Rough substrate for smooth porous surface infused with lubricating fluid, smooth porous surface infused with lubricating fluid, and preparation methods of rough substrate and smooth porous surface

A porous surface and lubricating fluid technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of unstable mechanical properties, poor adhesion between low surface energy polymers and substrates, etc., and achieve fast and convenient coating preparation The effect of large-area preparation and shortening the preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

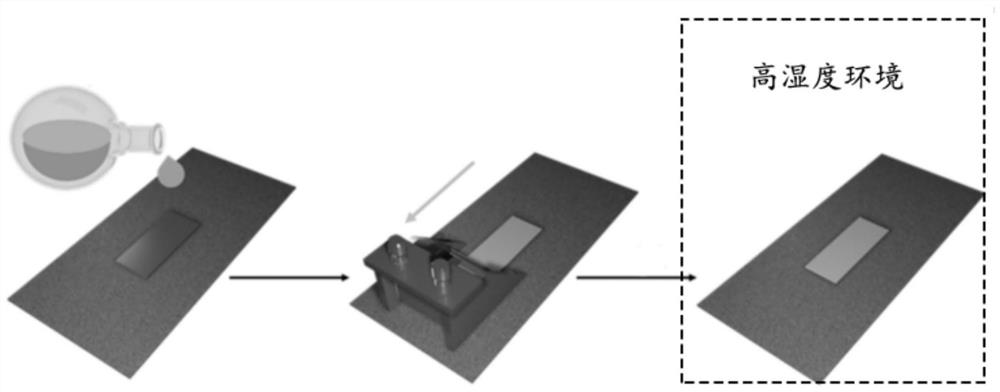

[0053] The method for preparing a smooth porous surface filled with lubricating fluid provided in the embodiments of the present application includes:

[0054] 1. Please refer to figure 1 , Mix the epoxy resin monomer and diethylenetriamine evenly in a certain proportion, centrifugally degas to obtain a uniform mixture, apply the mixture evenly on the substrate, place the substrate in a high-humidity environment to cure and obtain a lubricant for perfusion The rough substrate of the smooth porous surface of the liquid (hereinafter referred to as the rough porous substrate); figure 1 The first diagram on the left shows that the epoxy resin monomer and diethylenetriamine are mixed uniformly in a certain proportion. figure 1 The central schematic is for spreading the mixture evenly on the substrate, figure 1 The schematic diagram on the right is a schematic diagram of placing the substrate in a high-humidity environment.

[0055] 2. Soak the prepared rough porous substrate in ...

Embodiment 1

[0060] Add 10g of E44 epoxy resin and 1g of diethylenetriamine into the beaker at the same time, stir evenly with a glass rod, and then spin it with a centrifuge at 6000rpm for 6min to degas it to obtain a mixture.

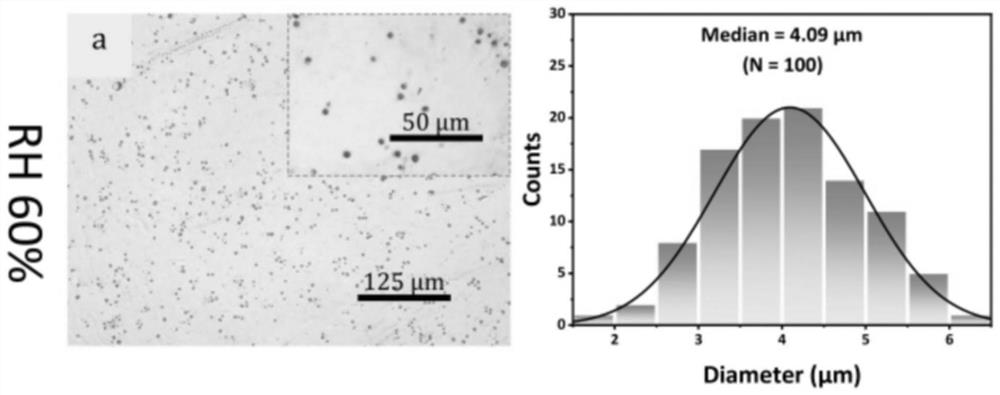

[0061] The resulting mixture was spin-coated on a glass slide with a spin coater at 6000 rpm for 1 min, and placed in an environment with a relative humidity of 90% for natural curing to obtain a rough porous substrate.

[0062] Soak the prepared rough porous substrate into 3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyl trimethyl Oxysilane ethanol solution (3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyltrimethoxysilane with Hydrophobic modification was carried out in ethanol (volume ratio: 1:99) for 30 minutes, and a hydrophobic rough porous substrate was obtained after drying. The perfluoropolyether lubricating liquid was poured into the prepared hydrophobic rough porous substrate to obtain a smooth porous substrate filled with lubricating l...

Embodiment 2

[0064] Add 10g of E44 epoxy resin and 1g of diethylenetriamine into the beaker at the same time, stir evenly with a glass rod, and then spin it with a centrifuge at 6000rpm for 6min to degas it to obtain a mixture.

[0065] The obtained mixture was spin-coated on the metal substrate with a spin coater at 3000 rpm for 30 s, and placed in an environment with a relative humidity of 90% for natural curing to obtain a rough porous substrate.

[0066] Soak the prepared rough porous substrate into 3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyl trimethyl Oxysilane ethanol solution (3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyltrimethoxysilane with Hydrophobic modification was carried out in ethanol (volume ratio: 1:99) for 30 minutes, and a hydrophobic rough porous substrate was obtained after drying. The perfluoropolyether lubricating liquid was poured into the prepared hydrophobic rough porous substrate to obtain a smooth porous substrate filled with lubricati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ice adhesion strength | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com