Tin oxide-bismuth oxychloride composite particle as well as preparation method and application thereof

A technology of bismuth oxychloride and composite particles, which is applied to electrodes, electrolysis processes, electrolysis components, etc., can solve the problems of poor dispersion performance of bismuth element, low material utilization rate, poor catalytic performance, etc., to avoid rapid hydrolysis and achieve good conductivity. , the effect of uniform particle dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

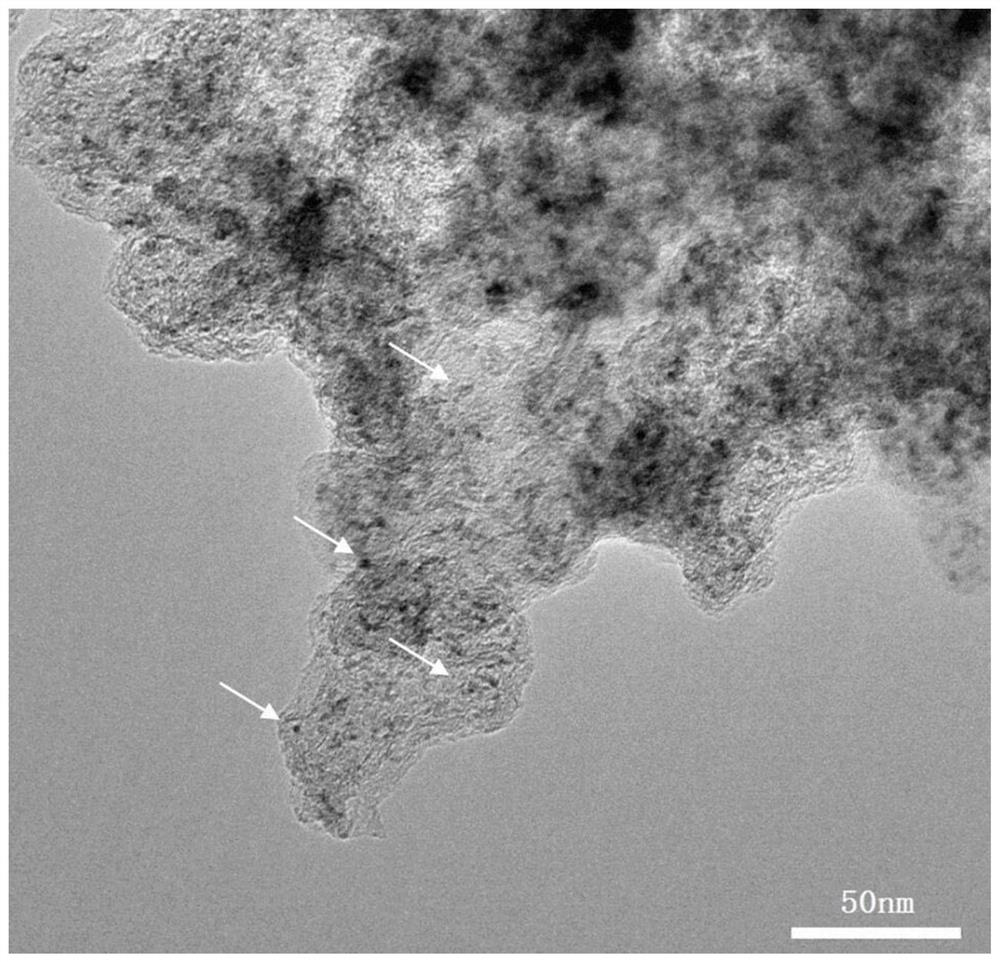

[0037] A kind of tin oxide-bismuth oxychloride composite particle, its preparation method comprises the following steps:

[0038] 1) 0.194g (0.0004mol) of Bi(NO 3 ) 3 ·5H 2 O was added to 17mL of ethylene glycol, and then 0.36g (0.0016mol) of SnCl 2 2H 2 0, ultrasonic 15min, then add the ethanol of the conductive carbon black of 200mg and 34mL, ultrasonic 30min, obtain reaction mixture;

[0039] 2) Add the reaction mixture to a polytetrafluoroethylene-lined reactor, react at 160°C for 2 hours, then cool to room temperature, filter with suction, wash the filtered solid with deionized water and ethanol, dry in vacuum, and grind to obtain tin oxide - Bismuth oxychloride composite particles (referred to as SnO 2 -BiOCl / C).

