Sitafloxacin fine granule and preparation process thereof

A technology of sitafloxacin and sitafloxacin hydrate, which is applied in the field of medicine, can solve the problems of poor dispersion of sitafloxacin particles, large particle size distribution and poor uniformity of sitafloxacin fine particles, and achieve Good dissolution effect, low cost and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

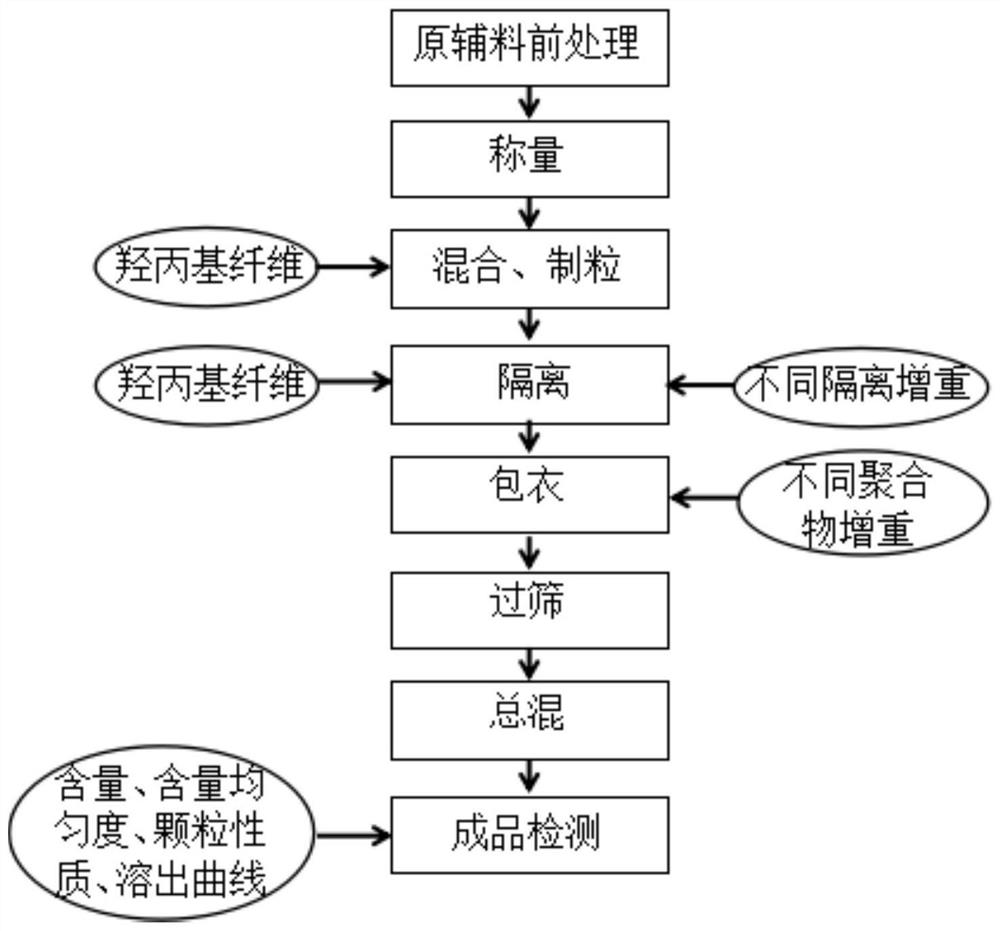

[0054] Embodiment 1 preparation method is:

[0055] (1) Pre-treatment of raw and auxiliary materials: manually pass sitafloxacin hydrate through a 200-mesh sieve, mannitol through a 80-mesh sieve, and microcrystalline cellulose through a 80-mesh sieve after crushing.

[0056] (2) Mixing: Weigh and sieve sitafloxacin hydrate, microcrystalline cellulose, mannitol, and cornstarch according to the prescription amount, pass through a No. 2 pharmacopoeia sieve and mix.

[0057] (3) Preparation of binder solution: Take the calculated hydroxypropyl cellulose HPC-L and add it into a beaker and add purified water to dissolve it.

[0058] (4) Granulation: Put the mixture of raw and auxiliary materials in the top spraying device of the fluidized bed, premix and preheat, and then spray the binder solution. After the granulation is finished, dry, start to detect the moisture after 3 minutes of drying, and then take samples every 5 minutes to measure the moisture content of the granules. Wh...

