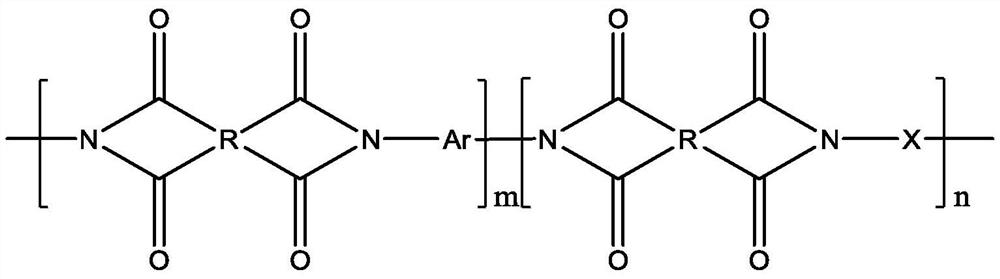

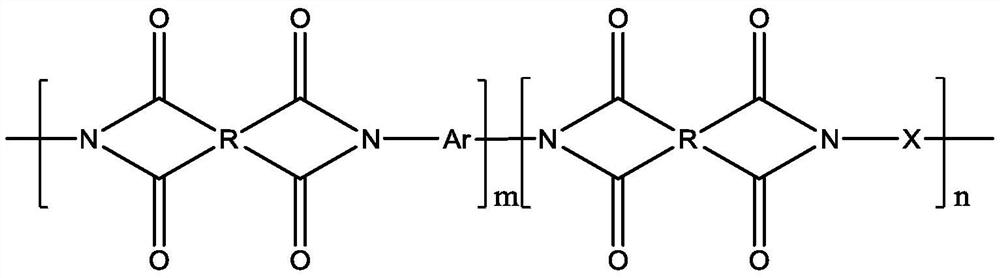

Soluble poly (siloxane-co-imide) block copolymer film and preparation and application thereof

A technology of block copolymer and siloxane diamine is applied in the field of preparation of soluble polyblock copolymer film, which can solve the problems of inability to make a self-supporting film, low gas permeability selectivity, difficulty in ultra-thinning, etc. The effect of low, good permeability and strong solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A 100ml dry four-neck flask equipped with a mechanical stirrer, a thermometer, a nitrogen inlet and a water separator was placed in a constant temperature water bath. At room temperature, add 50ml of N-methylpyrrolidone under nitrogen protection, add 1.222g of 2,6-diaminotoluene (0.011mol) under mechanical stirring, stir until completely dissolved, then add dropwise amodimethicone ( Molecular weight 2500) 5.000g (0.002 mol), after all dissolved, add bisphenol A dianhydride 6.763g (0.013 mol) in three times. React at 20°C for 4-24 hours to obtain a polyamic acid solution; then add 6.636 g (0.065 moles) of acetic anhydride and 6.577 g (0.065 moles) of triethylamine for chemical imidization, and react for 10-24 hours at room temperature to polymerize The product was settled in anhydrous methanol, washed three times with anhydrous methanol, air-dried at room temperature for 1 hour, and then dried in a vacuum oven at 100-250°C for 24-48 hours to remove residual moisture and ...

Embodiment 2

[0039] A 100ml dry four-neck flask equipped with a mechanical stirrer, a thermometer, a nitrogen inlet and a water separator was placed in a constant temperature water bath. At room temperature, add 50 ml of N-methylpyrrolidone under nitrogen protection, add 1.667 g of 2,6-diaminotoluene (0.0136 moles) under mechanical stirring, stir until completely dissolved, then add dropwise amino-terminated polydimethylsiloxane ( Molecular weight 2500) 2.500g (0.001 mole), after all dissolved, add bisphenol A dianhydride 7.647g (0.0147 mole) in three times. React at 20°C for 4-24 hours to obtain a polyamic acid solution; then add 7.453 g (0.073 moles) of acetic anhydride and 7.387 g (0.073 moles) of triethylamine for chemical imidization, and react for 10-24 hours at room temperature to polymerize The product was settled in anhydrous methanol, washed three times with anhydrous methanol, air-dried at room temperature for 1 hour, and then dried in a vacuum oven at 100-250°C for 24-48 hours ...

Embodiment 3

[0043] A 100ml dry four-neck flask equipped with a mechanical stirrer, a thermometer, a nitrogen inlet and a water separator was placed in a constant temperature water bath. At room temperature, add 50 ml of N-methylpyrrolidone under nitrogen protection, add 1.875 g of 2,6-diaminotoluene (0.0154 moles) under mechanical stirring, stir until completely dissolved, then add dropwise amodimethicone ( Molecular weight 2500) 12.50g (0.005 mol), after all dissolved, add bisphenol A dianhydride 10.608g (0.0159 mol) in three times. React at 20°C for 4-24 hours to obtain a polyamic acid solution; then add 8.168g (0.08 moles) of acetic anhydride and 8.095g (0.08 moles) of triethylamine for chemical imidization, and react for 10-24 hours at room temperature to polymerize The product was settled in anhydrous methanol, washed three times with anhydrous methanol, air-dried at room temperature for 1 hour, and then dried in a vacuum oven at 100-250°C for 24-48 hours to remove residual moisture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com