Preparation method of MXene aerogel with spherical pore structure

A pore structure and airgel technology, applied in chemical instruments and methods, nanotechnology for materials and surface science, inorganic chemistry, etc., can solve the problems of lower overall performance, increased contact resistance, and lower specific surface area of materials. Achieve the effect of improving the overall performance, light density, and easy process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

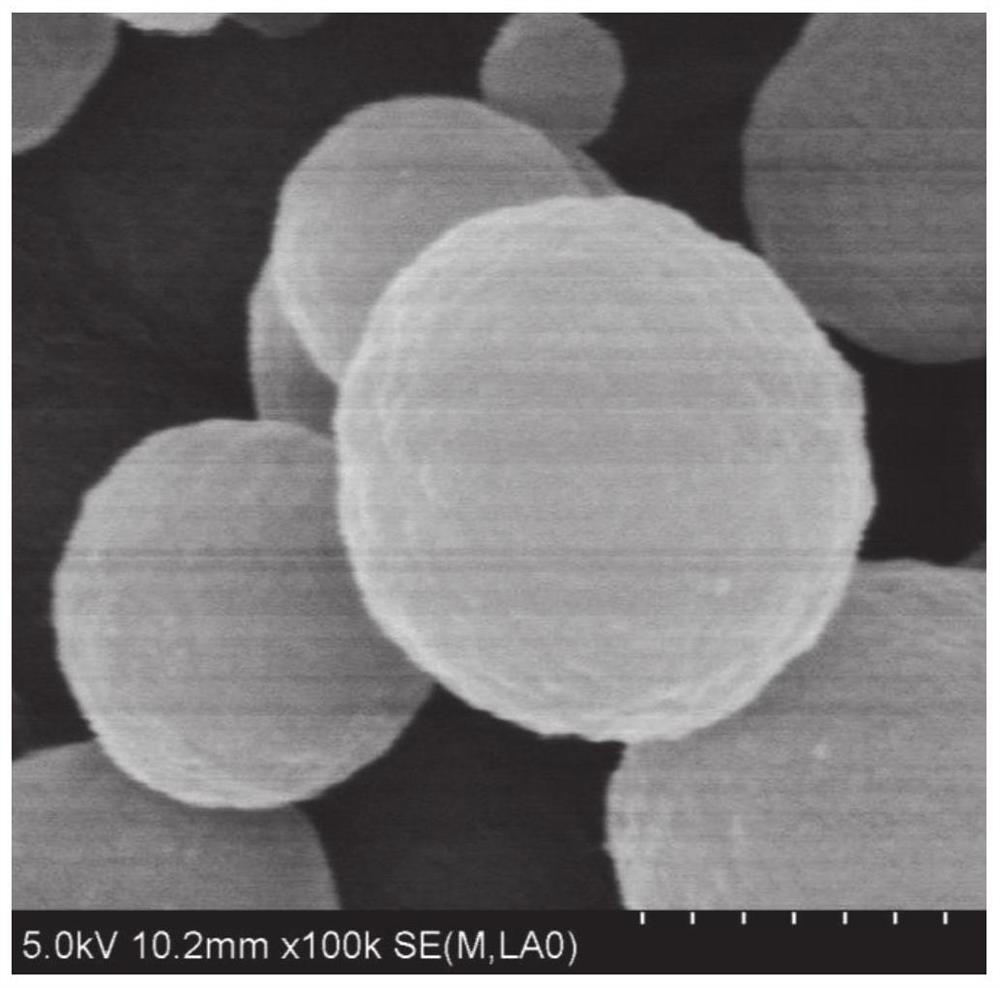

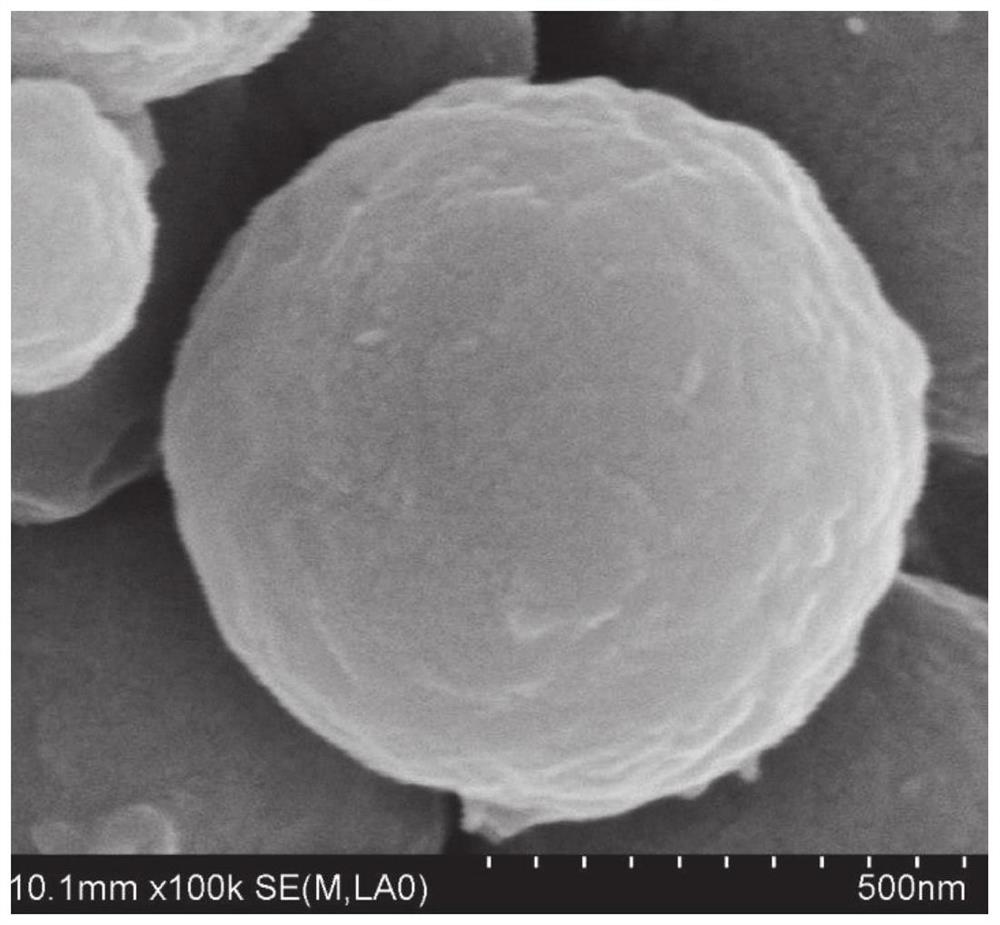

[0027] (1) Using a separatory funnel, wash 50 mL of styrene with 10% NaOH solution three to four times, and then with deionized water until the effluent is neutral, and store the pretreated styrene monomer in a refrigerator for later use.

[0028] (2) Put the styrene monomer obtained in (1) into a 250mL three-necked flask, and weigh 0.272g of azobisisobutyronitrile and 0.272g of methacryloxyethyltrimethylammonium chloride with an analytical balance , Measure 5mL of deionized water and 145mL of methanol with a graduated cylinder, and mix them with styrene.

[0029] (3) Put the three-neck flask in (2) into a water bath, stir with a magnetic force at 350 rpm, and pass argon gas for 30 minutes to remove oxygen.

[0030] (4) The reactants in (3) were kept at a water bath temperature of 80° C. to continue the reaction for 6 h.

[0031] (5) the reaction product in (4) was washed 3 times with methanol centrifugally, and deionized water was centrifugally washed 2 times to carry out so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com