Imidazole-enhanced ultrahigh-temperature-resistant liquid rubber plug and gel forming test improvement method thereof

An imidazole compound and ultra-high temperature technology, applied in chemical instruments and methods, using stable tension/pressure to test the strength of materials, measuring devices, etc., can solve problems such as high cost and large error in test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The invention provides a method for preparing an imidazole-enhanced ultra-high temperature resistant liquid rubber stopper, which mainly includes the following steps:

[0034] S1: Dissolve a certain mass percentage of imidazole in 45ml of water. After stirring and fully dissolving, take 45ml of imidazole solution as the formula base solution. Add the stabilizer and the nanometer material sequentially into 45ml of the imidazole solution, set the rotation speed at 400r / min, and stir for 2 hours.

[0035] S2: After the stabilizer and nanomaterials are uniformly dispersed, add the polymer, set the speed at 300-400r / min, and stir for 5 hours. Then add a cross-linking agent (diluted with 5 ml of aqueous solution) to prepare the initial mother solution of imidazole-enhanced ultra-high temperature resistant liquid rubber stopper.

[0036] In the above steps, the mass percentage is calculated based on 50ml, but a small part of the solution is reserved in advance for dilution of...

Embodiment 1

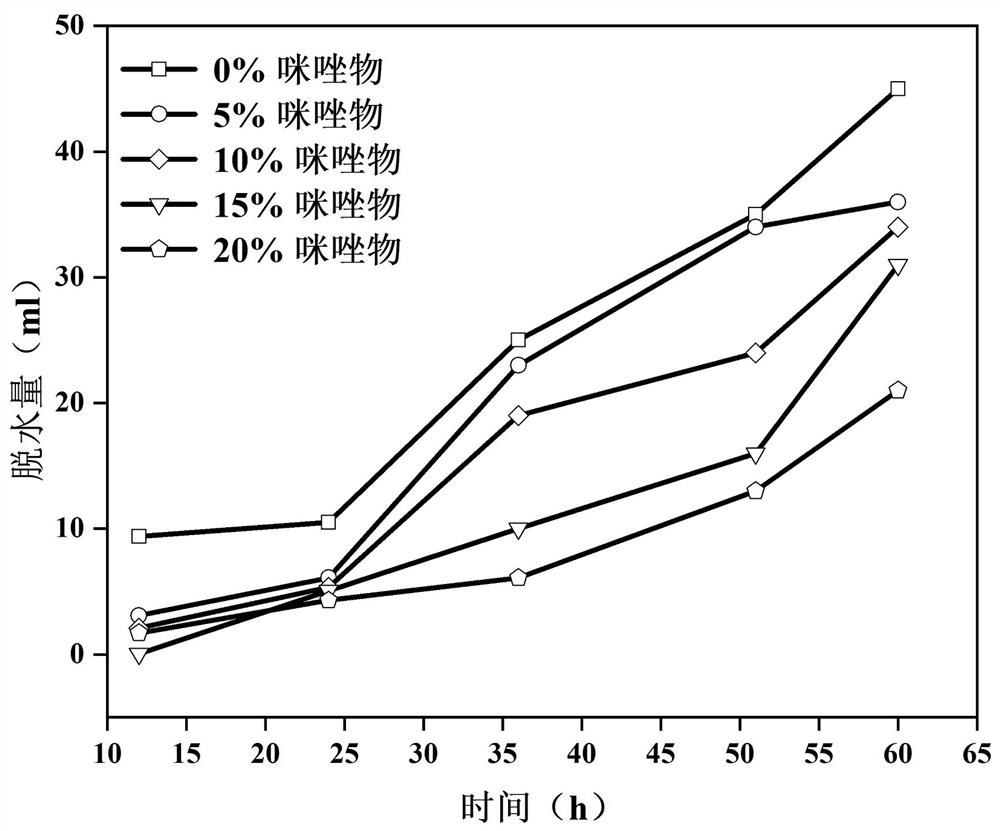

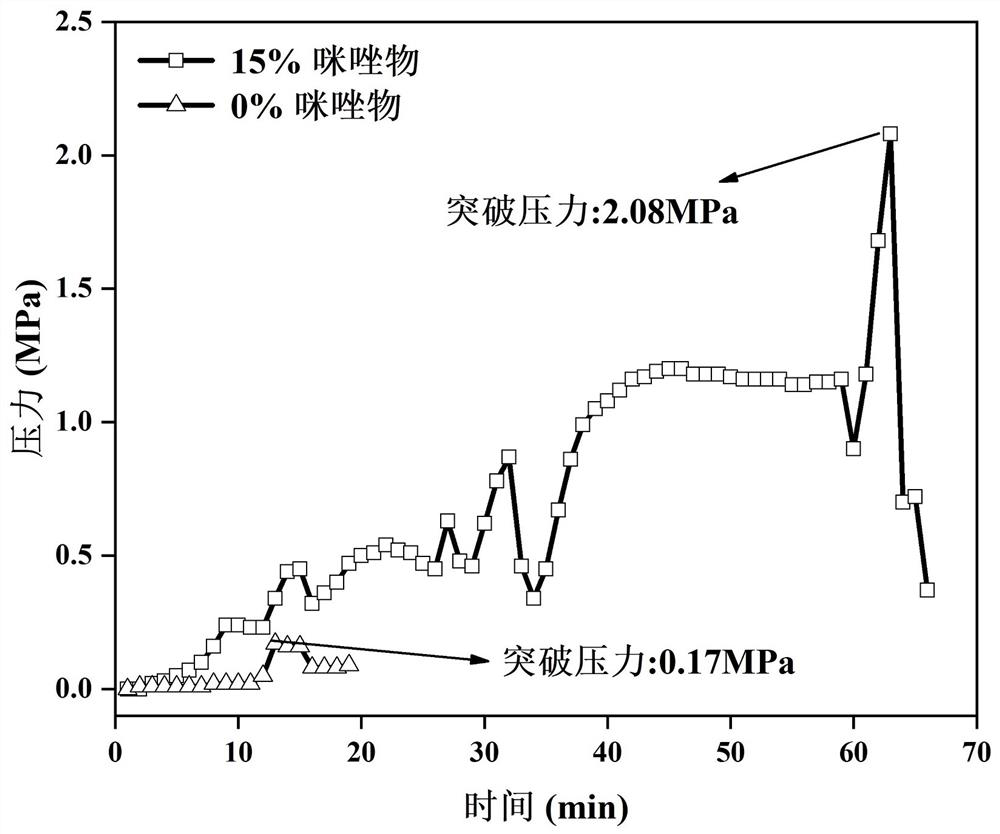

