Full-automatic fiber material cutting process

A fiber material, fully automatic technology, applied in the direction of manufacturing tools, glass manufacturing equipment, etc., can solve the problems of slowing down the cutting efficiency of glass fiber materials, low degree of automation, low yield rate, etc., to improve cutting efficiency and effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

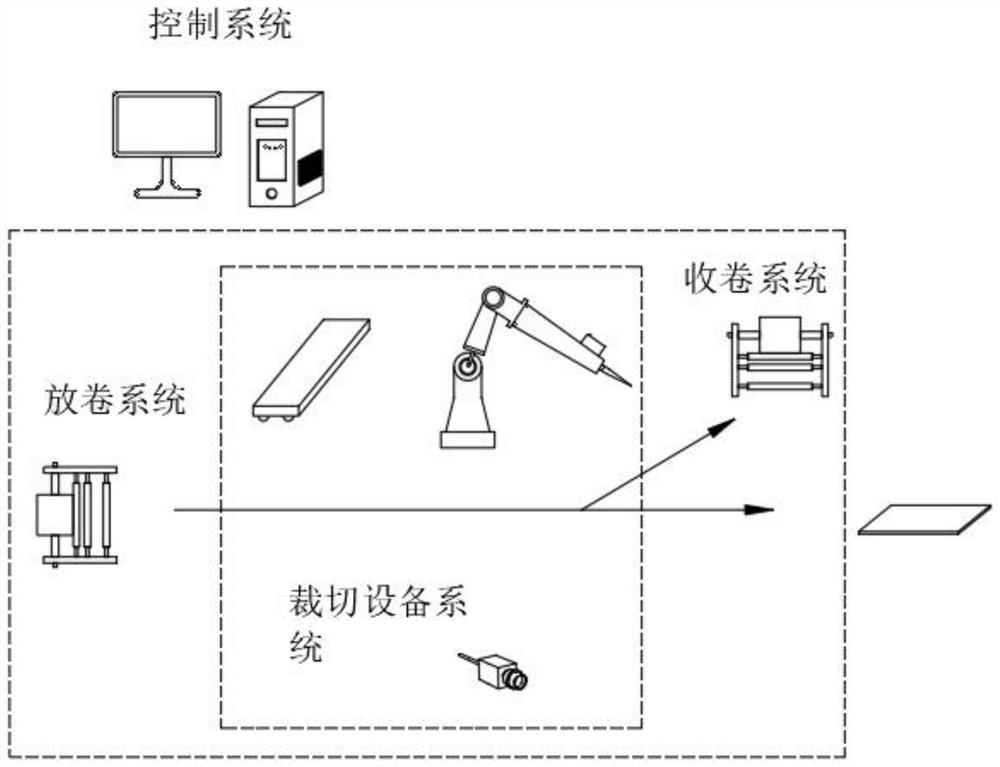

[0049] see figure 1 , a fully automatic fiber material cutting process, comprising the following steps:

[0050] S1. Input the cutting task into the control system in advance, and prepare the rolled glass fiber material;

[0051] S2. The rolled material is manually transported to the unwinding system equipment for automatic feeding, and the material is flattened into the cutting platform in the cutting equipment system;

