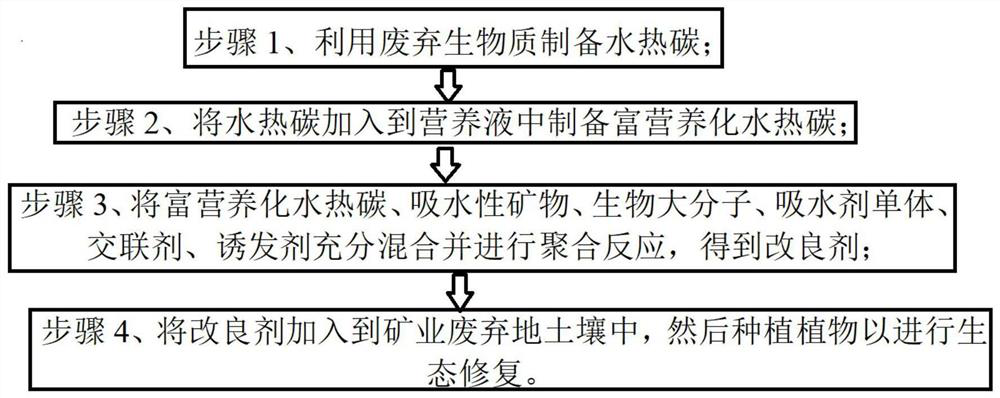

Ecological restoration method for mining waste land

An ecological restoration and wasteland technology, applied in the restoration of polluted soil, etc., can solve the problems of unsustainability, high cost, secondary pollution, etc., and achieve the effect of improving nutrients, low cost and good fertilizer efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] This embodiment carries out ecological restoration for the tailings of graphite ore dressing, and the process is as follows:

[0069] Step 1. Crushing straw, sawdust, fruit peel, bagasse, coconut shell, bamboo, fallen leaves and livestock manure, the particle size after crushing is 0.073mm; hydrothermally carbonizing the crushed waste biomass, and the crushed waste biomass The mass ratio to water is 1:1; the hydrothermal carbonization temperature is 160°C, and the hydrothermal carbonization time is 60 minutes; the hydrothermal carbonization product is subjected to solid-liquid separation to obtain solid hydrothermal carbon and hydrothermal carbon liquid;

[0070] Step 2. Add solid hydrothermal carbon to potassium dihydrogen phosphate solution with a mass concentration of 800mg / L for eutrophication. After eutrophication, perform solid-liquid separation and dry treatment. The drying temperature is 69°C to obtain eutrophication Hydrothermal carbon;

[0071] Step 3, fully ...

Embodiment 2

[0075] In this embodiment, ecological restoration is carried out for bauxite dressing tailings, and the process is as follows:

[0076] Step 1. Crushing straw, sawdust, fruit peel, bagasse, coconut shell, bamboo, fallen leaves and livestock manure, the particle size after crushing is 0.054mm; hydrothermally carbonizing the crushed waste biomass, and the crushed waste biomass The mass ratio to water is 1:5; the hydrothermal carbonization temperature is 320°C, and the hydrothermal carbonization time is 290 minutes; the hydrothermal carbonization product is subjected to solid-liquid separation to obtain solid hydrothermal carbon and hydrothermal carbon liquid;

[0077] Step 2. Add solid hydrothermal carbon to the potassium dihydrogen phosphate solution with a mass concentration of 1600mg / L for eutrophication. After eutrophication, perform solid-liquid separation and dry treatment. The drying temperature is 60°C to obtain eutrophication Hydrothermal carbon;

[0078] Step 3. Fully...

Embodiment 3

[0082] This embodiment carries out ecological restoration for magnesite ore dressing tailings, and the process is as follows:

[0083] Step 1. Crushing straw, sawdust, fruit peel, bagasse, coconut shell, bamboo, fallen leaves and livestock manure, the particle size after crushing is 0.054mm; hydrothermally carbonizing the crushed waste biomass, and the crushed waste biomass The mass ratio to water is 1:3; the hydrothermal carbonization temperature is 240°C, and the hydrothermal carbonization time is 180 minutes; the hydrothermal carbonization product is subjected to solid-liquid separation to obtain solid hydrothermal carbon and hydrothermal carbon liquid;

[0084] Step 2. Add solid hydrothermal carbon to the potassium dihydrogen phosphate solution with a mass concentration of 1200mg / L for eutrophication. After eutrophication, perform solid-liquid separation and dry treatment. The drying temperature is 55°C to obtain eutrophication Hydrothermal carbon;

[0085] Step 3. Fully ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com