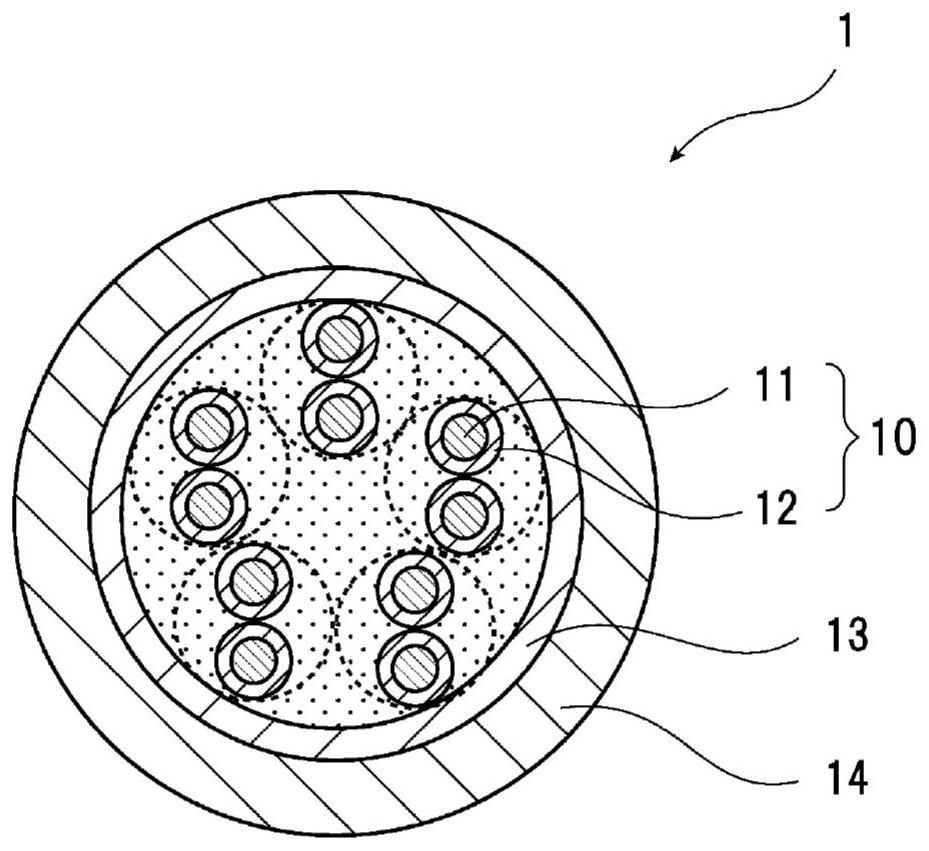

Cable and electric wire

A cable and conductor technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of cable breakage and low recovery of the outer skin.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