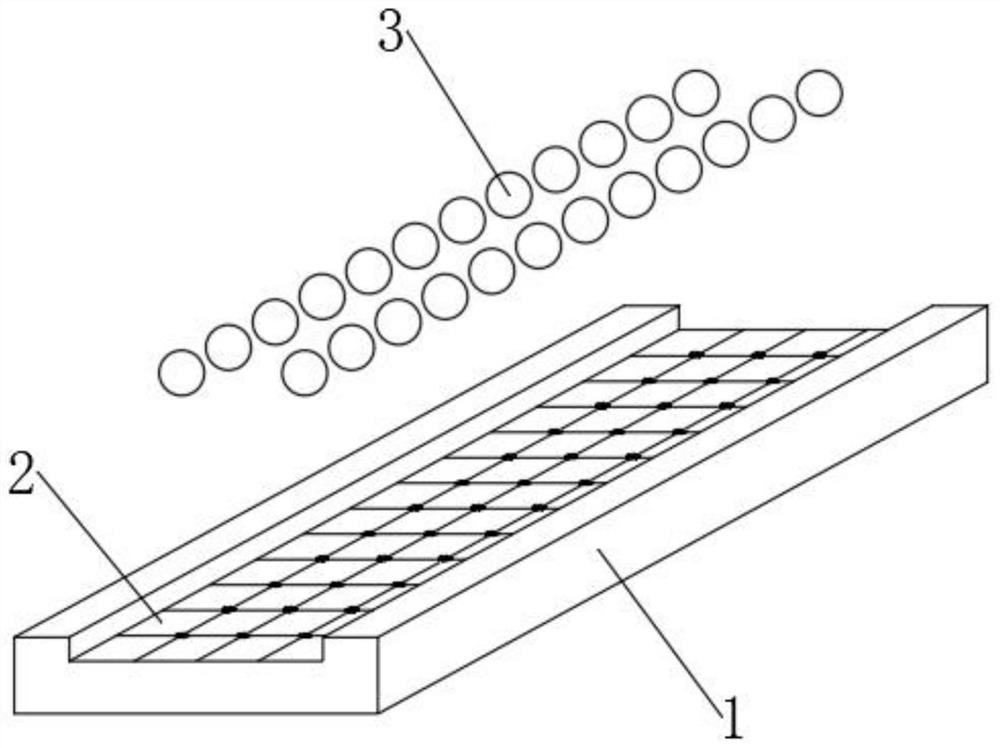

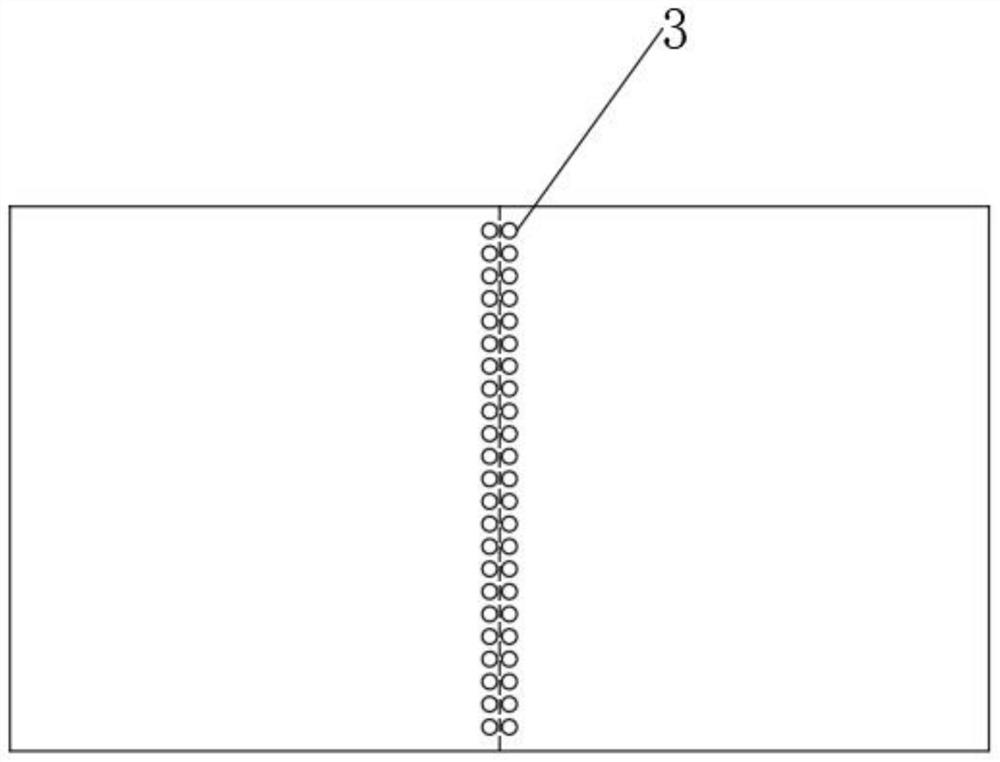

[0052] S3. In the cutting equipment system, the positioning device is firstly adjusted independently according to the cutting path in the cutting task through the pressing positioning device, and then the glass fiber material on the cutting platform is positioned;

[0053] S4. The cutting robot realizes the automatic cutting of raw materials along the cutting path according to the positioning of the pressing positioning device, and meets the cutting size and precision;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com