Chlorogenic acid-rich wine and production method thereof

A production method, chlorogenic acid technology, applied in the field of brewing engineering, can solve the problems of high cost, influence of wine flavor, complex extraction process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

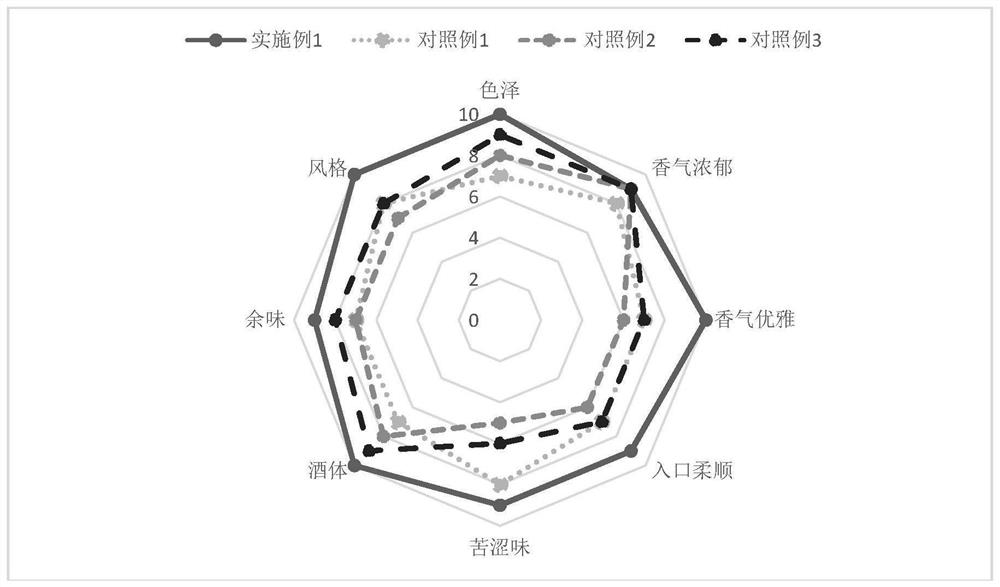

Embodiment 1

[0049] 1. Prepare chlorogenic acid extract, the steps are as follows:

[0050] Use a beater to beat 250Kg of Aronia fruit harvested in the same year into powders with a diameter of about 3-5mm, and transport them to the enzymatic hydrolysis tank. Add 36g pectinase (equivalent to 5040U / Kg of enzyme activity), 25g tannase (equivalent to 10000U / Kg of enzyme activity) and 40g cellulase (equivalent to Enzyme activity 3200U / Kg), 41g β-glucosidase (equivalent to enzyme activity 4920U / Kg); heat up to 50°C at a rate of 2°C / min, maintain for 30min, then heat up to 65°C for 15min, filter; filter the filtrate Carry out reverse osmosis concentration, operating temperature 35 ℃, concentrate to 1 / 5 of original fruit mass, obtain chlorogenic acid extract 50Kg.

[0051] 2. Preparation of distiller's mother:

[0052] Weigh 0.2g / kg of dry red wine yeast according to the pulp to be fermented, add 40°C demineralized water and pulp to be fermented, the mass ratio of dry red wine yeast, softened w...

