Preparation method of environment-friendly novel sanitizer

An environmentally friendly, fungicide technology, applied in the direction of disinfectants, fungicides, botanical equipment and methods, etc., can solve the problems of poor spore killing effect and low virus effect, so as to achieve good promotion value and avoid Large dosage, strong killing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

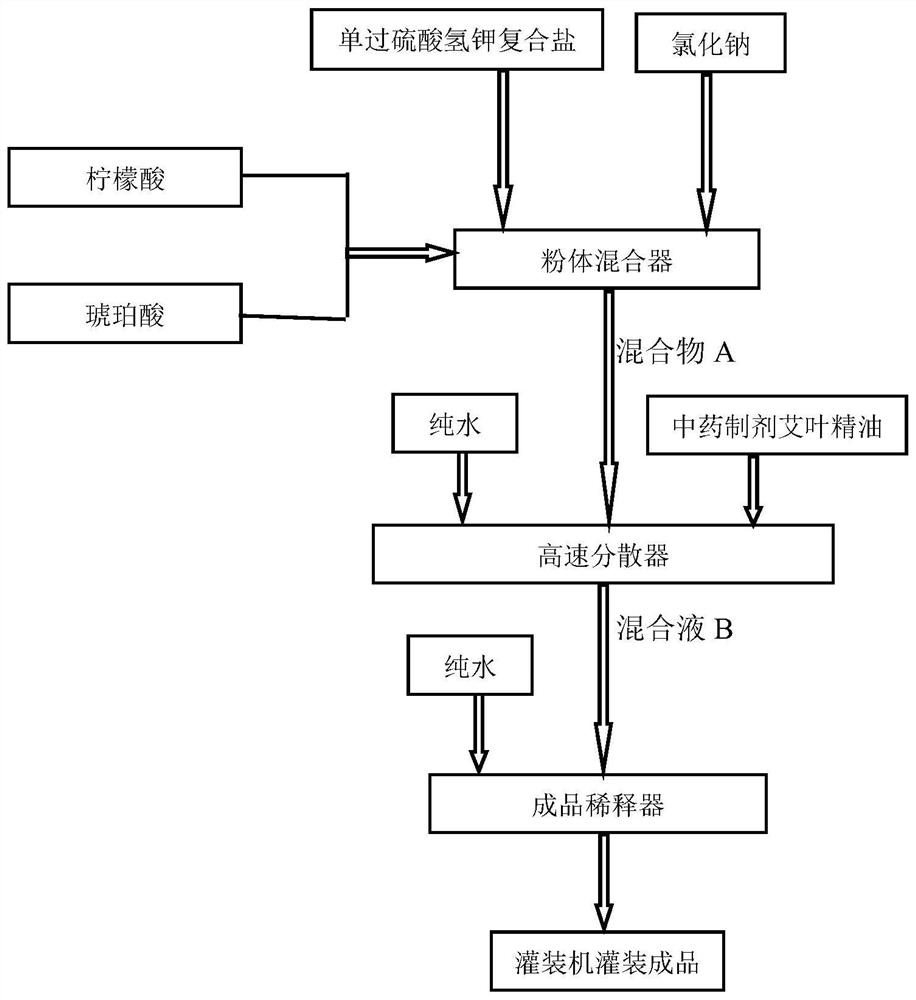

[0047] (1) Potassium monopersulfate compound salt powder and sodium chloride are mixed in a ratio of 25:1 to form a 50kg powder, then 5kg of citric acid and 2.5kg of succinic acid are placed in a powder mixer to fully mixed to form mixture A;

[0048] (2) Inject 600 kg of pure water into the high-speed disperser, and add mixture A while stirring under the condition of high-speed disperser rotating speed of 1000 rpm, and at the same time, slowly and uniformly add 5 kg of Chinese medicine preparation Artemisia argyi essential oil for about 25 minutes, mix A and Chinese medicine After adding all the preparations, turn the high-speed disperser at a high speed of 3000 rpm and stir for 60 minutes to fully and evenly disperse the components to form a thick mixed solution B.

[0049] (3) After stirring and diluting according to the volume ratio of the mixed solution B to pure water of 1:500, the finished product of the new liquid disinfectant and bactericide is made through a filling ...

Embodiment 2

[0055] (1) Mix potassium monopersulfate compound salt powder and sodium chloride in a ratio of 30:1 to form 60kg of powder, then put 5kg of citric acid and 2kg of succinic acid in a powder mixer and mix thoroughly , forming a mixture A;

[0056] (2) Pour 1000 kg of pure water into the high-speed disperser, and add mixture A while stirring under the condition of high-speed disperser rotating speed 800 rpm, and at the same time, slowly and uniformly add 6 kg of Chinese medicine preparation Artemisia argyi essential oil for about 30 minutes. Mixture A and Chinese medicine After adding all the preparations, turn the high-speed disperser at a high speed of 3500 rpm and stir for 70 minutes to fully and evenly disperse the components to prepare a thick mixed solution B.

[0057] (3) After stirring and diluting according to the volume ratio of the mixed solution B to pure water of 1:1000, the finished product of the new liquid disinfectant and bactericide is made through a filling mac...

Embodiment 3

[0061] (1) Mix potassium monopersulfate compound salt powder and sodium chloride at a ratio of 40:1 to form 60kg of powder, then place 6kg of citric acid and 3kg of succinic acid in a powder mixer and mix thoroughly , forming a mixture A;

[0062] (2) 800kg of pure water is injected into the high-speed disperser, and the mixture A is added while stirring under the condition of the speed of the high-speed disperser at 800 rpm, and 6kg of the traditional Chinese medicine preparation Artemisia argyi essential oil is slowly and uniformly added for about 30 minutes, and the mixture A and the traditional Chinese medicine After adding all the preparations, turn the high-speed disperser at a high speed of 3500 rpm and stir for 80 minutes to fully and evenly disperse the components to make a thick mixed solution B.

[0063] (3) After stirring and diluting according to the volume ratio of the mixed solution B to pure water of 1:800, the finished product of the new liquid disinfectant an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com