Embodiment 2

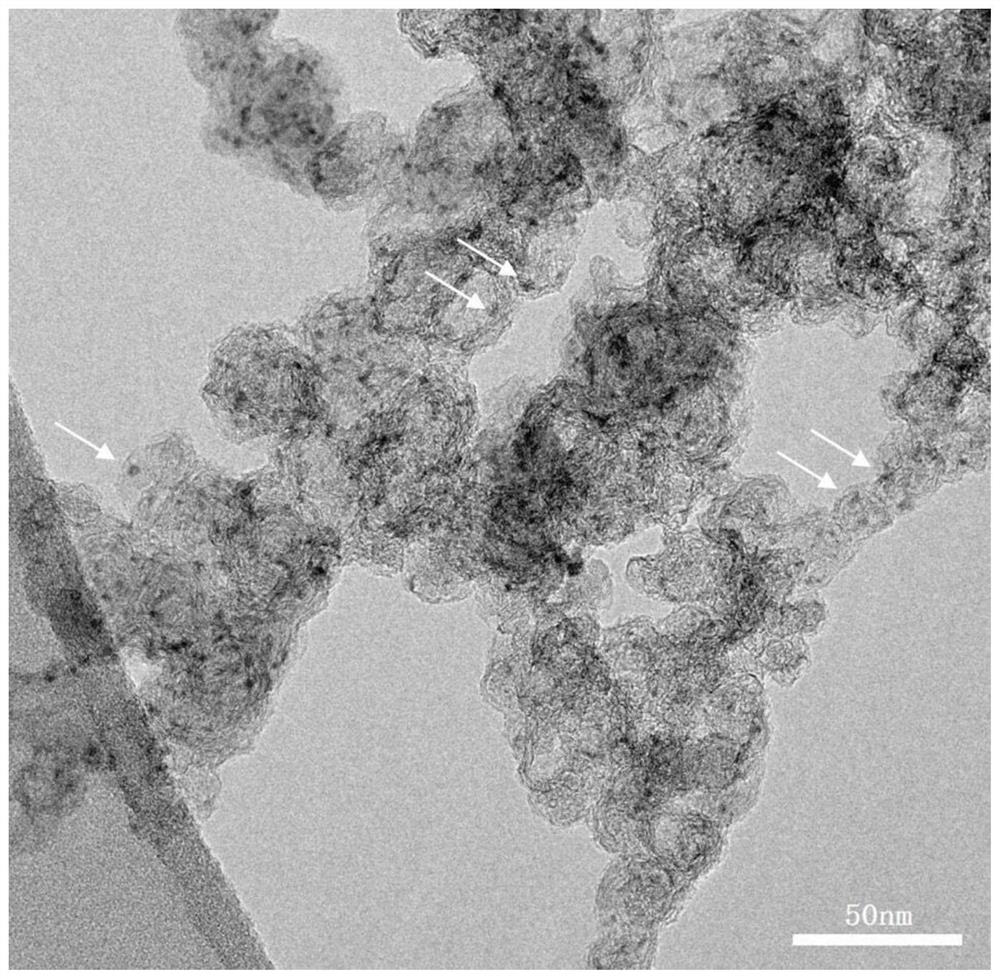

[0041] A kind of tin oxide-bismuth oxychloride composite particle, its preparation method comprises the following steps:

[0042] 1) 0.647g (0.0013mol) of Bi(NO 3 ) 3 ·5H 2 Add O to 17mL of ethylene glycol, and then add 0.151g (0.00067mol) of SnCl 2 2H 2 0, ultrasonic 15min, then add the ethanol of the conductive carbon black of 200mg and 34mL, ultrasonic 30min, obtain reaction mixture;

[0043] 2) Add the reaction mixture to a polytetrafluoroethylene-lined reactor, react at 160°C for 2 hours, then cool to room temperature, filter with suction, wash the filtered solid with deionized water and ethanol, dry in vacuum, and grind to obtain tin oxide - bismuth oxychloride composite particles.

