Method for constructing hybrid catalyst and cascade degradation of organophosphorus nerve poison by fixing palladium and organophosphorus hydrolase by using COFs

A nerve agent and organophosphorus technology, applied in the field of nanomaterials, can solve the problems of inconsistent catalytic conditions, unstable recovery of ultrafine Pd nanoparticles and organophosphorus hydrolase, etc., and achieve the effect of complete degradation and reduced loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

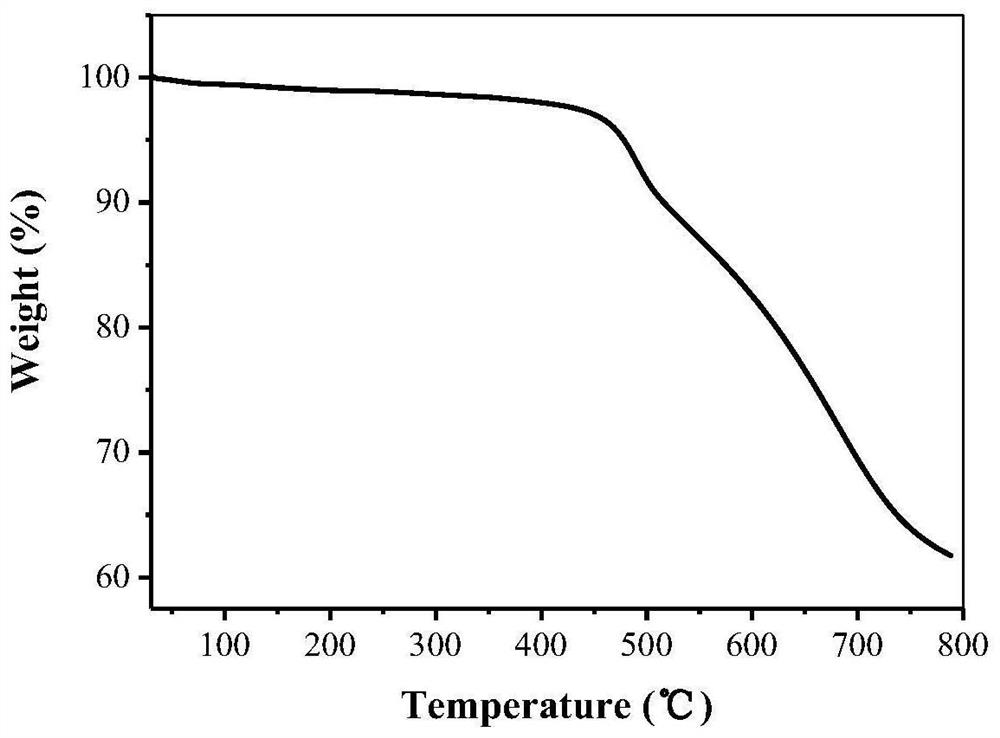

[0042] Example 1: Using COFs to immobilize palladium and organophosphate hydrolase to construct a hybrid catalyst, the preparation process is as follows:

[0043]

