Non-catalyzed double-reducing-agent NOx removal method and non-catalyzed double-reducing-agent NOx removal device

A reducing agent and removal technology, which is applied in the direction of exhaust device, silencer device, exhaust treatment device, etc., can solve the problems of solid deposit blockage, high catalyst cost, exhaust odor, etc., and achieve the state of reducing agent Stable, good exhaust gas/reductant mixture, NOX removal rate improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

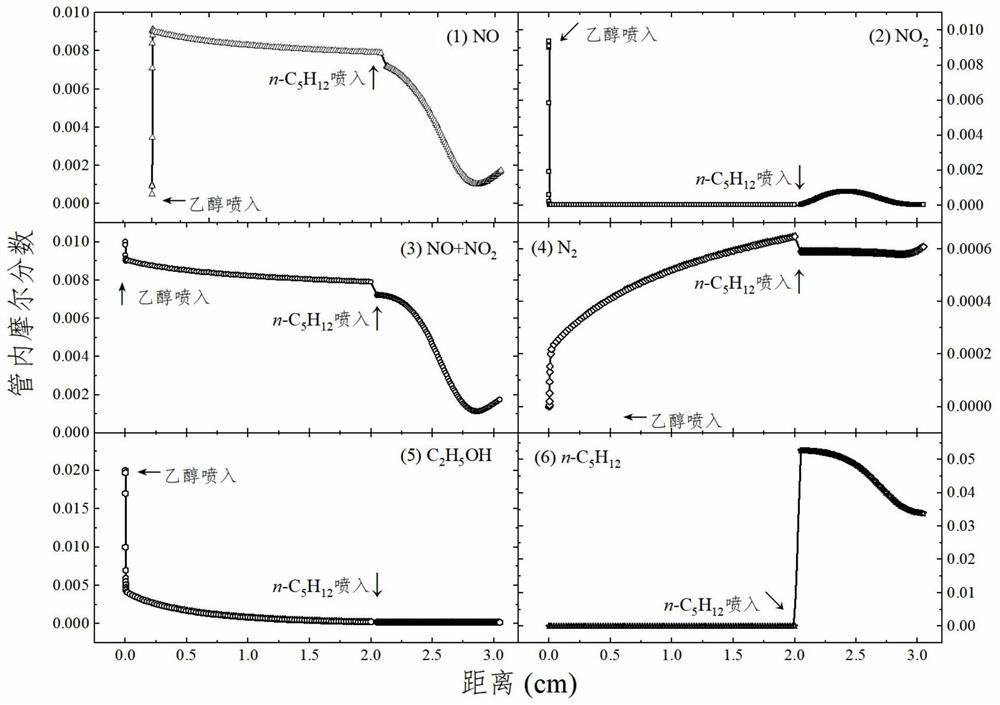

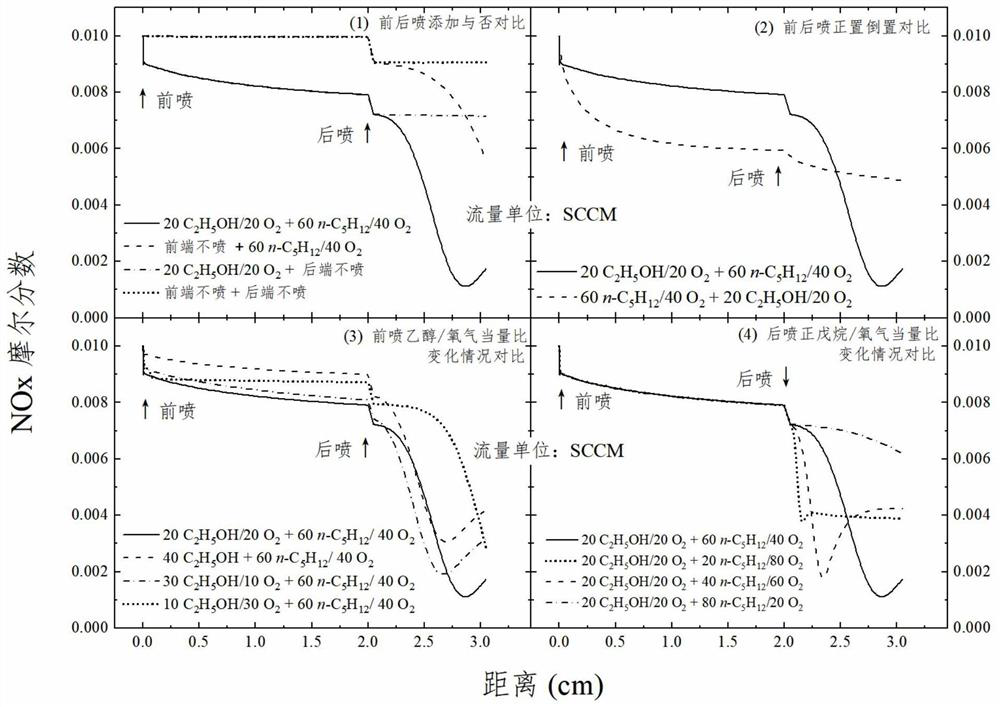

Embodiment 1

[0060]Double reducing agent NO without cataract of the present inventionXExample of removal method with ethanol C2Hide5OH and n-pentane CH3(CH2)3CH3Or N-C5Hide12As a front spray reducing agent and the post-spray reducing agent, cooperate with auxiliary gas oxygen O2Realize NOXRemove. After the above method is applied to the oxidation catalyst (DOC), the exhaust gas treated is not high on the NOx component, NO and NO2Effective removal can be achieved in a volume ratio of 1: 9, 3: 7, 1: 1, 7: 3, 9: 1;XThe effective application temperature of the removal strategy is 100 ~ 800 ° C, the maximum temperature can be adapted to reach 800 ~ 1000 ° C, which can be covered with current NH.3The operating temperature of the -SCR system and the diesel