Epoxy neopentyl glycol oleate, synthesis method and application thereof

A technology of neopentyl glycol ester and epoxy oleic acid, which is applied in the synthesis field of epoxy neopentyl glycol oleate and epoxy oleic acid neopentyl glycol ester, and achieves good low-temperature impact embrittlement performance and UV blocking High efficiency, good aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

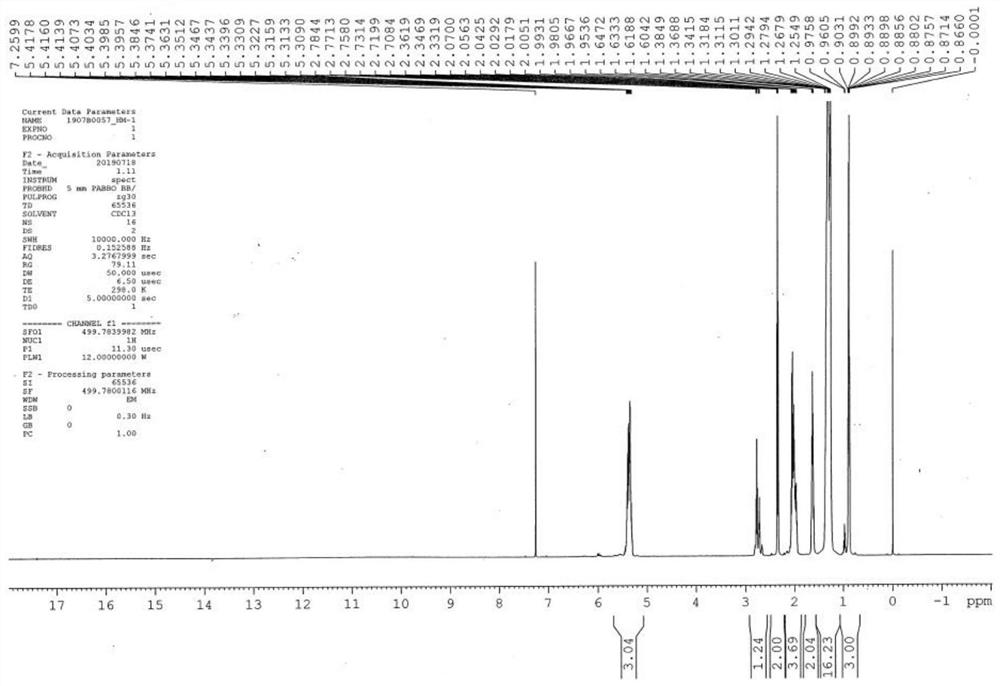

Embodiment 1

[0039] Synthesis of ethylene oleic acid neopentylene glycol esters were synthesized by oleic acid and neopad diol, and the synthesis steps include:

[0040] 1) Esterified reaction: In three round bottom flasks equipped with stirring, thermometer, reflow condenser, 513.24 g of oleic acid, 104g of neopentane glycol, 0.93 g of catalyst phosphoric acid, transfer nitrogen and stir up to 220 The temperature in ° C was held for 4 hours, and the reaction was charged for 4 hours at 250 ° C. During the intermittent feed, when the sample is less than 2.0, the reaction was completed, and the light yellow oil neopentylene glycol oleide was obtained, and the acid value was 1.93 mgKOH / g.

[0041] 2) Epoxidized reaction: 509 g of the neoplancanol oleetrate obtained in step 1), 22 g of formic acid, 0.5 g of catalyst concentrated sulfate, and four-port with stirring means, thermometer, liquid-liquid funnel, reflow contribution pipe In the round bottom flask, stir up to 60 ° C, slowly drop 50% bio...

