Anti-scratch coating and preparation method thereof

An anti-scratch and coating technology, applied to coatings, devices for coating liquid on the surface, special surfaces, etc., can solve problems such as complex operation, high cost, and environmental pollution, and achieve the effect of overcoming expensive raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

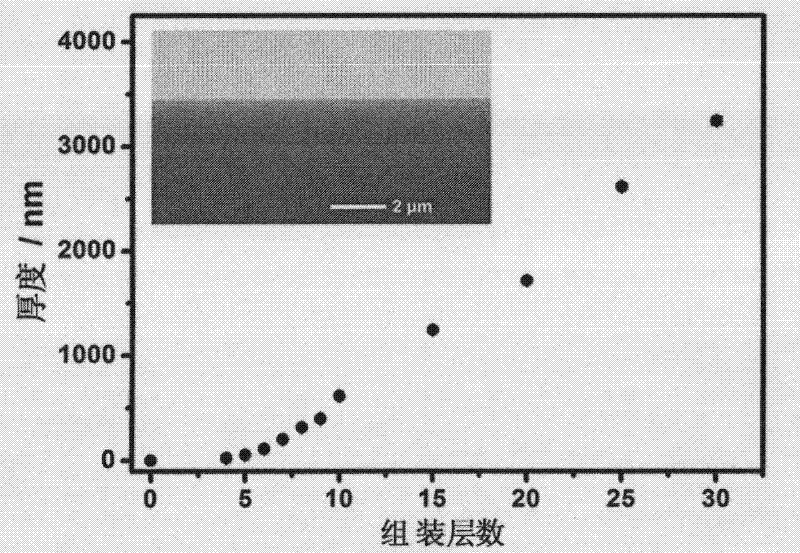

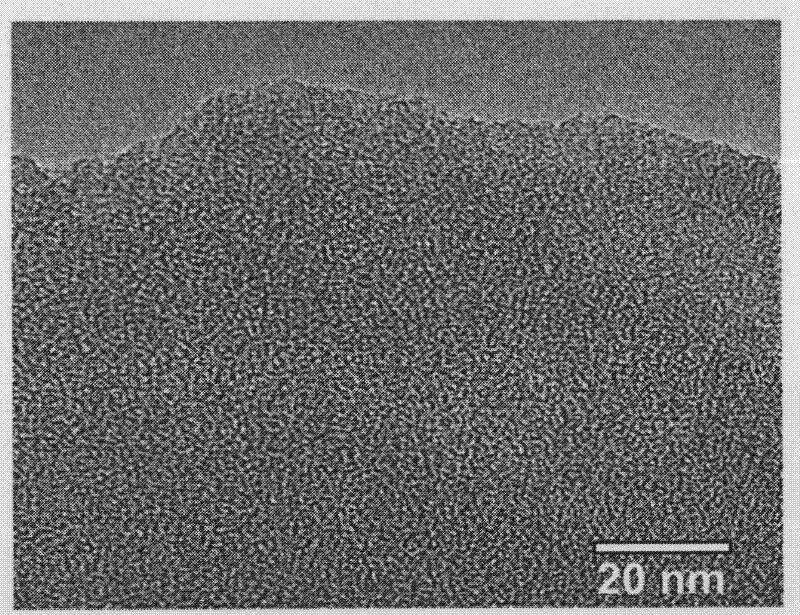

[0062] Embodiment 1: Preparation of transparent high hardness anti-scratch coating on glass or monocrystalline silicon substrate

[0063] a. Substrate treatment: The treatment method for the selected solid substrate glass or single crystal silicon wafer substrate is as follows: use toluene, acetone, chloroform, ethanol and distilled water to ultrasonically treat for 10 minutes respectively to remove various impurities attached to the surface of the substrate, and then 98%H 2 SO 4 and 30% (mass concentration) H 2 o 2 (v:v=7:3) in the mixed solution and heated to boil (30min) until no bubbles overflowed. After cooling, rinse with a large amount of distilled water, then blow dry with nitrogen, and set aside. The surface of such treated glass or quartz substrate contains a large amount of silanol; soak the treated glass or silicon wafer substrate in 1mg / mL polydimethylallyl ammonium chloride (PDDA) for 30min to make its surface undergo self-assembly A layer of positively char...

Embodiment 2

[0074] Embodiment 2: Preparation of transparent high hardness scratch-resistant coating on azobenzene polymer multilayer film

[0075] The treatment of the glass substrate is the same as in Example 1. First, the glass sheet whose surface is modified with polydiallyldimethylammonium chloride PDDA is subjected to the following operations: (1) it is immersed in a concentration of 0.5mg / mL containing The polyelectrolyte (PAC-azoBNS, which is a purple-red dye with a nitrogen phenyl group, the chemical structural formula is shown below, see the literature for the synthesis method: Langmuir 2006, 22, 7894.) in the solution for 20 minutes, and after 3 minutes and 2 minutes , 1 minute three-step deionized water rinse; (2) and then immersed in the prepared 1mg / mL polydiallyl dimethyl ammonium chloride PDDA solution for 20 minutes, take out after 3 minutes, 2 minutes, 1 minute The three-step deionized water rinse; repeat the above two processes (1) (2) for 15 cycles to obtain (PAC-azoBNS...

Embodiment 3

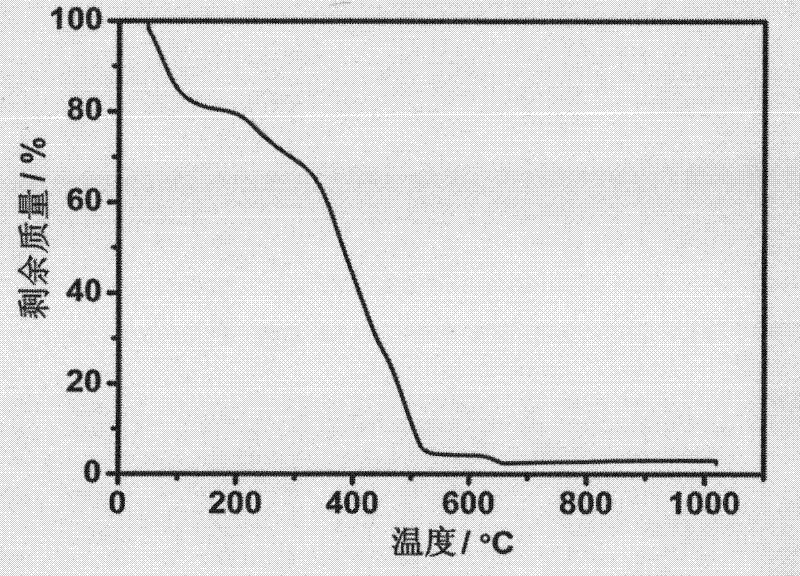

[0079] a. The substrate is made of metal aluminum sheet, which is ultrasonically treated with toluene, acetone, chloroform, ethanol and distilled water for 10 minutes respectively to remove various impurities attached to the surface of the substrate, then rinsed with a large amount of distilled water, and then blown dry with nitrogen, ready for use . Soak the treated aluminum sheet in 1 mg / mL polydimethylallyl ammonium chloride (polydiallyldimethylammonium chloride PDDA) for 30min to modify the surface with a positive layer by self-assembly. Charged quaternized amino groups, such modified aluminum flakes can be used for the preparation of layered assembled membranes based on electrostatic forces.

[0080] b. Preparation of building block solution

[0081] (1) The building block with a negative charge is polyacrylic acid-calcium carbonate (CaCO 3 ) composite solution, its configuration method is as follows: first prepare 60mL monomer concentration is the polyacrylic acid aque...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com