engine, the fans of the gasoline engine post-treatment device; the present invention NOXThe best applicable system in the removal method is about 100.0 kPa, and the effective application of the total pressure is 0.5 ~ 1.5ATM. The maximum total pressu...

Embodiment 2

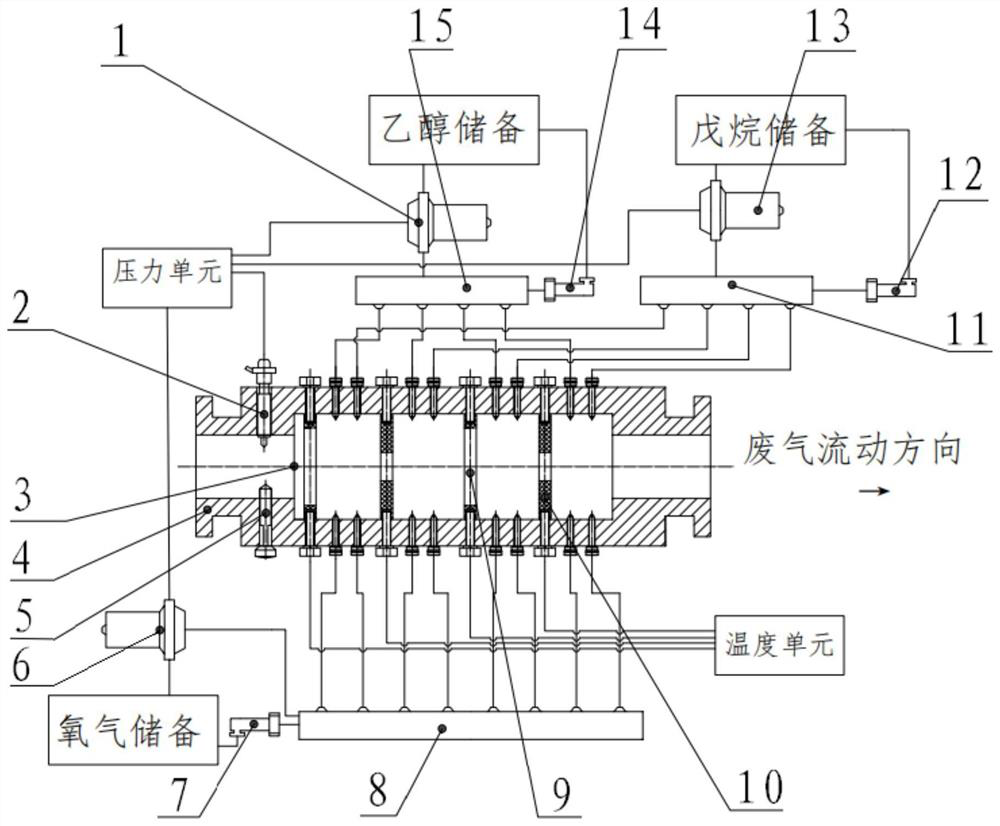

[0066]A non-catalytic dual reducing agent NO proposed by the present inventionXThe rear treatment device of the removal is designed as an example, such as the post-processing device design of 4 spray modules.image 3 ,Figure 4 ,Figure 5 As shown, there are four spray modules in the direction of the fluid outlet to the fluid outlet in the direction of the fluid exit to the fluid outlet direction.Figure 6As shown, it is recorded as the first stage spray module 41, the secondary spray module 42, the third-stage spray module 43 and the fourth stage spray module 43, and the tube wall of the tube body is provided in the front end of the first stage spray module 41. Pressure sensor 2 and exhaust gas-containing oxygen content sensor 5.

[0067]The structure of the four spray modules is the same, including the heating sheet 10 and the temperature sensor provided on the lumen of the tubular body 3 and four nozzles disposed on the tubular wall 4, such asFigure 5 As shown, the heating sheet 10 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com