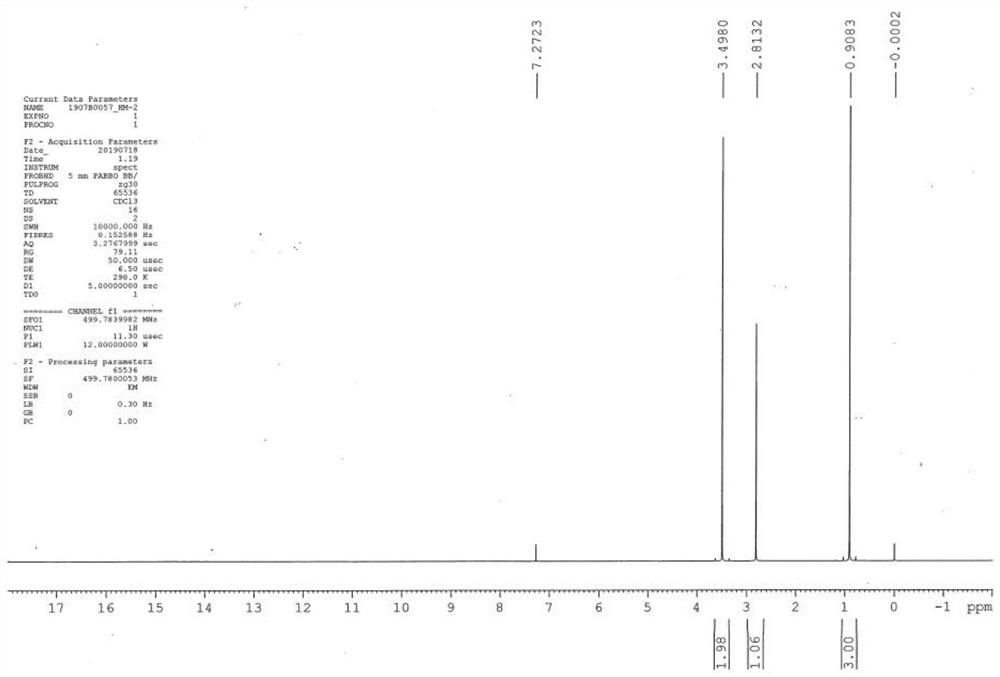

Embodiment 2

[0054] Synthesis of ethylene oleic acid neopentylene glycol esters were synthesized by oleic acid and neopad diol, and the synthesis steps include:

[0055] 1) Esterified reaction: In three round bottom flasks equipped with a stirring device, a thermometer, a reflux condensation pipe, 549.9 g of oleic acid is sequentially added, and 104 g of pentanediol, and the catalyst titanate is 1.63 g, and nitrogen is introduced. The mixture was stirred to 160 ° C, 180 ° C, 200 ° C, 2 hours, 2 hours, 230 ° C, 2 hours, 250 ° C insulation reaction for 3 hours. When the sample was less than 2.0, the reaction was completed, and the reaction was completed to give a light yellow oily neopentylene glycol oleate, and the acid value was 1.85 mgKOH / g.

[0056] 2) Epoxidized reaction: 470 g of neopentyl glycol oleanate prepared in step 1), 28 g of formic acid, 1.40 g of catalyst phosphoric acid 1.40 g of a stirring apparatus, thermometer, separatory funnel, reflow condensed tube four rounds In the und...

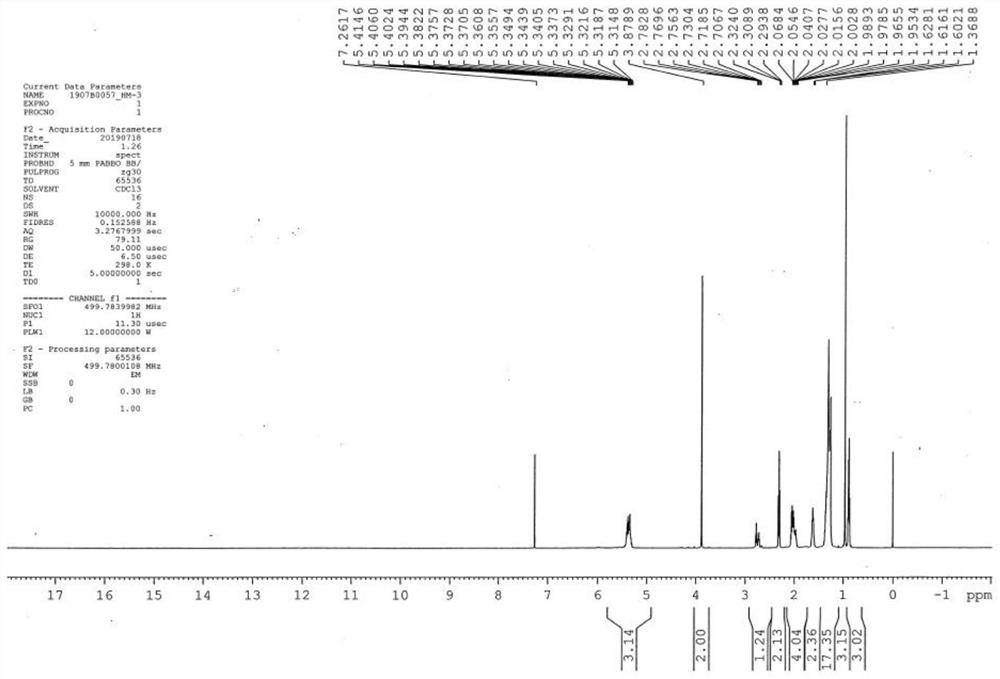

Embodiment 3

[0058] Synthesis of ethylene oleic acid neopentylene glycol esters were synthesized by oleic acid and neopad diol, and the synthesis steps include:

[0059] 1) Esterified reaction: In three round bottom flasks equipped with stirring, thermometer, reflow condensation pipe, 624 g of oleic acid, 104g of new pentanediol, 2.76 g of catalyst, penta nitrogen, stir up to 170 EtOAc EtOAc EtOAc EtOAc. When the sample is less than 2.0, the reaction is completed, the reaction is completed, resulting in a light yellow oil, and is detected, the acid value of 1.90 mgKOH / g.

[0060] 2) Epoxidized reaction: 500g of neopentyl glycol oleanide obtained in step 1), 39g of formic acid, 1.05 g of catalyst phosphoric acid to add a stirring device, a thermometer, a fluid funnel, and reflow the four-port circle In the bottom flask, stir up to 60 ° C, slowly drop 50% diodehydrate 250g with stirring, after adding 10 hours at 65 ° C, washed out of the lower acid water, the upper oil ester water, was evapora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com