid glue liquid obtained in step 2) on a clean glass plate, apply it evenly with a spatula, and heat imidize it through programmed temperature rise. ; 10°C / min to 120°C, vacuu...

Embodiment 3

[0042] Embodiment 3 A kind of preparation method of polyimide film with low glass transition temperature

[0043] 1) Clean all the glass instruments to be used in the experiment and dry them for later use. At room temperature (25°C), add 3,3′-diethyl -4,4'-diaminodiphenylmethane (0.2544g, 1mmol), 1,3-bis(4'-aminophenoxy)benzene (0.2924g, 1mmol) and 3.6129g N,N-dimethylethyl Amide, stirred with a magnet until completely dissolved to obtain a mixed solution;

[0044] 2) Add 3,3',4,4'-benzophenone tetracarboxylic dianhydride (0.6575g, 2.04mmol) to the mixed solution obtained in step 1), the solid content is 25% (solid content is m DEDDM+TPE-R+BTDA / m DEDDM+TPE-R+BTDA+DMAc ) was stirred and dissolved, and reacted at room temperature for 12h to obtain polyamic acid glue;

[0045] 3) Drop the polyamic acid glue liquid obtained in step 2) on a clean glass plate, apply it evenly with a spatula, and heat imidize it through programmed temperature rise. ; 10°C / min to 120°C, vacuum in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com