Preparation method of abalone shell powder/ZnO composite material doped intelligent hydrogel wound dressing with bacteriostatic effect

A composite material and antibacterial technology are applied in the field of smart hydrogel wound dressings and their preparation, which can solve problems such as side effects and achieve the effects of good biocompatibility, convenient operation and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

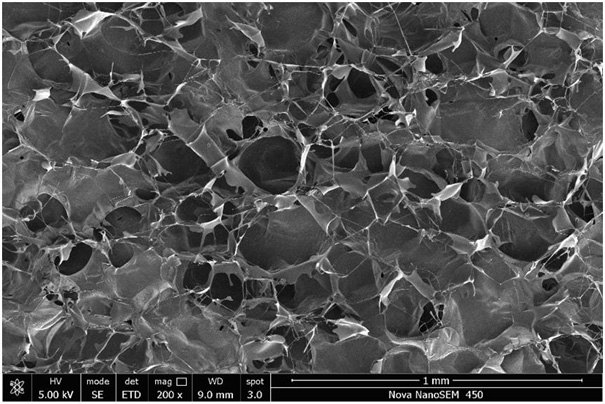

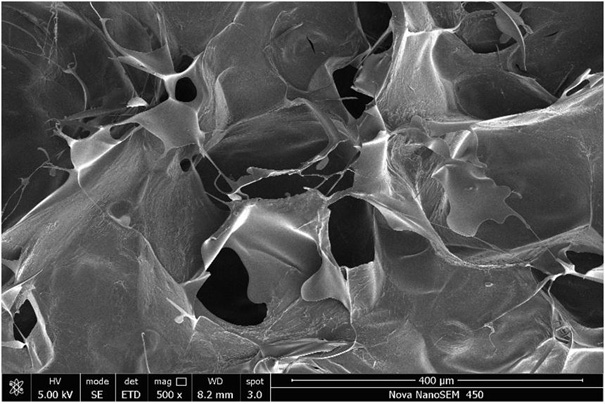

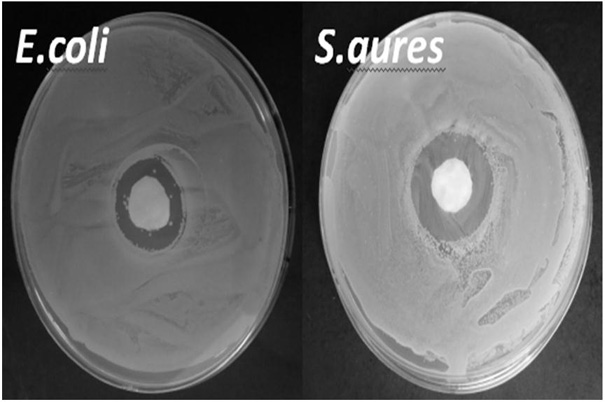

Image

Examples

Embodiment 1

[0053] A preparation method of an intelligent hydrogel wound dressing doped with antibacterial abalone shell powder / ZnO composite material, comprising the following steps:

[0054] (1) Wash the abalone shell with tap water and soak it in 8% sodium hydroxide solution for 1 hour, then wash it with distilled water;

[0055] (2) Dry the abalone shell obtained in step (1) in a blast drying oven at 100°C for 24 hours;

[0056] (3) Put the abalone shell obtained in step (2) into a multi-functional pulverizer, and pass through a 100-mesh sieve;

[0057] (4) Grinding the abalone shell powder obtained in step (3) with a planetary ball mill for 48 hours, then placing it in a muffle furnace at 1100°C for calcination for 2 hours, and grinding in a mortar to obtain the abalone shell powder carrier;

[0058] (5) Weigh 29.7g of zinc nitrate hexahydrate into a three-neck flask, add 100ml of distilled water to dissolve under the condition of constant temperature stirring at 90°C;

[0059] (6)...

Embodiment 2

[0068] A preparation method of an intelligent hydrogel wound dressing doped with antibacterial abalone shell powder / ZnO composite material, comprising the following steps:

[0069] (1) Wash the abalone shell with tap water and soak it in 8% sodium hydroxide solution for 1 h, then wash it with distilled water;

[0070] (2) Dry the abalone shells obtained in step (1) in a blast drying oven at 100 °C for 24 h;

[0071] (3) Put the abalone shell obtained in step (2) into a multi-functional pulverizer, and pass through a 100-mesh sieve;

[0072] (4) The abalone shell powder obtained in step (3) was ball-milled with a planetary ball mill for 48 h, then placed in a muffle furnace at 1100 °C for 2 h, and ground in a mortar to obtain the abalone shell powder carrier;

[0073] (5) Weigh 29.7 g of zinc nitrate hexahydrate into a three-necked flask, and add 100 ml of distilled water to dissolve under constant temperature stirring at 90 °C;

[0074] (6) Weigh 4.0 g of sodium hydroxide an...

Embodiment 3

[0083] A preparation method of an intelligent hydrogel wound dressing doped with antibacterial abalone shell powder / ZnO composite material, comprising the following steps:

[0084] (1) Wash the abalone shell with tap water and soak it in 8% sodium hydroxide solution for 1 hour, then wash it with distilled water;

[0085] (2) Dry the abalone shell obtained in step (1) in a blast drying oven at 100°C for 24 hours;

[0086] (3) Put the abalone shell obtained in step (2) into a multi-functional pulverizer, and pass through a 100-mesh sieve;

[0087] (4) Grinding the abalone shell powder obtained in step (3) with a planetary ball mill for 48 hours, then placing it in a muffle furnace at 1100°C for calcination for 2 hours, and grinding in a mortar to obtain the abalone shell powder carrier;

[0088] (5) Weigh 29.7g of zinc nitrate hexahydrate into a three-neck flask, add 100ml of distilled water to dissolve under the condition of constant temperature stirring at 90°C;

[0089] (6)...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap