Sulfur reduction reaction catalytic material as well as preparation method and application thereof

A catalytic material and reaction technology, applied in carbon preparation/purification, electrochemical generator, secondary battery repair/maintenance, etc., can solve problems such as poor battery rate performance, improve electrode rate characteristics, and broad application space , the effect of improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] As another preferred embodiment of the present invention, the preparation method of the nano-metal oxide comprises the following steps:

[0032] The orthosilicate compound is mixed with the first solution, and ammonia water is added to react, and the precipitate is collected, washed and dried to obtain the nanometer metal oxide; wherein, the first solution is water and / or alcohol.

[0033] As another preferred embodiment of the present invention, in the preparation method of the nanometer metal oxide, the volume ratio of the orthosilicate compound to the first solution is 1:20-50.

[0034] Preferably, the volume ratio of the orthosilicate compound to the first solution is 1:30.

[0035] As another preferred embodiment of the present invention, in the preparation method of the nanometer metal oxide, the drying is at 40°C-90°C for 6-12 hours.

[0036] Preferably, the drying is performed in a drying oven at 60° C. for 10 hours.

[0037] As another preferred embodiment of...

Embodiment 1

[0071] A method for preparing a catalytic material for sulfur reduction reaction, comprising the following steps:

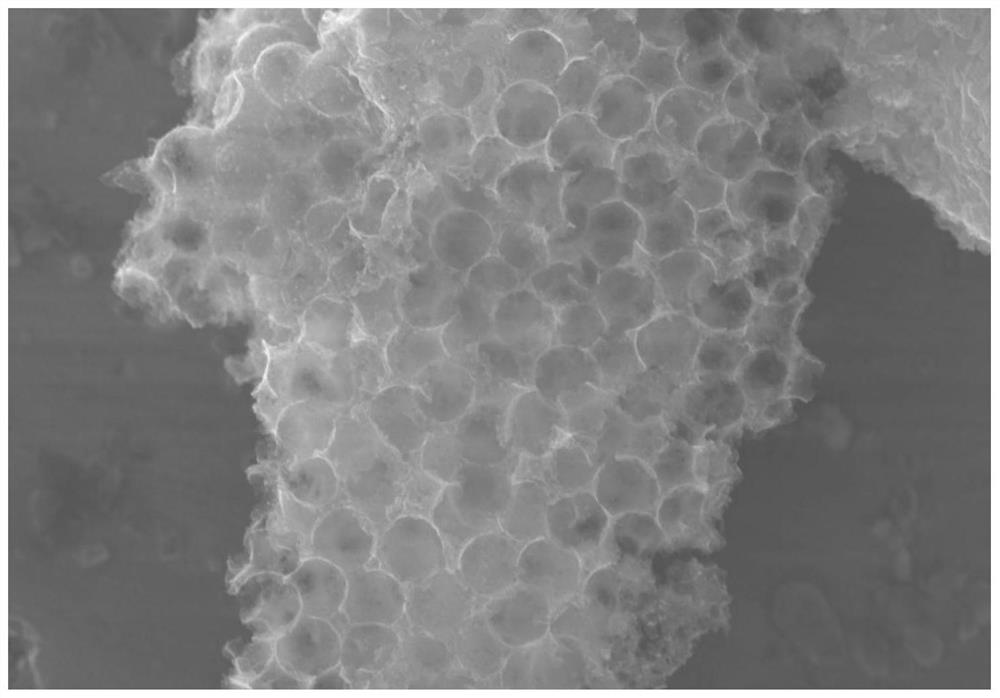

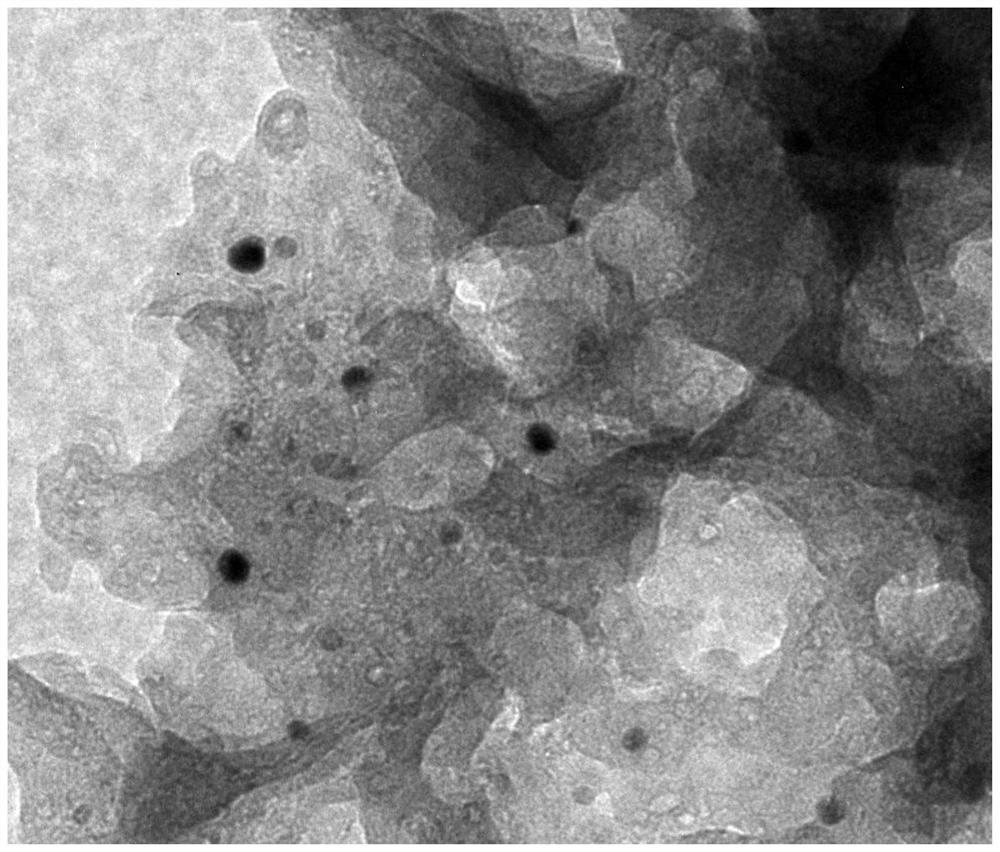

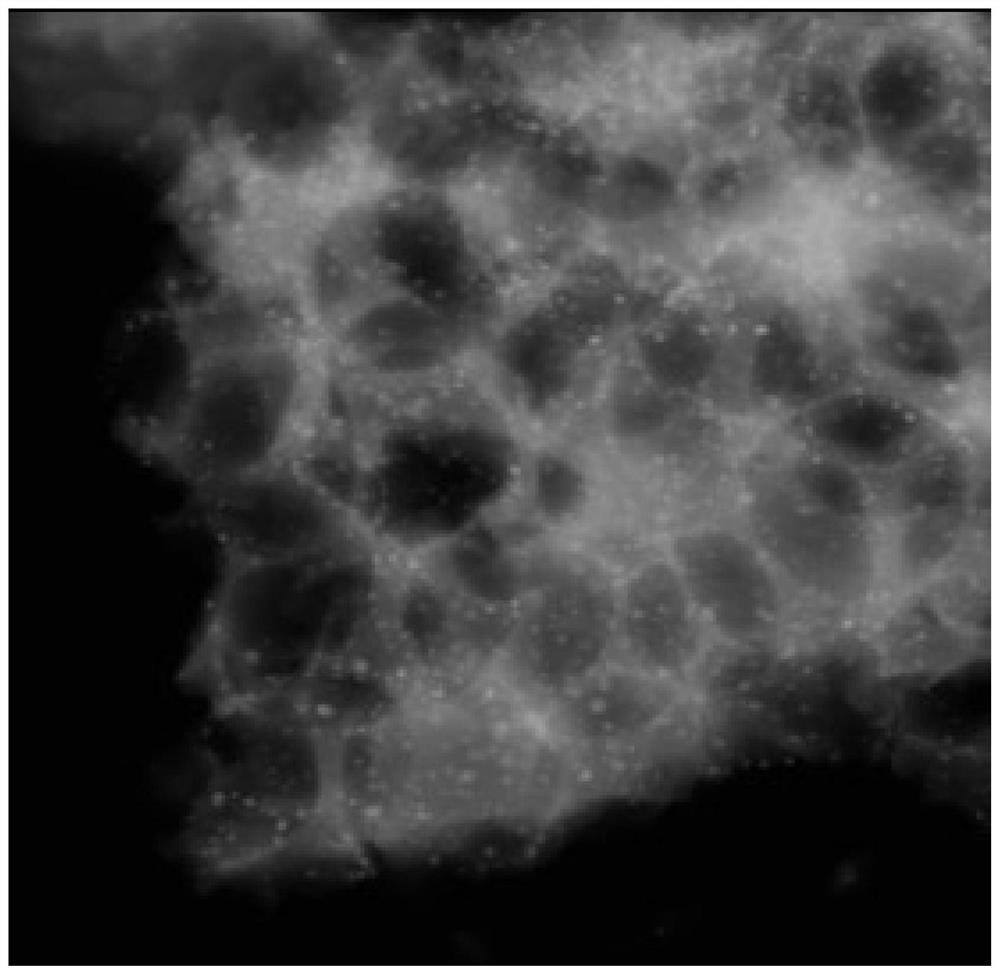

[0072] Step 1: Synthesis of Nanoscale Metal Oxide Templates

[0073] (1) Take the orthosilicate compound and the first solution according to the volume ratio of the orthosilicate compound (specifically, orthosilicate acetate) and the first solution at a ratio of 1:20, and uniformly mix under magnetic stirring Mix to obtain a mixed solution; wherein, the first solution is alcohol;

[0074] (2) Measure the same volume of saturated ammonia water as the orthosilicate compound and add it dropwise to the above mixed solution, and react for 5 hours under magnetic stirring;

[0075] (3) After the reaction, the precipitate was collected by centrifugation, washed three times with alcohol, and finally the obtained white product was dried in a drying oven at 50°C for 8 hours to obtain nano-metal oxide as a template.

[0076] Step 2: Synthesis of three-dimensional porous ca...

Embodiment 2

[0083] A method for preparing a catalytic material for sulfur reduction reaction, comprising the following steps:

[0084] Step 1: Synthesis of Nanoscale Metal Oxide Templates

[0085] (1) Take the orthosilicate compound and the first solution according to the volume ratio of the orthosilicate compound (specifically tetraethyl orthosilicate) and the first solution at a ratio of 1:45, and uniformly Mix to obtain a mixed solution; wherein, the first solution is deionized water;

[0086] (2) Measure the same volume of saturated ammonia water as the orthosilicate compound and add it dropwise to the above mixed solution, and react for 4 hours under the action of ultrasound;

[0087] (3) After the reaction, the precipitate was collected by centrifugation, washed 5 times with deionized water, and finally the obtained white product was dried in a drying oven at 80°C for 6 hours to obtain nano-metal oxide as a template.

[0088] Step 2: Synthesis of three-dimensional porous carbon-supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com