Environment-friendly water-resistant wallpaper and preparation method thereof

A wallpaper and environmental protection technology, applied in the field of decorative materials, can solve the problems of difficult to meet the requirements of wallpaper strength, easy leakage, loose paper, etc., to achieve the effect of enhancing interaction force, improving strength and water resistance, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

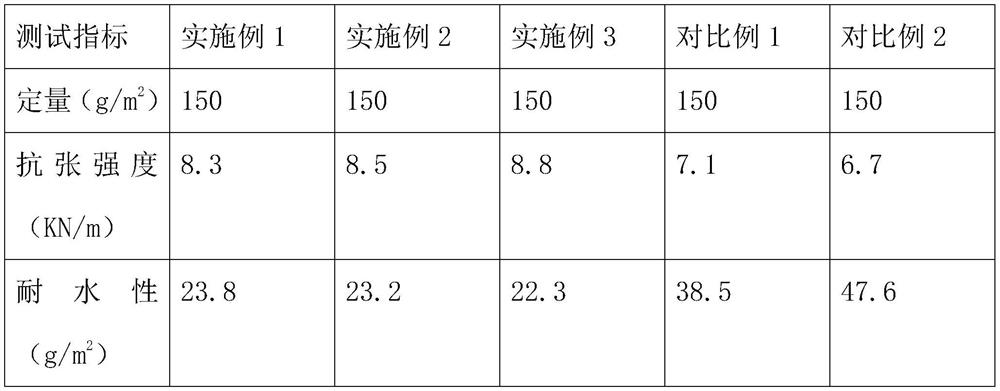

Examples

Embodiment 1

[0026] An environmentally friendly and water-resistant wallpaper, which is made by coating or spraying a surface treatment agent on the surface of a base paper and drying it;

[0027] The base paper includes the following raw materials in parts by mass: 15 parts of carambola wood pulp with a beating degree of 25°SR, 15 parts of bamboo pulp with a beating degree of 20°SR, 50 parts of softwood pulp with a beating degree of 20°SR, calcium carbonate 10 parts, 1 part of sizing agent AKD;

[0028] The surface treatment agent includes the following raw materials in parts by mass: 1 part of nanocellulose, 1 part of stearic acid, 3 parts of silane coupling agent KH550, 80 parts of absolute ethanol; wherein, the diameter of nanocellulose is 10-20nm, the length 1-3μm;

[0029] The preparation method of surface treatment agent comprises the steps:

[0030] (1) Add stearic acid into absolute ethanol to fully dissolve, then add nanocellulose to ultrasonically disperse evenly, heat and rea...

Embodiment 2

[0036] An environmentally friendly and water-resistant wallpaper, which is made by coating or spraying a surface treatment agent on the surface of a base paper and drying it;

[0037] The base paper includes the following raw materials in parts by mass: 25 parts of carambola wood pulp with a beating degree of 35° SR, 25 parts of bamboo pulp with a beating degree of 25° SR, 70 parts of softwood pulp with a beating degree of 25° SR, calcium carbonate 20 parts, 2 parts of sizing agent AKD;

[0038] The surface treatment agent includes the following raw materials in parts by mass: 2 parts of nanocellulose, 2 parts of stearic acid, 6 parts of silane coupling agent KH550, 120 parts of absolute ethanol; wherein, the diameter of nanocellulose is 10-20nm, the length 1-3μm;

[0039] The preparation method of surface treatment agent comprises the steps:

[0040] (1) Add stearic acid into absolute ethanol to fully dissolve, then add nanocellulose to ultrasonically disperse evenly, heat ...

Embodiment 3

[0046] An environmentally friendly and water-resistant wallpaper, which is made by coating or spraying a surface treatment agent on the surface of a base paper and drying it;

[0047] The base paper includes the following raw materials in parts by mass: 20 parts of carambola wood pulp with a beating degree of 32 ° SR, 20 parts of bamboo pulp with a beating degree of 22 ° SR, 60 parts of softwood pulp with a beating degree of 24 ° SR, calcium carbonate 15 parts, 1.5 parts of sizing agent AKD;

[0048] The surface treatment agent includes the following raw materials in parts by mass: 1.5 parts of nanocellulose, 1.5 parts of stearic acid, 5 parts of silane coupling agent KH550, and 100 parts of absolute ethanol; wherein, the diameter of nanocellulose is 10-20nm, and the length 1-3μm;

[0049] The preparation method of surface treatment agent comprises the steps:

[0050] (1) Add stearic acid into absolute ethanol to fully dissolve, then add nanocellulose to ultrasonically dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com