Perspiration warm-keeping pajamas fabric and preparation method thereof

A technology for fabrics and pajamas, applied in the field of sweat-wicking and warm pajamas fabrics and their preparation, can solve problems such as health hazards, yellowing and discoloration of fabrics, easy adhesion of dander, etc., and achieve good antibacterial properties, comfortable fabrics, and simple production processes. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

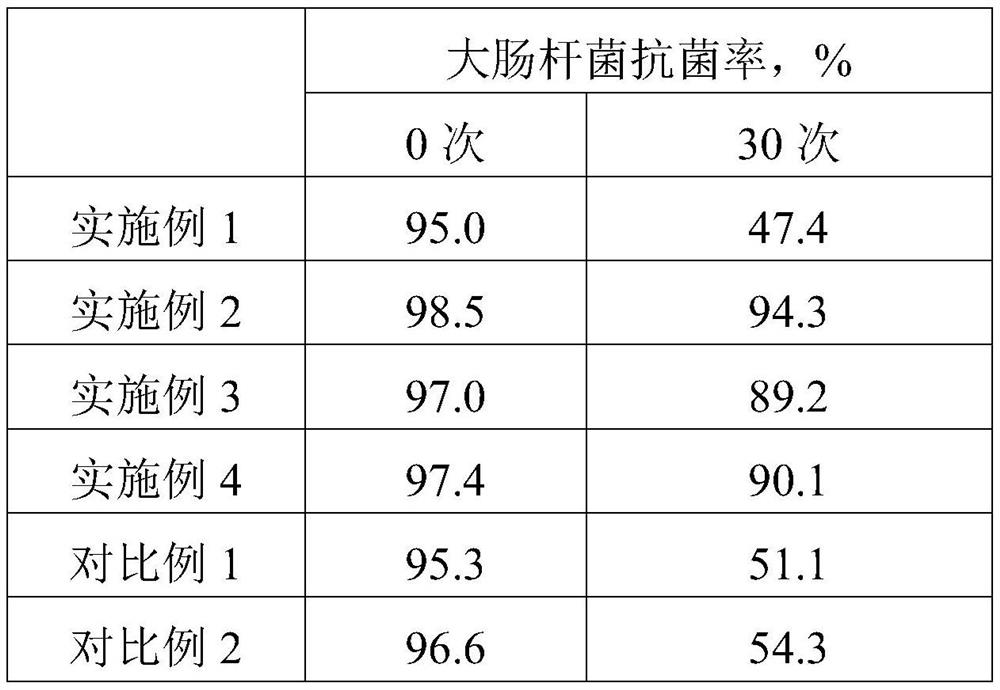

Examples

Embodiment 1

[0050] A preparation method for sweat-wicking warm pajamas fabric, comprising the following steps:

[0051] (1) Fabric weaving: 40 parts by weight of coolmax fiber, 10 parts by weight of chitin fiber, and 80 parts by weight of cotton fiber are used to weave the fabric gray cloth according to the conventional method, and the weight of the fabric gray cloth is 100g / m 2 ;

[0052] (2) Finishing of the fabric: at room temperature, arrange the fabric blank obtained in step (1) in a 1.5wt% antibacterial finishing agent solution and immerse it for 2 hours at a bath ratio of 1g: 30mL, and control the excess rate to 90%. Dry for 2 minutes, and then bake at 120°C for 2 minutes to obtain sweat-wicking and thermal pajamas fabric.

Embodiment 2

[0054] A preparation method for sweat-wicking warm pajamas fabric, comprising the following steps:

[0055] (1) Fabric weaving: 40 parts by weight of coolmax fiber, 10 parts by weight of chitin fiber, and 80 parts by weight of cotton fiber are used to weave the fabric gray cloth according to the conventional method, and the weight of the fabric gray cloth is 100g / m 2 ;

[0056] (2) Fabric gray cloth pretreatment: Treat the fabric gray cloth with atmospheric pressure plasma jet for 150s to obtain the pretreated fabric gray cloth; wherein helium is used as the carrier and oxygen is the reaction gas; and the volume ratio of helium and oxygen is 98: 2 mixed;

[0057] (3) Finishing of the fabric: at room temperature, the pretreated fabric embryo obtained in step (2) is placed in a 1.5wt% polyvinyl alcohol / lactone type sophorolipid solution for immersion for 1 hour at a bath ratio of 1g:30mL, and the rolling is controlled. The remaining rate is 90%, dried at 100°C for 3 minutes, a...

Embodiment 3

[0062] A preparation method for sweat-wicking warm pajamas fabric, comprising the following steps:

[0063] (1) Fabric weaving: 40 parts by weight of coolmax fiber, 10 parts by weight of chitin fiber, and 80 parts by weight of cotton fiber are used to weave the fabric gray cloth according to the conventional method, and the weight of the fabric gray cloth is 100g / m 2 ;

[0064] (2) Fabric gray cloth pretreatment: Treat the fabric gray cloth with atmospheric pressure plasma jet for 150s to obtain the pretreated fabric gray cloth; wherein helium is used as the carrier and oxygen is the reaction gas; and the volume ratio of helium and oxygen is 98: 2 mixed;

[0065] (3) Finishing of the fabric: at room temperature, arrange the fabric embryo obtained in step (1) in a 1.5wt% polyvinyl alcohol / lactone type sophorolipid solution and immerse it for 1 hour at a bath ratio of 1g:30mL to control the excess rate 90%, dried at 100°C for 3 minutes, and then baked at 120°C for 2 minutes to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

| Surface resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com