a fe 2 o 3 Preparation method of /ag/ phenolic resin sandwich structure nanodisc

A phenolic resin and nanodisc technology, applied in nanotechnology and other directions, can solve the problems of rare nanodisc structure composite materials, and achieve the effects of easy implementation of control conditions and means, good reproducibility of product appearance, and stable structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a Fe 2 O 3 The preparation method of / Ag / phenolic resin sandwich structure nanodisks comprises the following steps:

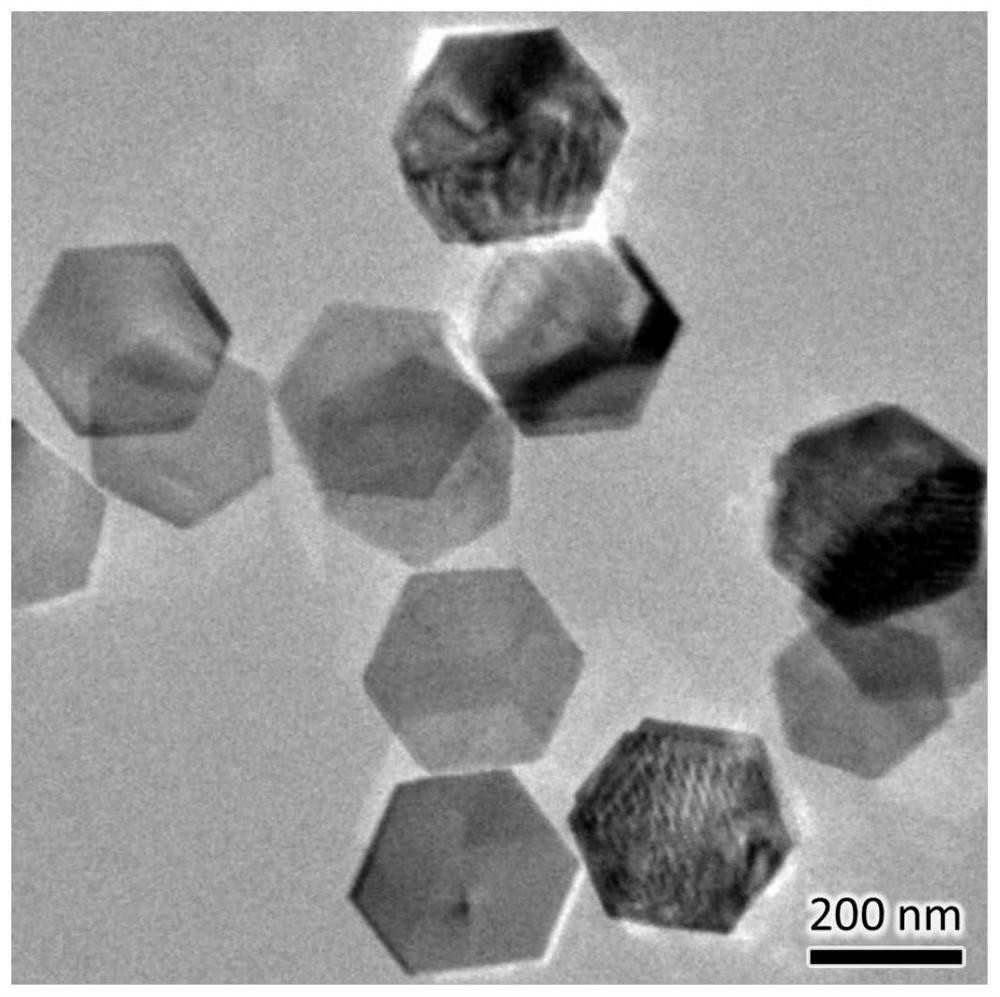

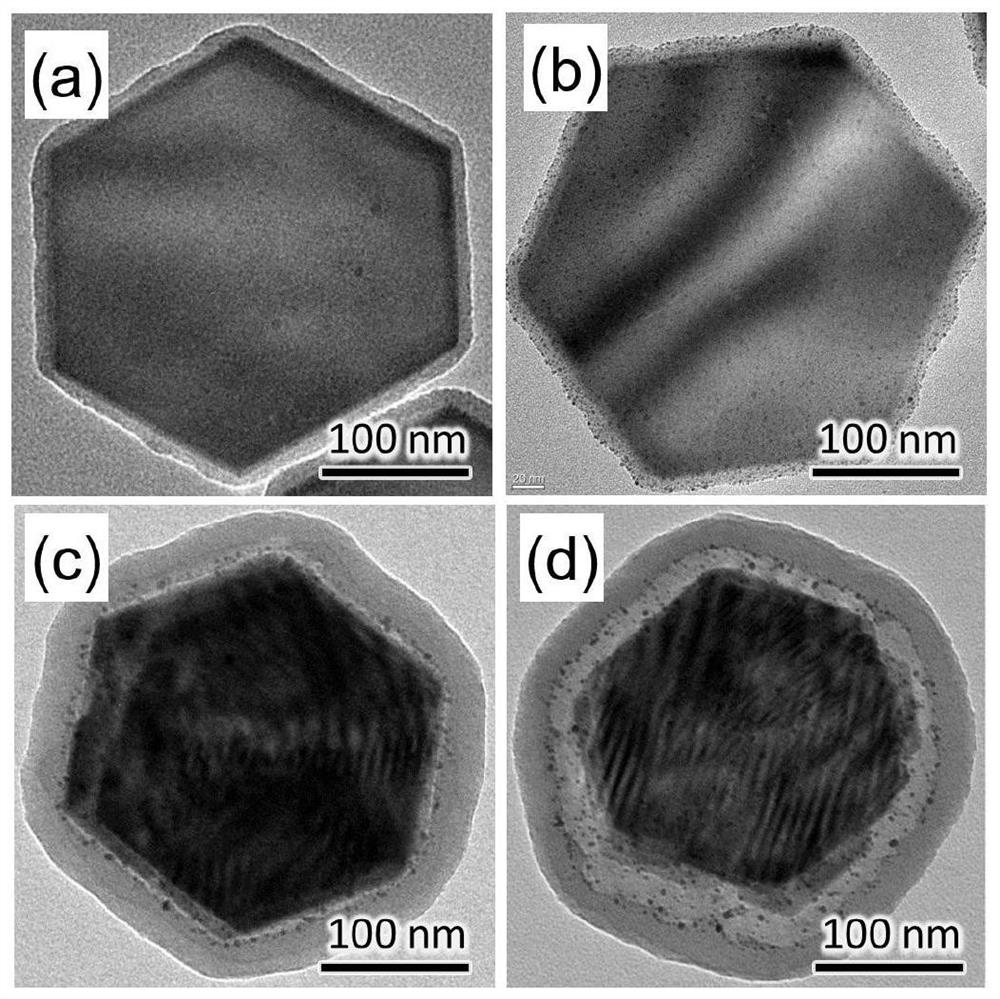

[0050] (1) Weigh 0.545g of ferric chloride hexahydrate, add 1.4mL of ultrapure water, 20mL of anhydrous ethanol, 2.5g of anhydrous sodium acetate, the above mixture is transferred to a 50mL stainless steel hydrothermal kettle, heated to 170°C and reacted for 12h and then separated washing. Add 90mL ultrapure water and 10mL polyacrylic acid aqueous solution (M W =1800, 7.2 mg / mL), stirred with a magnetic sub for 24 h, centrifuged and washed, and dispersed in 30 mL of ultrapure water (about 5 mg / mL). figure 1 Fe obtained for Example 1 2 O 3 TEM image of nanodisks, Fe 2 O 3 The side length of the nanodisk is 150 nm.

[0051] (2) Take 25mg Fe 2 O 3 Add 3 mL of ultrapure water, 20 mL of absolute ethanol, 1 mL of ammonia water, and 50 μL of ethyl orthosilicate to react at room temperature for 30 min at room temperature, and w...

Embodiment 2

[0057] This embodiment provides a Fe 2 O 3 The preparation method of / Ag / phenolic resin sandwich structure nanodisks comprises the following steps:

