Device and method for recovering cadmium cotton through spin current electric field enhanced replacement

An electric field and cadmium sponge technology, which is applied in the field of devices for reinforced replacement and recovery of cadmium sponge by a spin current electric field, can solve the problems of low recovery rate, increased processes, and many residues, so as to eliminate concentration polarization, improve efficiency, and promote transmission. effects of qualitative processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

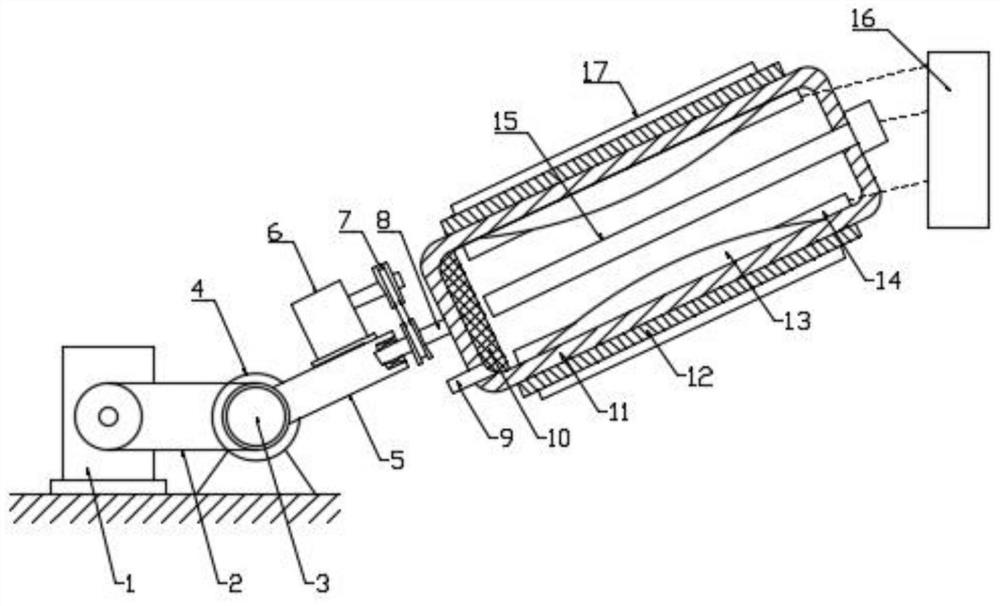

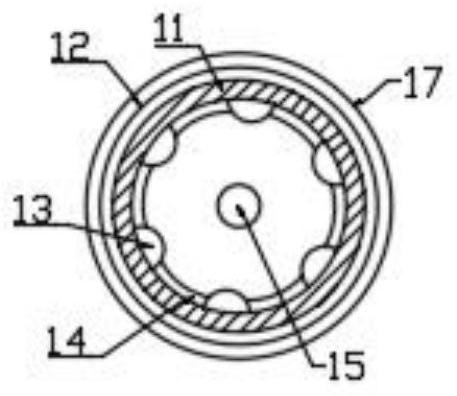

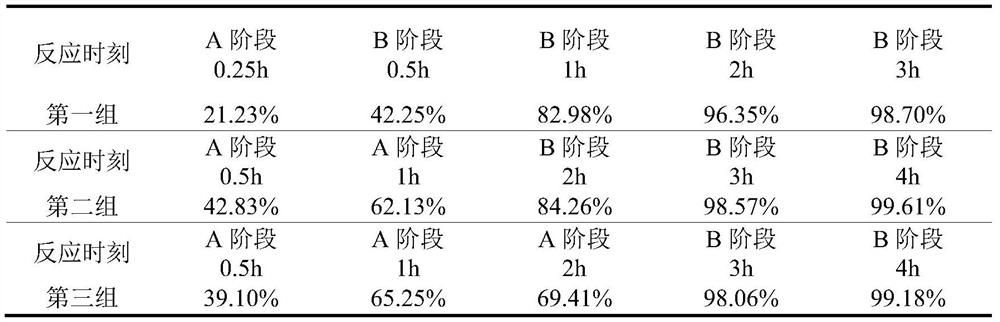

Embodiment 1

[0047] The original concentration of the raw material liquid is: Zn 4g / L, Cu 6g / L, pH=2. Take 4L of the cadmium-containing zinc sulfate solution containing 2g / L of cadmium and send it to the reaction tank, and use the heating device to raise the temperature of the solution to 60°C. Add dilute sulfuric acid to adjust the pH to 2. The purity of the zinc rod anode is 99%, and the size is φ4cm×30cm. The zinc rod anode is inserted and installed on the axis of the reaction tank. The aluminum-lined cathode is cylindrical, with an inner diameter of 12cm, a length of 30cm, a thickness of 0.5cm, and a purity of 95%. The distance between the zinc rod anode and the inner wall of the aluminum-lined cathode is 10cm. Rotate the reaction tank and keep it at a speed of 10r / min for a period of time as the reaction A stage. Turn on the switch, couple the electric field for the reaction system, and set the current density to 5mA / cm 2 . Continue to allow the reaction tank to spin for a period ...

Embodiment 2

[0051] Send 4L of a solution with an original concentration of Zn 4g / L and Cu 6g / L to the reaction tank, and use a heating device to raise the temperature of the solution to 60-65°C. The purity of the zinc rod anode is 99%, and the size is φ4cm×30cm. The aluminum-lined cathode is cylindrical, with an inner diameter of 12cm, a length of 30cm, a thickness of 0.5cm, and a purity of 95%. The distance between the zinc rod anode and the inner wall of the aluminum-lined cathode is 10cm. Add dilute sulfuric acid to adjust the pH value to 2, insert and install the zinc rod anode on the axis of the reaction tank. Make the reaction tank spin at a speed of 10r / min, turn on the switch after 30 minutes, couple the electric field for the reaction system, and set the current density to 10mA / cm 2 . Continue to allow the reaction tank to spin and react for 4 hours, then stop spinning, disconnect the coupling power supply and stop heating, and empty the zinc sulfate solution from the drain por...

Embodiment 3

[0055] Send 4L of cadmium-containing zinc sulfate solution containing 2g / L of cadmium to the reaction tank, and use a heating device to raise the temperature of the solution to 50-60°C. Add dilute sulfuric acid to adjust the pH value to 2, insert and install the zinc rod anode on the shaft reaction tank body core. Make the reaction tank spin at a speed of 10r / min, turn on the switch after 10 minutes to couple the electric field of the reaction system, and set the current density to 5mA / cm 2 . Continue to allow the reaction tank to spin and react for 5 hours, then stop spinning, disconnect the coupling power supply and stop heating, and empty the zinc sulfate solution from the drain port. Continue to let the reaction tank spin at a high speed of 60r / min for 10min, centrifuge and filter to obtain cadmium cotton, and the filtrate enters the drain port and collects it. Open the reaction tank, collect the cadmium cotton on the filter bottom net, and perform cake pressing.

[005...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com