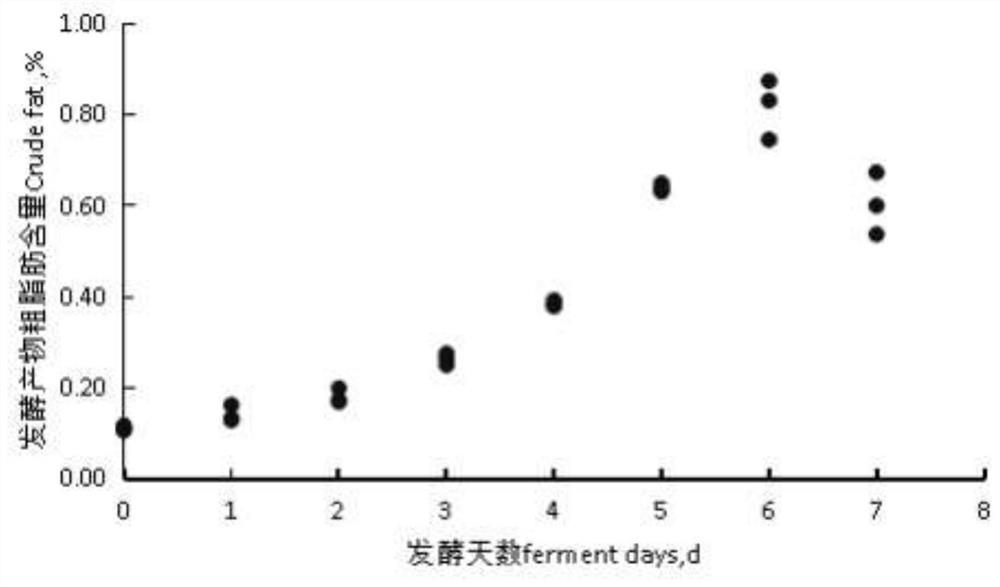

Method for converting rice straw crude fibers into crude fat through grease microbial fermentation

A technology of rice straw and crude fat is applied in the field of biological feed production where microbial fermentation improves the nutritional value of rice straw, and can solve the problems of poor palatability, restricted feed routes, low animal digestibility and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment ( 1

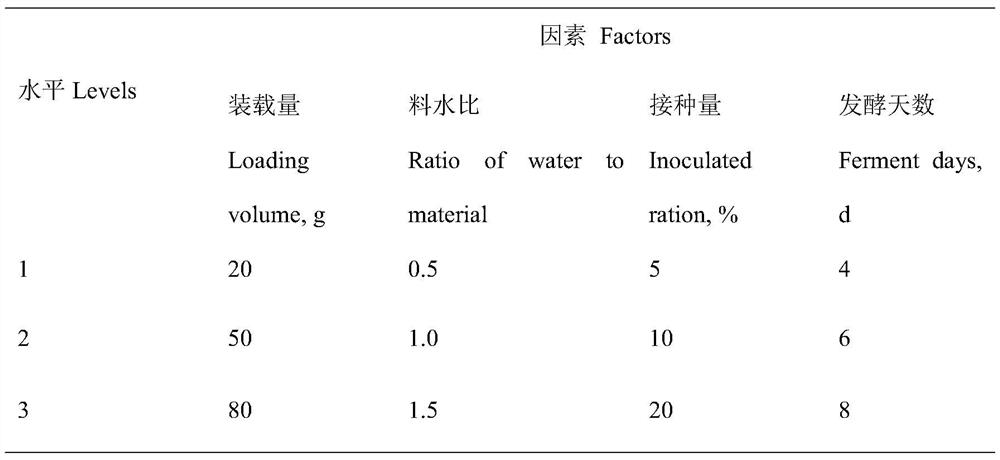

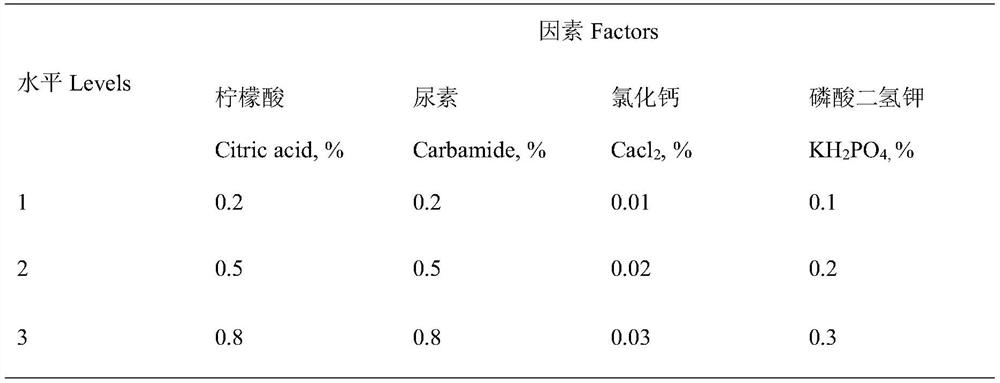

[0017] 1 Materials and methods

[0018] 1.1 Activation of bacteria and preparation of fermentation medium

[0019] Trichosporium fermentum CICC1368 was purchased from the China Industrial Microbiology Culture Collection Management Center, and Mortierella isabellina As 3.3410 was purchased from the Institute of Microbiology, Chinese Academy of Sciences. Saccharomyces cerevisiae YJZP01 and Rhodotorula graminearum H124 were kindly donated by the College of Science, Sichuan Agricultural University. Mortierella chrysogenum (M.isabellina As3.3410) was activated on the potato agar slant medium at 28°C for 7 days, and a single colony of Mortierella chrysogenum was inoculated into the potato liquid seed medium, shaken at 28°C and 180r / min. Bed culture 2d. The Mortierella chrysogenum spore liquid that is in the logarithmic growth phase of cultivating 2d is filtered with eight layers of sterile gauze to obtain the spore suspension. The yeast was cultured on the yeast glucose agar soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com