Unconventional uranium polymetallic ore mineral green separation method

A separation method and multi-metal technology, applied in centrifuges, grain processing, centrifuges with rotating drums, etc., can solve problems such as high production costs, restricted leaching rate, and leaching technology that cannot meet industrial needs. To achieve the effect of broad applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

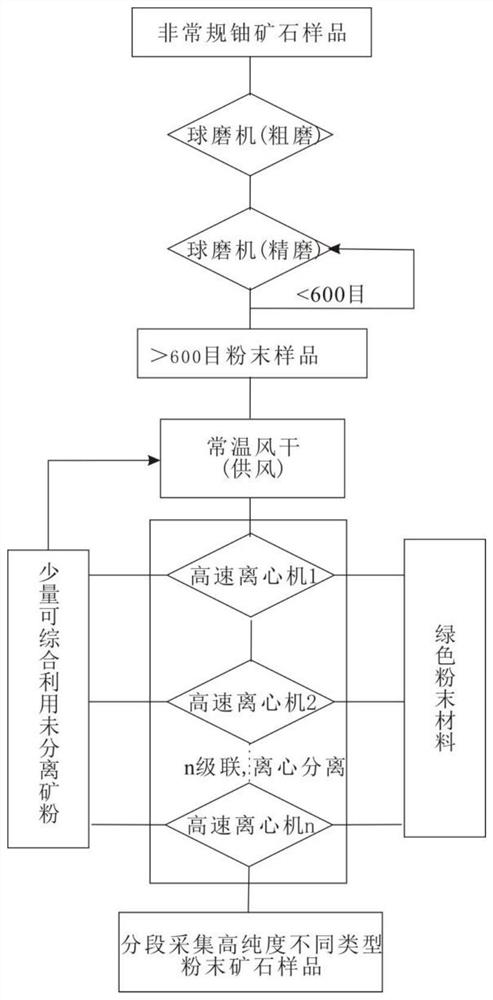

[0050]Such asfigure 1 As shown, the unconventional uranium multi-metal ore mineral green separation method of the present embodiment includes the following steps.

[0051](1) Preprocessing: Prepare unconjuguano ore samples, spare;

[0052](2) Raw milling: Select the unconventional uranium ore sample after pre-treatment, transfer to the ball mill to obtain a crude material;

[0053](3) Fabricating treatment: Select Step (2) The crude material after coarse milling, continuing fine grinding treatment in the ball mill, resulting in fine material;

[0054](4) Screening processing: Powder sample having a particle size greater than 600 mesh is screened from the fine material after refining treatment;

[0055](5) Dry treatment: Select Step (4) Screening the processed powder sample and transfer to the wind dryer for normal temperature drying;

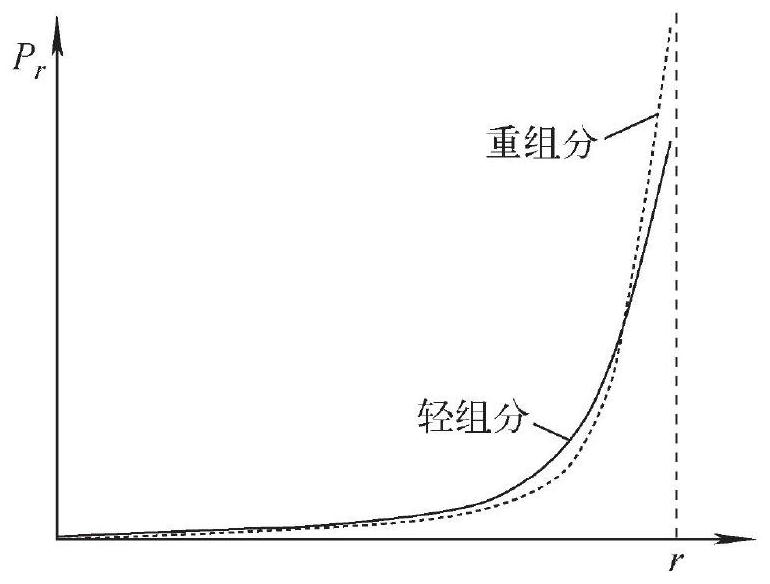

[0056](6) Multi-stage parallel centrifugation: Select Step (5) The powder sample after air-dried processed, transferred to a multi-stage parallel high-speed centrifuge...

Embodiment 2

[0098]This embodiment lacks fine grinding processing with respect to Embodiment 1, including the following steps.

[0099](1) Preprocessing: Prepare unconjuguano ore samples, spare;

[0100](2) Raw milling: Select the unconventional uranium ore sample after pre-treatment, transfer to the ball mill to obtain a crude material;

[0101](3) Dry treatment: Select Step (2) After screening the processed powder sample, transfer to the wind dryer for normal temperature drying;

[0102](4) Multi-stage parallel centrifugation: Select Step (3) The powder sample after air-drying, transferred to a multi-stage parallel high-speed centrifuge for centrifugation;

[0103](5) Recycling processing: Select a different level of centrifuge in the high-speed centrifuge in step (4), collect the target sample (segment collecting high purity different type powder ore samples).

[0104]In the separation method described above,

[0105]In step (1), unconjuguano ore samples are pre-pulverized.

[0106]In the separation method described...

Embodiment 3

[0124]This embodiment lacks air-drying processing with respect to Example 1, including the following steps.

[0125](1) Preprocessing: Prepare unconjuguano ore samples, spare;

[0126](2) Raw milling: Select the unconventional uranium ore sample after pre-treatment, transfer to the ball mill to obtain a crude material;

[0127](3) Fabricating treatment: Select Step (2) The crude material after coarse milling, continuing fine grinding treatment in the ball mill, resulting in fine material;

[0128](4) Screening processing: Powder sample having a particle size greater than 600 mesh is screened from the fine material after refining treatment;

[0129](5) Multi-stage parallel centrifugation: Select Step (4) Screening Processing Powdered Samples and transferred to a multi-stage parallel high-speed centrifuge for centrifugation;

[0130](6) Recycling processing: Select the different levels of the centrifuge in the high-speed centrifuge in step (4), collect the target sample (segmented high-purity different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com