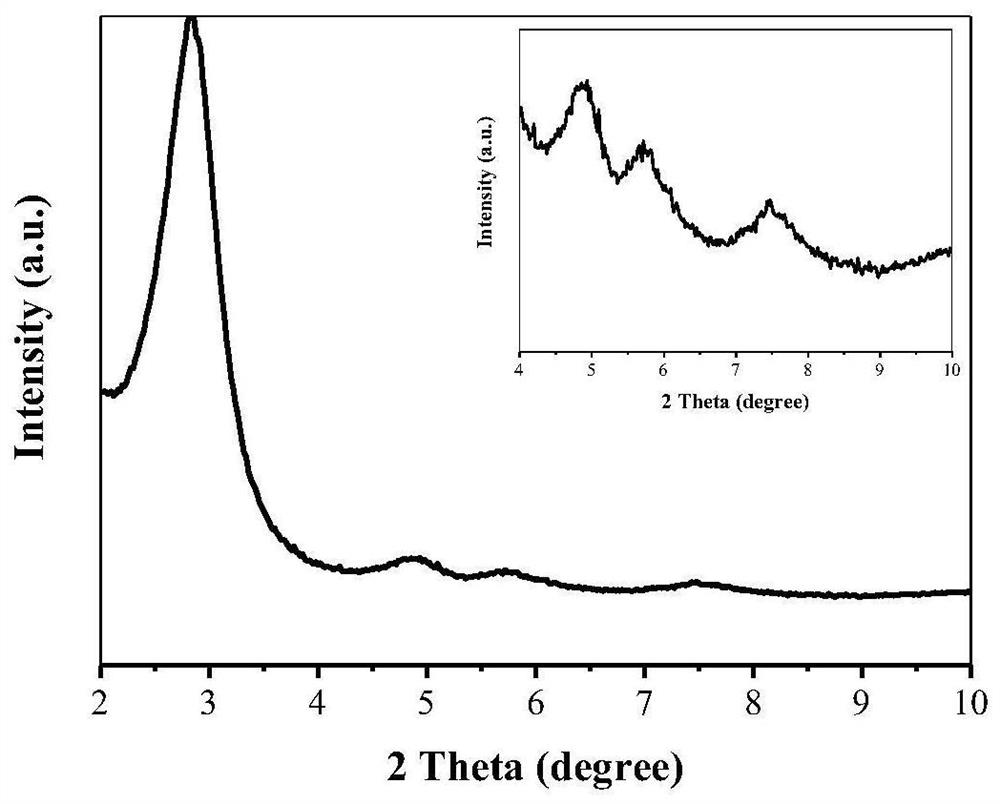

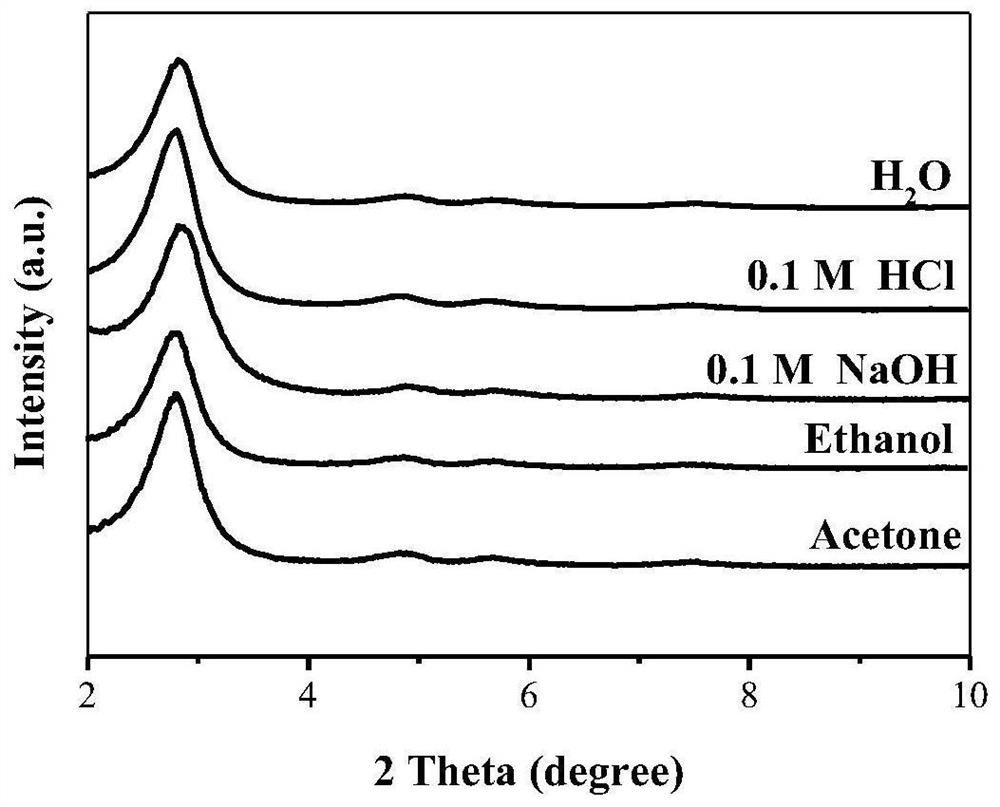

[0044] 1) Using a monomer with a triazine group and a monomer with a hydroxyl group, a covalent organic framework material COFs-OH containing a hydroxyl group is prepared by a hot solvent method; the specific process is:

[0045] 0.26mmol of 2,4,6-tris(4-aminophenyl)-1,3,5-triazine, 0.39mmol of 2,5-dihydroxyterephthalaldehyde, 5.1mL of mesitylene, 0.9 Add mL of dioxane and 0.6 mL (6mol / L) of acetic acid into the pressure-resistant tube, sonicate for 15 minutes to fully disperse the mixture, then vacuumize to remove the air, and then react in an oil pan at 120°C for 3 days. After completion, a reddish-brown precipitate is obtained; the reddish-brown solid is separated and purified, that is, first washed with dioxane three times, then washed with N,N-dimethylformamide until there is no turbidity, and finally washe...

Embodiment 2

[0056] Embodiment 2: Effect of reaction temperature and sodium borohydride addition on the activity of cascade degradation methyl parathion

[0057] Add 5 mg of the hybrid catalyst prepared in Example 1 (fixed for 8 h), 1.44 μmol of methyl parathion and a certain amount of sodium borohydride to 1.5 mL of Tris-HCl buffer (50 mM, pH=9) In the reaction at a certain temperature, the reaction temperature and the addition of sodium borohydride in the system were optimized by measuring the amount of 4-AP generated per unit time. When the sodium borohydride addition amount is 22.5 mg, the cascade degradation activity when the reaction temperature is 20 ° C, 30 ° C, 40 ° C, 50 ° C, 60 ° C, 70 ° C, 80 ° C and 90 ° C is as follows Figure 9 As shown, when the reaction temperature is 70°C, the highest degradation activity is 8.372μM / min / g. Taking the preferred reaction temperature of 70°C, the cascade degradation activity is as Figure 10 As shown, the degradation rate is the largest wh...

Embodiment 3

[0058] Example 3: 5 mg of the hybrid catalyst prepared in Example 1 (fixed time of 8 h), 1.44 μmol of methyl parathion and 18.75 mg of sodium borohydride were put into 1.5 mL of pH=9, and the concentration was 50 mM In Tris-HCl buffer, react at 70°C. By monitoring the content of 4-AP in the reaction system at different times of degradation to observe the degradation of organophosphorus nerve agents, from Figure 11 It can be observed that methyl parathion can be completely degraded to 4-AP in 50min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com