Synthesis and refining method of sodium methallyl sulfonate

A technology of sodium methacrylate and its refining method, which is applied in the direction of sulfonate preparation, chemical instruments and methods, organic chemical methods, etc., and can solve problems affecting product quality and batch-to-batch stability, difficulty in transferring solid materials, washing Low efficiency and other problems, to achieve the effect of uniform crystal growth, reduced energy consumption, and less washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

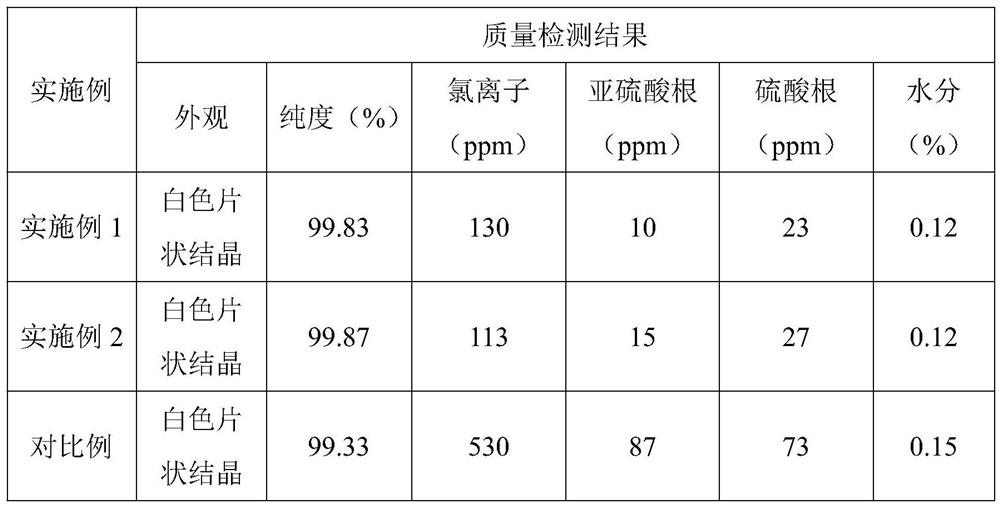

Examples

Embodiment 1

[0028] According to this embodiment, sodium methacrylate is prepared through the following steps:

[0029] (1), sulfonation reaction: Add 1.5kg of sodium sulfite solution with a mass fraction of 25% in a 2.5L reactor, heat up to 45°C after nitrogen replacement, start to add 264g of methallyl chloride dropwise, and the whole dropwise addition process Continue for 1 hour, rely on the reaction itself to exotherm, raise the temperature to 60-70°C, and keep the temperature for 3 hours; after the reaction, cool down to 40°C, put in 88g of solid sodium sulfite, stir and dissolve, then heat up to 45°C, add methallyl chloride dropwise 65g, the whole dropping process lasts 0.5h, relying on the heat release of the reaction itself and the heating of the heat conduction oil, the temperature is raised to 60-70°C, and after 2h of heat preservation reaction, the unreacted methallyl chloride is removed under the pressure of -0.95MPa , to obtain a sulfonation reaction solution. The whole react...

Embodiment 2

[0035] According to this embodiment, sodium methacrylate is prepared through the following steps:

[0036](1), sulfonation reaction: add 1.5kg of sodium sulfite solution with a mass fraction of 20% in a 2.5L reactor, heat up to 45°C after nitrogen replacement, start to add 211g of methallyl chloride dropwise, and the whole dropwise addition process Continue for 1 hour, rely on the reaction itself to exotherm, raise the temperature to 60-70°C, and keep the temperature for 3 hours; after the reaction, cool down to 40°C, put in 171g of solid sodium sulfite, stir and dissolve, heat up to 45°C, add methallyl chloride dropwise 127g, the whole dropping process lasts for 0.5h, relying on the heat release of the reaction itself and the heating of the heat transfer oil, the temperature is raised to 60-70°C, and after 2h of heat preservation reaction, the unreacted methallyl chloride is removed under the pressure of -0.95MPa , to obtain a sulfonation reaction solution. The whole reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com