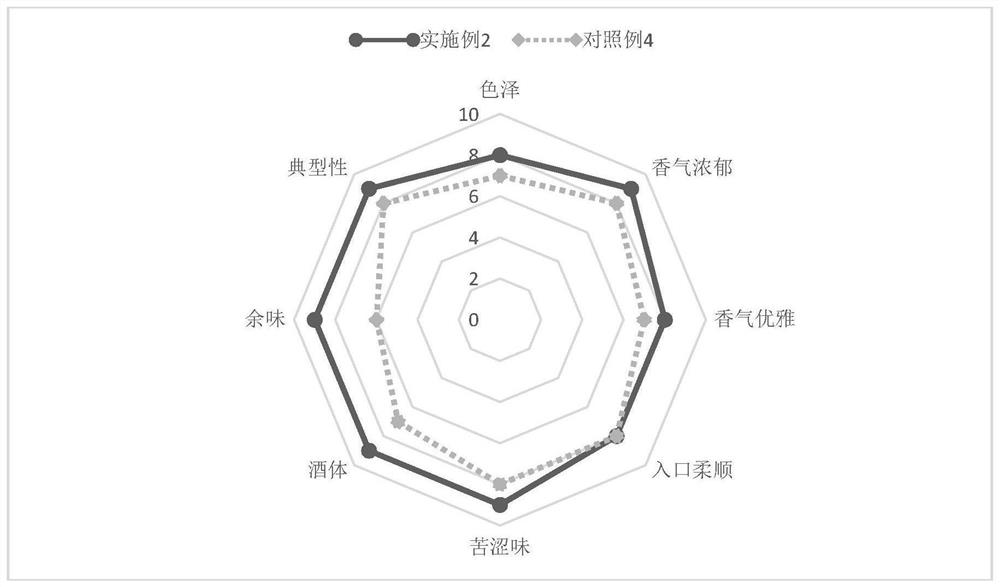

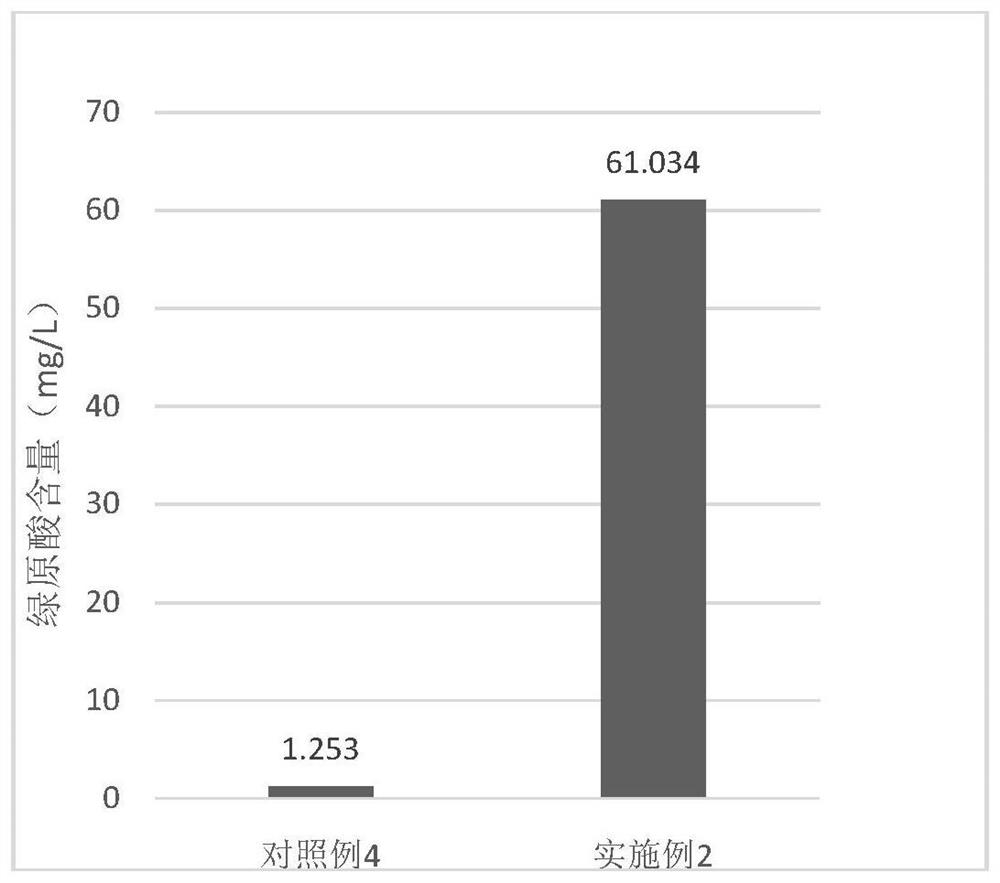

Embodiment 2

[0087] 1. Prepare chlorogenic acid extract, the steps are as follows:

[0088] Weigh 300Kg of Aronia berry pulp, put it into an enzymatic hydrolysis tank, thaw it quickly, add 68g of pectinase (equivalent to 7933U / Kg of enzyme activity), 15g of tanninase (equivalent to 5000U / Kg of enzyme activity) , 75g cellulase (equivalent to enzyme activity 5000U / Kg), 30g β-glucosidase (equivalent to enzyme activity 3000U / Kg); heat up to 45°C at a speed of 2°C / min, maintain 40min, and then heat up to 70 Maintain the temperature at ℃ for 10 minutes, filter; carry out reverse osmosis concentration on the filtrate, operating temperature 40 ℃, concentrate to 1 / 3 of the mass of the original fruit, and obtain 100Kg of chlorogenic acid extract.

[0089] 2. Preparation of distiller's mother:

[0090] Weigh 0.3g / kg of dry red wine yeast according to the pulp to be fermented, add 40°C demineralized water and pulp to be fermented, the mass ratio of dry red wine yeast, softened water, and pulp to be f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com