A method for removing tetracycline antibiotics and heavy metal ions in livestock and poultry breeding wastewater

A technology for livestock and poultry breeding wastewater and heavy metal ions, applied in chemical instruments and methods, animal husbandry wastewater treatment, water pollutants, etc., can solve the problems of human life and ecological environment hazards, heavy metal and antibiotic complex pollution treatment, etc. Achieve the effects of promoting promotion and application, improving the efficiency of free radical formation, and obvious removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

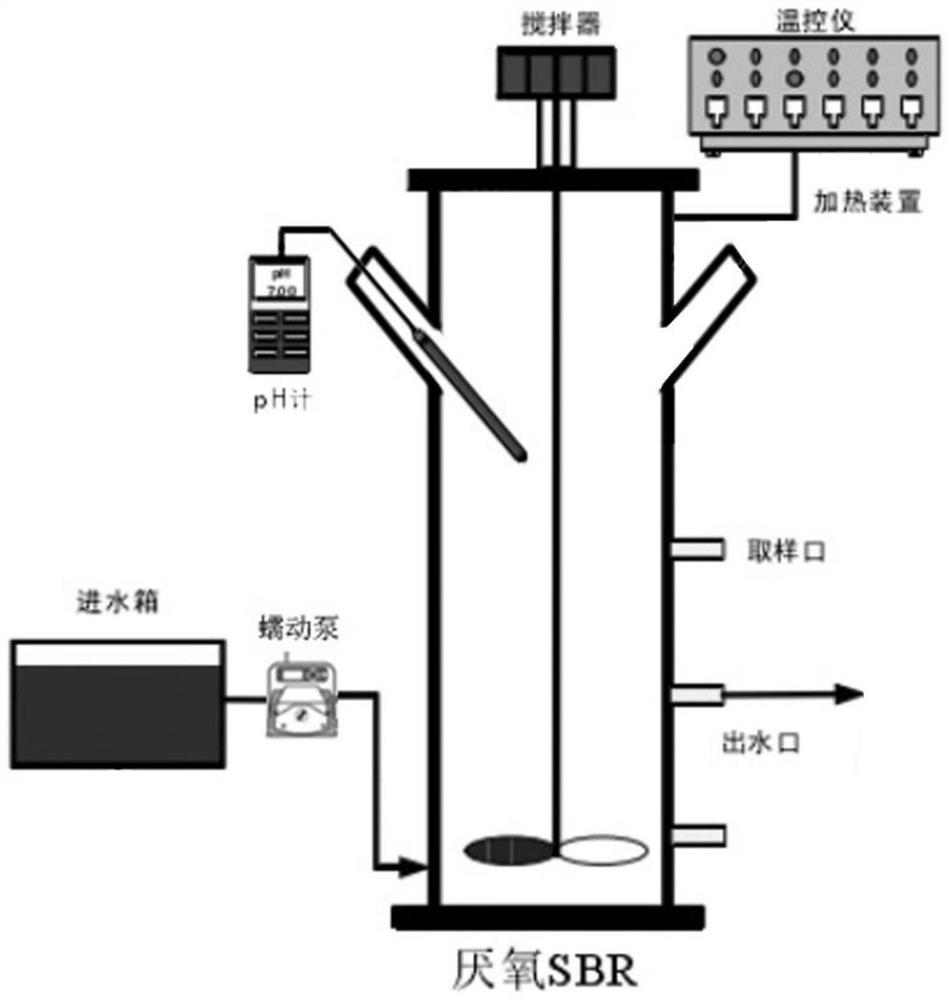

[0030] Xiang Ru figure 1 In the shown anaerobic sequencing batch reactor (ASBR), 10L of livestock and poultry wastewater (tetracycline concentration is 1mg / L; Zn 2+ The concentration is 5mg / L), and then immediately add 5g of sodium peroxodisulfate and peracetic acid, and the advanced oxidation reaction stage is 8h. After the temperature is equal to the temperature of the water bath (ie: 35°C), pump the sulfate-reducing bacteria culture solution that has been sterilized by high temperature and high pressure into the anaerobic sequencing batch reactor (ASBR), adjust the pH of the solution to 7.5, and pass in nitrogen After 15 minutes, sulfate-reducing bacteria were inoculated into the ASBR solution, and the dissimilation and reduction stage of sulfate-reducing bacteria was maintained for 10 days.

[0031] The nutrients required for the culture of sulfate-reducing bacteria include: magnesium chloride (MgCl 2 ) 2.0g, sodium citrate 5.0g, calcium sulfate (CaSO 4 2H 2 O) 1.0g, a...

Embodiment 2

[0034] Pump 10L of high temperature and high pressure sterilized livestock and poultry wastewater into the anaerobic sequencing batch reactor (ASBR) (the concentration of oxytetracycline is 1mg / L; the concentration of Fe(II) is 5mg / L), and then immediately add Each 5g of sodium peroxodisulfate and peracetic acid, the advanced oxidation reaction stage is 8h. After the temperature is equal to the temperature of the water bath (ie: 30°C), pump the sulfate-reducing bacteria culture solution that has been sterilized by high temperature and high pressure into the anaerobic sequencing batch reactor (ASBR), adjust the pH of the solution to 7.2, and pass in nitrogen After 20 minutes, sulfate-reducing bacteria were inoculated into the ASBR solution, and the dissimilation and reduction stage of sulfate-reducing bacteria was maintained for 12 days. The nutrients required for the culture of sulfate-reducing bacteria include: magnesium chloride (MgCl 2 ) 2.0g, sodium citrate 5.0g, calcium ...

Embodiment 3

[0037] Pump 10L of livestock and poultry wastewater that has been sterilized by high temperature and high pressure into the anaerobic sequencing batch reactor (ASBR) (the concentration of aureomycin is 1mg / L; the concentration of Pb(II) is 5mg / L), and then immediately add Each 5g of sodium peroxodisulfate and peracetic acid, the advanced oxidation reaction stage is 8h. After the temperature is equal to the temperature of the water bath (ie: 35°C), pump the sulfate-reducing bacteria culture solution that has been sterilized by high temperature and high pressure into the anaerobic sequencing batch reactor (ASBR), adjust the pH of the solution to 7.5, and pass in nitrogen After 10 minutes, sulfate-reducing bacteria were inoculated into the ASBR solution, and the dissimilation and reduction stage of sulfate-reducing bacteria was maintained for 15 days.

[0038] The nutrients required for the culture of sulfate-reducing bacteria include: magnesium chloride (MgCl 2 ) 2.0g, sodium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com