[0050] This example provides an imidazole-enhanced anti-ultra-high temperature liquid rubber stopper, the preparation method of which is carried out according to steps S1 and S2, specifically by mass percentage: 0-20% imidazole (1,2-dimethylimidazole) + 0.2% stabilizer (thiourea) + 2% nanomaterials (mass ratio of silicon dioxide and hectorite 3:1) + 2% polymer (sulfonated polyacrylamide and acrylamide 3:1) + 1% crosslinking Joint agent (polyethyleneimine). It is worth noting that polyethyleneimine is calculated by volume percentage, and 0% imidazole rubber stopper system is used as a comparative example.

Embodiment 2

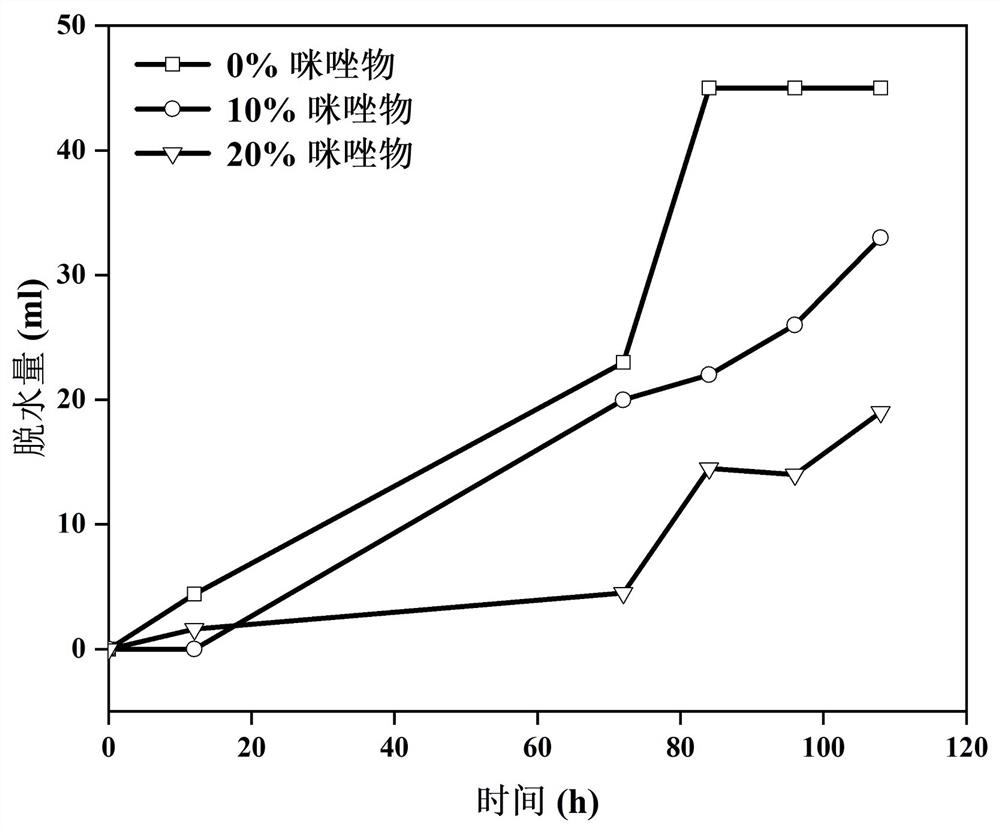

[0052] This example provides an imidazole-enhanced anti-ultra-high temperature liquid rubber stopper, the preparation method of which is carried out according to steps S1 and S2, specifically in terms of mass percentage: 0-20% imidazole (1,2-dimethylimidazole and Trimethylsilimidazole (mass ratio 4:1)+0.4% stabilizer (thiourea)+4% nanomaterials (mass ratio of silica to sepiolite 3:1)+4% polymer (sulfonated polyacrylamide Acrylamide 3:1)+2% crosslinking agent (mass ratio of polyethyleneimine to hexamethylenetetramine 4:1). It is worth noting that in the process of diluting the crosslinking agent, hexamethylenetetramine was dissolved first, and then polyethyleneimine was diluted, and the 0% imidazole rubber stopper system was used as a comparative example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com