Lithium metal negative electrode and preparation method and application thereof

A lithium metal negative electrode and reaction technology, applied in the direction of negative electrode, battery electrode, active material electrode, etc., can solve the problems of inability to accommodate volume expansion, inability to disperse lithium dendrite tip current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

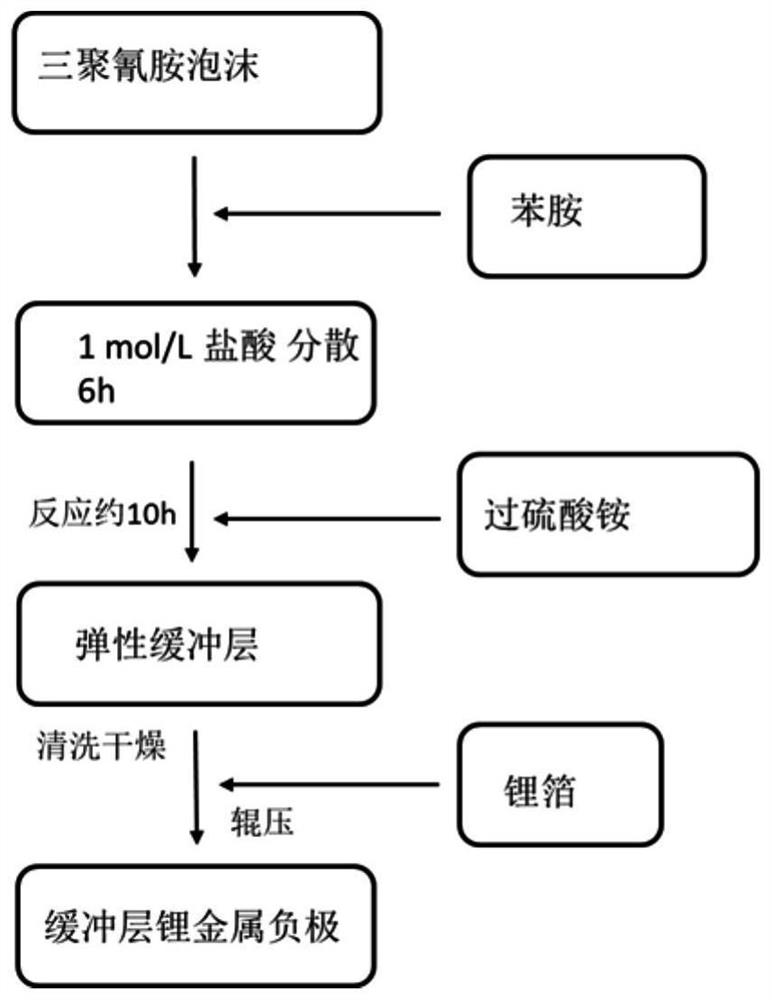

[0026] The process flow for preparing metal lithium negative electrode provided by the embodiment of the present invention is as follows: figure 1 shown.

[0027] The invention provides a method for preparing a lithium metal negative electrode, comprising:

[0028] After mixing the melamine foam and the aniline solution, let it stand to obtain a mixed solution;

[0029] reacting the mixed solution with ammonium persulfate to obtain a reaction product;

[0030] The reaction product and the lithium foil are rolled and combined to obtain a metal lithium negative electrode.

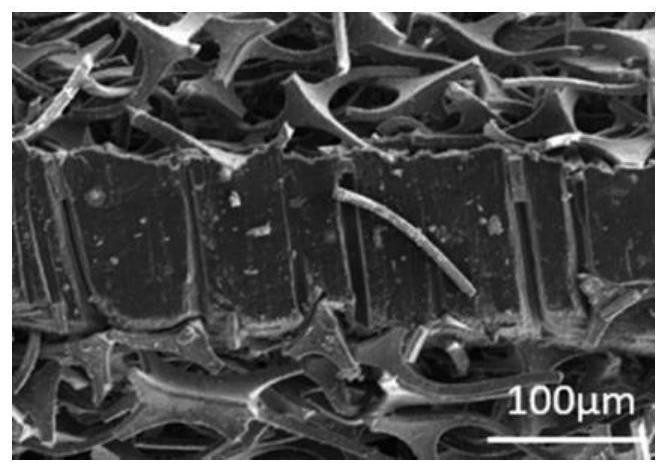

[0031] In the present invention, the melamine foam is preferably a sheet. In the present invention, the thickness of the melamine foam is preferably 1.8-2.5 mm, more preferably 2-2.2 mm. In the present invention, the melamine foam is preferably melamine-formaldehyde resin, preferably formed by the reaction of formaldehyde and melamine, and the porosity is preferably above 99.9%. In the present invention,...

Embodiment 1

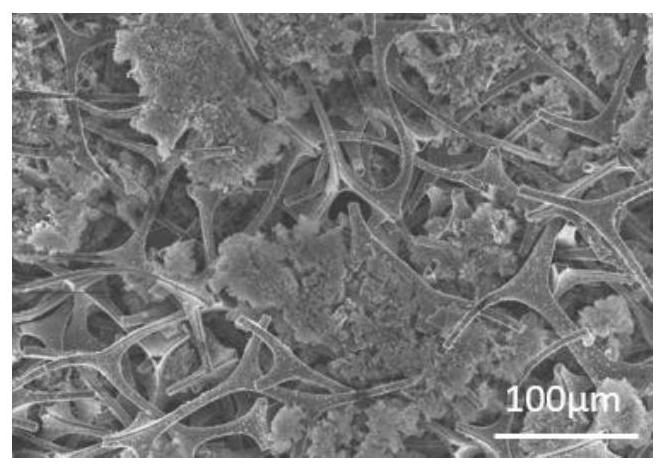

[0055] Take 30 pieces of melamine foam with a thickness of about 1.8mm, an area of 3*4cm, and a total mass of 0.69g. Use acetone and alcohol to ultrasonically clean them for 30 minutes, then place them in a blast desiccant at 60°C for later use, and weigh 3.70 pieces with an analytical balance. 1g of aniline is dispersed in 280mL of 1moL / mL hydrochloric acid solution, melamine foam is added, and left to stand in an ice bath for 4 hours; 4.10g of ammonium persulfate is weighed with an analytical balance and added to the mixed hydrochloric acid solution of melamine foam and aniline , fully dissolved, and left to react under ice bath conditions for 8 hours; the elastic buffer layer material prepared after the reaction was taken out from the hydrochloric acid, and washed with deionized water several times to remove the excess and over-reacted melamine foam skeleton surface. The polyaniline particles were then dried in a blast oven at 60°C for later use.

[0056] The dried elasti...

Embodiment 2

[0060] 20 pieces of melamine foam with a thickness of about 1.8mm, an area of 5*6cm, and a total mass of 1.38g were ultrasonically cleaned with acetone and alcohol for 30 minutes, then dried in a blast desiccant at 60°C for later use, and weighed 7.45 with an analytical balance. G of aniline was dispersed in 550mL of 1moL / mL hydrochloric acid solution, melamine foam was added, and the mixture was allowed to stand in an ice bath for 5 hours. Weigh 8.28g of ammonium persulfate with an analytical balance and add it to the mixed hydrochloric acid solution of melamine foam and aniline, fully dissolve, and let it stand for 10 hours under ice bath conditions. Take out the elastic buffer layer material prepared after the reaction from the hydrochloric acid, wash it with deionized water several times, wash off the surface of the melamine foam skeleton, and place the excess and over-reacted polyaniline particles in a blast oven at 60°C for later use. .

[0061] Cut the dry elastic bu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com