[0058] (1) Weigh 0.545g of ferric chloride hexahydrate, add 1.4mL of ultrapure water, 20mL of anhydrous ethanol, 2.5g of anhydrous sodium acetate, the above mixture is transferred to a 50mL stainless steel hydrothermal kettle, heated to 170°C and reacted for 12h and then separated washing. Add 90mL ultrapure water and 10mL polyacrylic acid aqueous solution (M W =1800, 7.2 mg / mL), stirred with a magnetic sub for 24 h, centrifuged and washed, and dispersed in 30 mL of ultrapure water (about 5 mg / mL). In this step, Fe surface-modified polyacrylic acid is obtained 2 O 3 Nanodisc.

[0059] (2) Take 25mg Fe 2 O 3 Add 3 mL of ultrapure water, 20 mL of absolute ethanol, 1 mL of ammonia water, and 50 μL of ethyl orthosilicate to react at room temperature for 30 min at room temperature, and wash with ethanol by centrifugation. Fe ...

Embodiment 3

[0065] This embodiment provides a Fe 2 O 3 The preparation method of / Ag / phenolic resin sandwich structure nanodisks comprises the following steps:

[0066] (1) Weigh 0.545g of ferric chloride hexahydrate, add 1.4mL of ultrapure water, 20mL of anhydrous ethanol, 2.5g of anhydrous sodium acetate, the above mixture is transferred to a 50mL stainless steel hydrothermal kettle, heated to 170°C and reacted for 12h and then separated washing. Add 90mL ultrapure water and 10mL polyacrylic acid aqueous solution (M W =1800, 7.2 mg / mL), stirred with a magnetic sub for 24 h, centrifuged and washed, and dispersed in 30 mL of ultrapure water (about 5 mg / mL). In this step, Fe surface-modified polyacrylic acid is obtained 2 O 3 Nanodisc.

[0067] (2) Take 25mg Fe 2 O 3 Add 3 mL of ultrapure water, 20 mL of absolute ethanol, 1 mL of ammonia water, and 50 μL of ethyl orthosilicate to react at room temperature for 30 min at room temperature, and wash with ethanol by centrifugation. Fe ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com