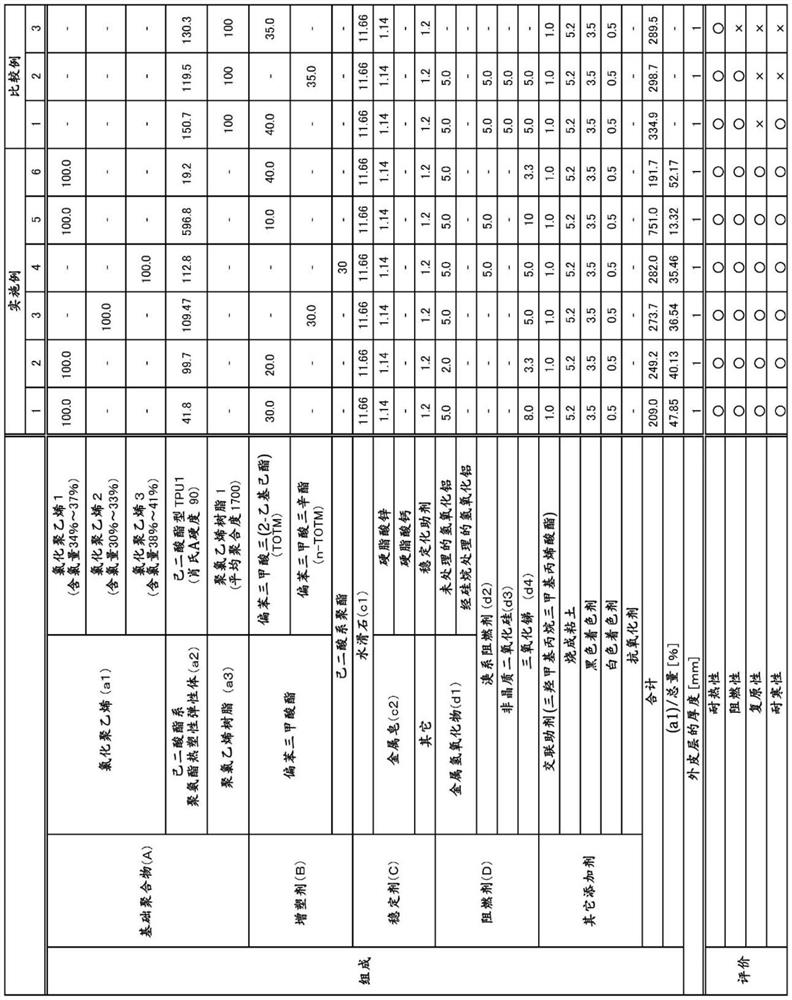

[0170] First, a conductor, a resin composition for forming an insulating layer, and a flame-retardant resin composition for forming a skin layer are prepared.

[0171] As the conductor, a 28AWG (19 / 0.08) TA conductor was used.

[0172] As the resin composition for forming the insulating layer, a composition containing ETFE (tetrafluoroethylene-ethylene copolymer) as a fluororesin was used.

[0173]The flame-retardant resin composition for forming the skin layer was prepared by mixing and kneading the above-mentioned materials so as to have the composition shown in Table 1 below. Specifically, 100 parts by mass of chlorinated polyethylene 1 and 41.8 parts by mass of adipate-type TPU1 as the base polymer (A), 30.0 parts by mass of TOTM as the plasticizer (B), and as the stabilizer (C 11.66 parts by mass of hydrotalcite (c1), 1.14 parts by mass of zinc stearate as metal soap (c2), 1.2 parts by mass of stabilizing aid, 5.0 parts by mass of flame retardant (D) belonging to metal h...

Embodiment 2~6

[0178] In Examples 2-6, as shown in Table 1, except having changed the kind and compounding quantity of (A) component - (D) component suitably, it carried out similarly to Example 1, and produced the cable.

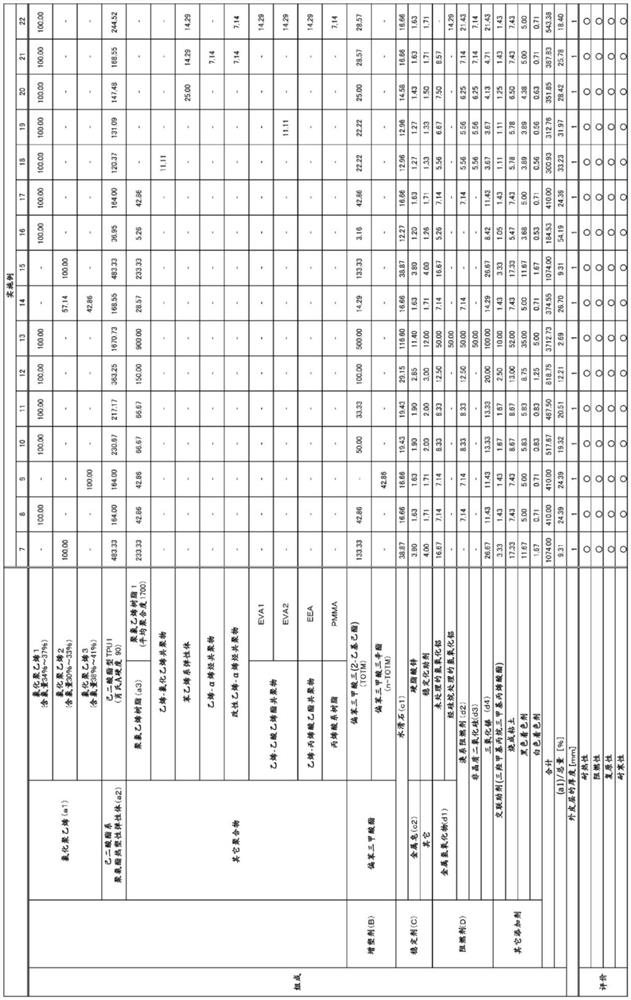

Embodiment 7~17

[0182] In Examples 7 to 17, as shown in the following Table 2, chlorinated polyethylene (a1), adipate-based TPU (a2) and polyvinyl chloride resin (a3) were used, and the content of each component was appropriately changed. Except for this, a cable was produced in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com