Preparation method of lactide and reaction device

A technology of lactide and lactide stream, applied in the field of lactide, can solve the problems of poor removal effect, reduced yield, large equipment investment, etc., achieves outstanding economic advantages, reduces equipment investment and production Cost, effect of simplified process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

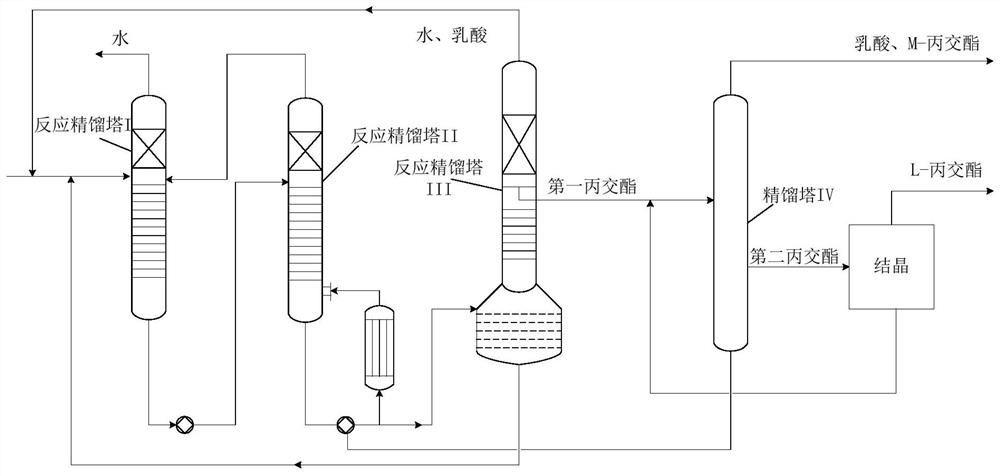

[0145] This embodiment provides a kind of preparation method of lactide, and the preparation method is specifically as follows:

[0146] (1) The following reactions are coupled to the reactive distillation tower I for: dehydration of lactic acid, preliminary polymerization of lactic acid, purification of water and hydrolysis of defocused oil;

[0147] (2) The following reaction is coupled to the reactive distillation column II: the first lactic acid oligomer obtained by the preliminary polymerization reaction is subjected to an oligomerization reaction to obtain a second lactic acid oligomer, and the second lactic acid oligomer is reduced The polymer undergoes a first depolymerization reaction;

[0148] (3) making the bottom liquid of the reactive distillation tower II enter the reactive distillation tower III, and carry out the second depolymerization reaction in the depolymerization reaction section of the reactive distillation tower III;

[0149] (4) The lactide obtained i...

Embodiment 2

[0161] This embodiment provides a lactide preparation method and reaction device, the reaction device is the same as in Example 1, the only difference is that the following operating conditions are different:

[0162] Operating conditions: The pressure of reactive distillation column I is normal pressure, the temperature at the top of the tower is 100°C, the temperature on the trays is controlled by heat transfer oil heat exchange tubes, the temperature of the upper 10 trays is 150-160°C, and the temperature of the lower 10 trays is The temperature is 160~170℃; the reflux ratio is 1:1. Reactive distillation column feed 20kg / h.

[0163] The pressure of the reactive distillation column II is 1kPaA, the temperature on the tray is controlled by heat transfer oil heat exchange tubes, and is controlled at 170°C from top to bottom, and the temperature of the reboiler in the tower kettle is 190°C.

[0164] Reaction result: the Mw of the lactic acid oligomer in the bottom liquid of th...

Embodiment 3

[0166] This embodiment provides a method for preparing lactide and a reaction device. The reaction device is the same as that in Embodiment 1, the only difference being that the temperature of the reboiler in the first depolymerization reaction section, that is, the reactive distillation column II, is controlled at 200°C.

[0167] Reaction result: the conversion rate of the first depolymerization reaction of the lactic acid oligomers in the reactive distillation column II is 10%. The yield of the second depolymerization reaction in the reactive distillation column III is 64.2%, the optical purity of crude lactide is 97.3%, the content of lactic acid is 0.46%, and the total content of 2-5 lactic acid polymerization products is 1.05%.

[0168]As can be seen from the above results, the step-by-step depolymerization method of the present invention can be used to regulate the lactic acid content of crude lactide, the content of lactic acid and lactic acid oligomers in the crude lact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com