Filler with low dielectric constant, epoxy composite material and preparation method thereof

A low dielectric constant, composite material technology, applied in the field of composite materials, can solve the problems of low dielectric constant, poor hydrothermal stability and thermal stability, and reduce the dielectric constant of epoxy resin, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

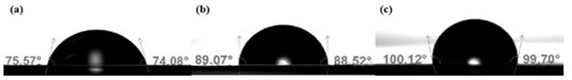

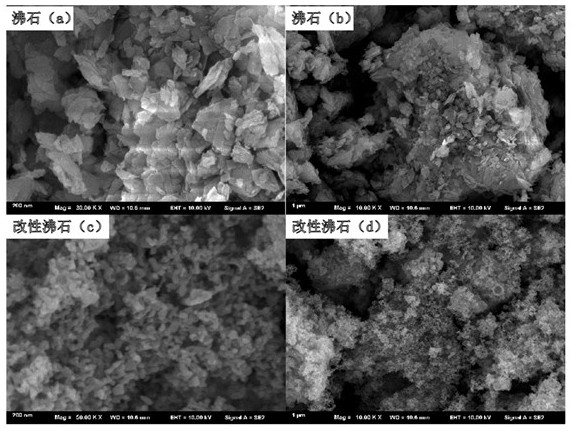

[0055]In the first step, put the zeolite powder with a particle size ranging from 100 mesh to 500 mesh in a muffle furnace for 3 hours at 200°C, add 2.5g of zeolite powder to 75g of deionized aqueous solution, stir at room temperature for 10min, and transfer to ultrasonic dispersion Ultrasonic dispersion for 1h, and keep stirring. Add 75g of absolute ethanol, 1.4g of template agent cetyltrimethylammonium bromide and 0.24g of sodium hydroxide. After continuing the ultrasonic dispersion for 30 minutes, slowly add 12.5 g of ethyl orthosilicate dropwise to the mixed solution, and place the reaction vessel in a water bath, and keep the temperature at 40°C for 4 hours. After the reaction, the resulting mixture was filtered, washed, and moved to an oven for drying. Transfer it to a muffle furnace at 600 degrees Celsius and bake it for 4 hours to obtain a modified zeolite with a mesoporous silica-coated structure, that is, a low dielectric constant filler.

[0056] In the second ste...

Embodiment 2 5

[0058] The difference from Example 1 is:

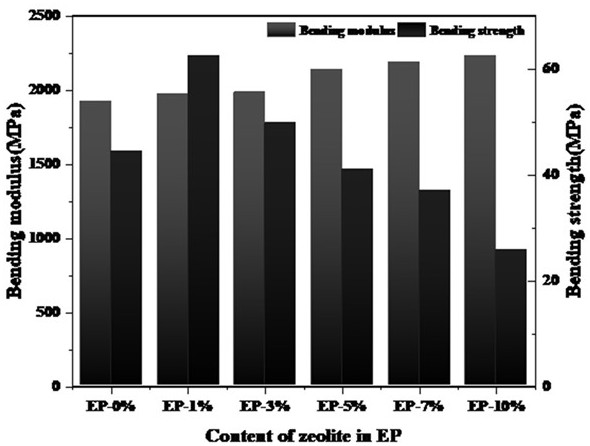

[0059] In the second step, the epoxy resins with low dielectric constant fillers added to 3g, 5g, 7g or 10g and 100g were physically blended through a high-speed disperser, and vacuumized to obtain mesoporous silica coatings. For the modified zeolite / epoxy resin mixture of the coating structure, 70g of epoxy curing agent and 0.5g of accelerator were added to the mixture, and the resulting mixture was poured into a mold, cured at 80 degrees Celsius for 2 hours, and cured at 120 degrees Celsius for 4 hours. That is, an epoxy composite material doped with a modified zeolite coated with silica is prepared.

[0060] First, the zeolite powder is heat-treated and modified by heat treatment, and the roasted zeolite is coated and modified by mesoporous silica to obtain a modified zeolite with a mesoporous silica-coated structure, that is, a low dielectric constant filler. Mesoporous silica has huge specific surface area and pore volume, adjus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com