Embodiment 2-9

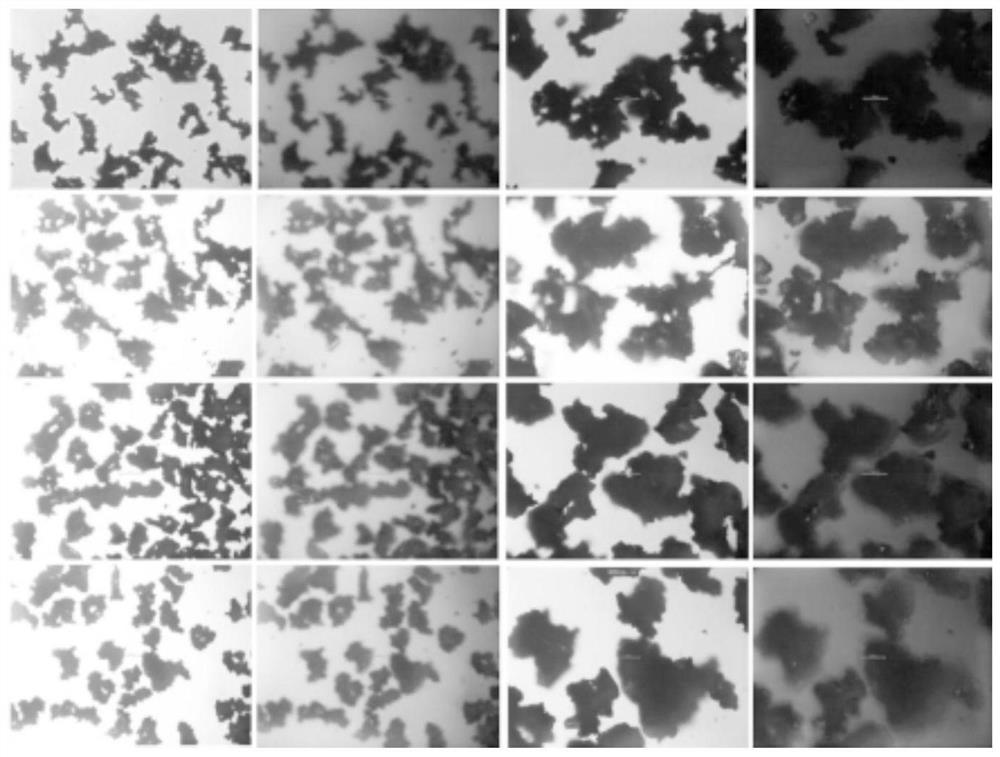

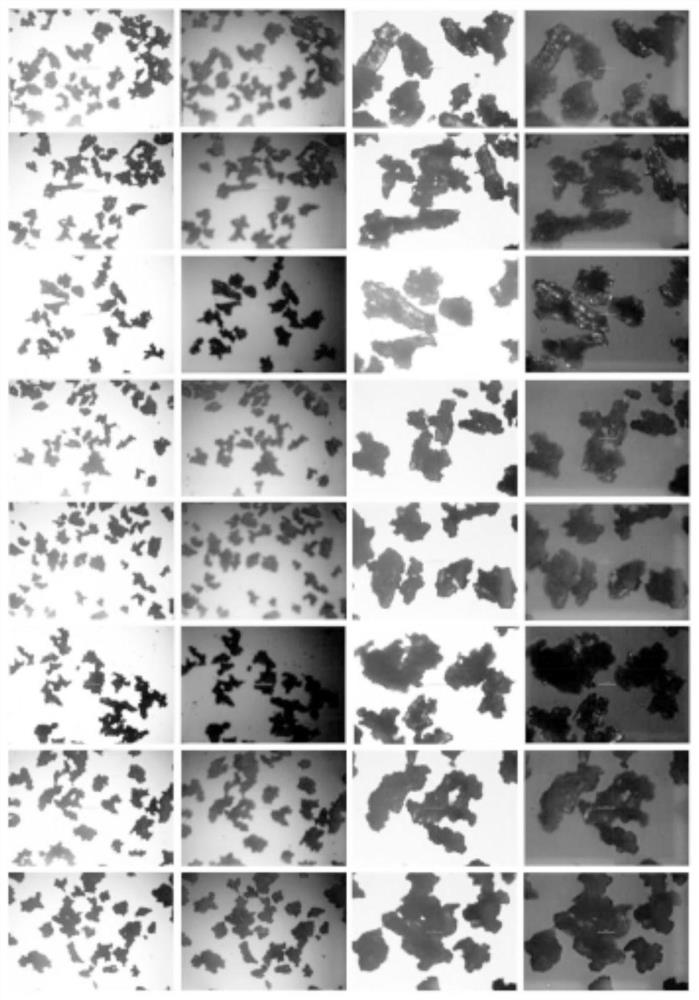

[0071] In order to improve the problems existing in the preparation of granules in Example 1, the experiment at this stage changed the formulation of the coating solution, reduced the amount of hydroxypropyl cellulose in the prescription, and investigated the differences in the properties of the finished product under different isolation and coating weight gain conditions.

[0072] The fluidity of the particle inner core becomes better after isolation, the particle size decreases slightly at 2.5% of the isolation weight gain, the particle size distribution tends to be concentrated, and the fluidity increases significantly; the particle size of the 5% isolation weight gain increases significantly, and the degree of particle size concentration is almost unchanged. Liquidity is significantly improved. At 2.5% isolation weight gain, the particle size after coating did not change much, the particle size distribution tended to be dispersed, and the fluidity increased slightly; at 5% ...

Embodiment 10-11

[0089] In Examples 10 and 11, the purpose of inhibiting the disintegration speed of self-made granules was achieved by increasing the amount of hydroxypropyl cellulose and reducing the amount of corn starch. Dissolution test results ( Figure 4) shows that the amount of corn starch formulation has a certain impact on the dissolution curve. After reducing the amount of corn starch formulation, the dissolution rate of the granules of Example 11 in the pH5.0 medium is significantly lower than that of the granules of Example 10, and the dissolution rate at the end point is also significantly reduced. The expected result is consistent with the formulation of the action plan in the pH5.0 medium, that is, the slower disintegration is not conducive to the dissolution of sitafloxacin API in high solubility medium.

[0090] A kind of formula of sitafloxacin fine granule embodiment 10-11 of table 6

[0091]

[0092]

[0093] 2. Detection test and effect

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com