Preparation method of manganese chloride tetrahydrate bulk drug

A technology of manganese chloride tetrahydrate and raw materials, applied in the direction of manganese halide, etc., can solve the problem of low safety of manganese chloride tetrahydrate and achieve high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

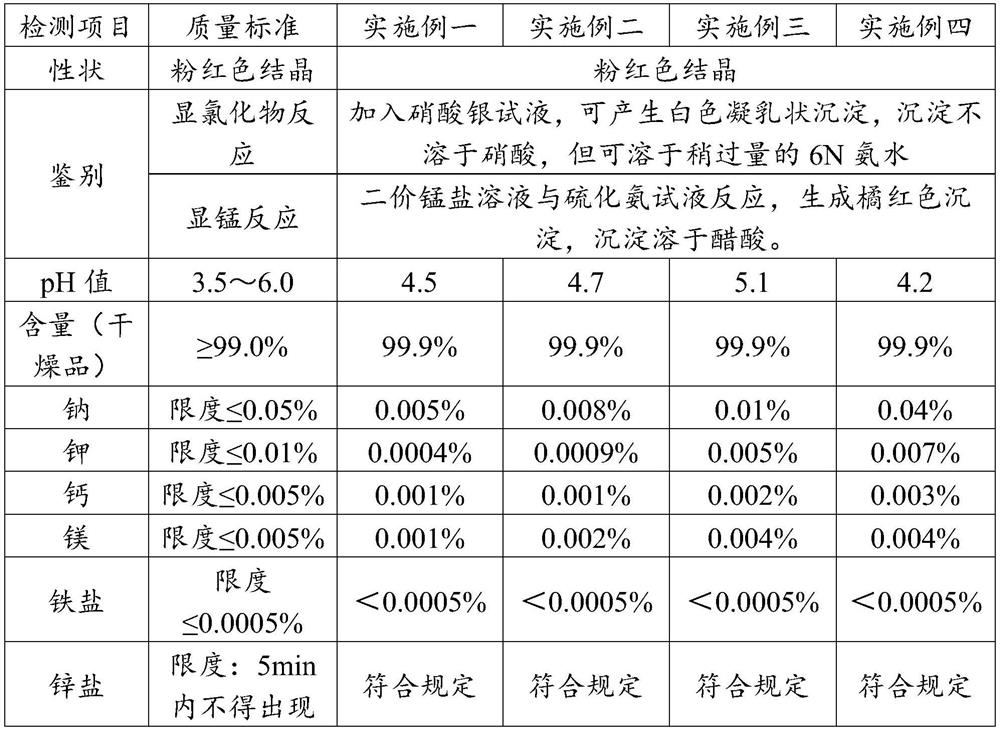

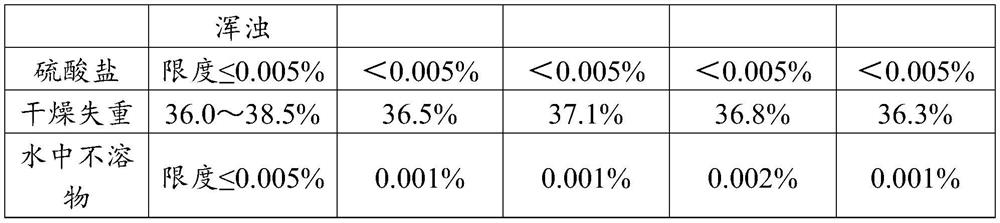

Examples

Embodiment

[0029] The embodiment of the present invention provides a kind of preparation method of manganese chloride tetrahydrate crude drug, and this preparation method comprises:

[0030] Mix manganese monoxide and water to obtain a suspension, the mass ratio of manganese monoxide to water is 1:3; in this example, manganese monoxide was purchased from Shanghai Aladdin Biochemical Technology Co., Ltd., with a content of ≥99.5% , the grade is M105457.

[0031] Slowly add hydrochloric acid dropwise into the suspension, the molar ratio of manganese monoxide and hydrochloric acid is 1: (1.8-2.0), to obtain the first reaction solution;

[0032] Heating the first reaction solution to 70-100°C for 3.5-4.5 hours, cooling to room temperature after heating to obtain the second reaction solution;

[0033] After adding food-grade diatomite to the second reaction solution and stirring, the first mixed solution is obtained. The quality of food-grade diatomite is 20% to 30% of the mass of manganese ...

Embodiment 1

[0056]Drop into 300.00g purified water and 100.00g manganese monoxide in the 1L four-neck flask (still) that is equipped with mechanical stirring device, open mechanical stirring device, make manganese monoxide and water mix, obtain suspension, then Add 256.98g of hydrochloric acid with a mass fraction of 37% into the constant pressure dropping funnel, control the molar ratio of manganese monoxide and hydrochloric acid to 1:1.85, slowly open the valve of the constant pressure dropping funnel, and let the hydrochloric acid drop slowly at room temperature In the four-necked flask (still), because the reaction exotherm is obvious, it is necessary to control the temperature in the four-necked flask (still) below 90°C. After the hydrochloric acid is dripped, record the temperature in the four-necked flask (still), and when the temperature in the four-necked flask (still) begins to drop, place the four-necked flask (still) in a preheated water bath with a water bath temperature of 10...

Embodiment 2

[0060] Drop into 300.00g purified water and 100.00g manganese monoxide in the 1L four-neck flask (still) that is equipped with mechanical stirring device, open mechanical stirring device, make manganese monoxide and water mix, obtain suspension, then Add 250.03g of hydrochloric acid with a mass fraction of 37% into the constant pressure dropping funnel, control the molar ratio of manganese monoxide and hydrochloric acid to 1:1.80, slowly open the valve of the constant pressure dropping funnel, and let the hydrochloric acid drop slowly at room temperature into a four-necked flask (still), because the reaction exotherm is obvious, so it is necessary to control the temperature in the four-necked flask (still) below 70°C. After the hydrochloric acid is dripped, record the temperature in the four-necked flask (still), and when the temperature in the four-necked flask (still) begins to drop, place the four-necked flask (still) in a preheated water bath with a water bath temperature o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com