Embodiment 3

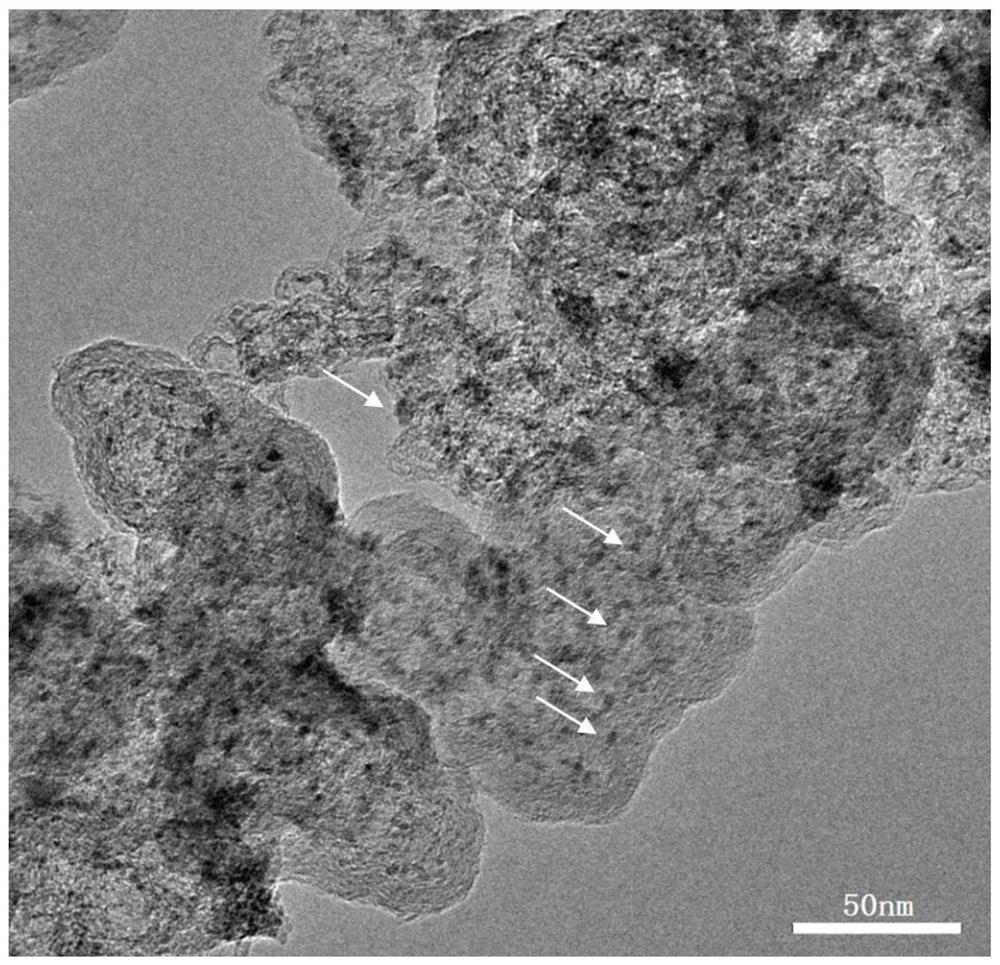

[0045] A kind of tin oxide-bismuth oxychloride composite particle, its preparation method comprises the following steps:

[0046] 1) 0.776g (0.0016mol) of Bi(NO 3 ) 3 ·5H 2 Add O to 17mL of ethylene glycol, and then add 0.09g (0.0004mol) of SnCl 2 2H 2 0, ultrasonic 15min, then add the ethanol of the conductive carbon black of 200mg and 34mL, ultrasonic 30min, obtain reaction mixture;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com