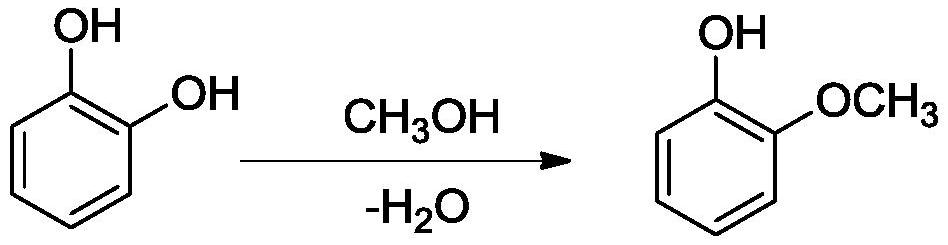

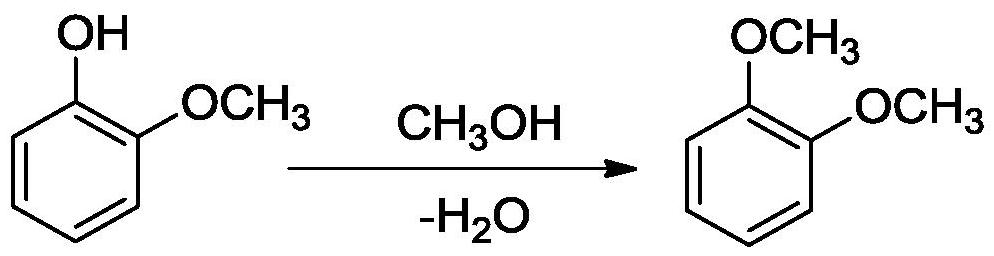

Preparation method of guaiacol

A technology of guaiacol and catechol, applied in ether preparation, chemical instruments and methods, dehydration of hydroxyl-containing compounds to prepare ether, etc., can solve the problems of reducing the service life of the catalyst, deactivating the catalyst, etc. effect of carbon, selectivity improvement, and service life improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

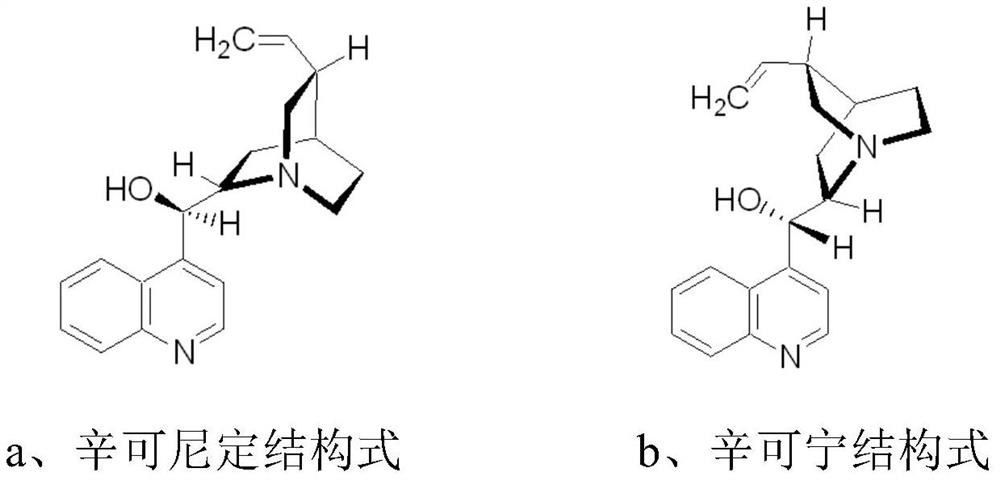

[0058] 72g of aluminum phosphate molecular sieve and 18g of cerium phosphate are mixed, extruded by a tablet machine and crushed to obtain solid particles of 20 mesh to 40 mesh. After mixing 8g of dimethyl dithiophosphate and 2g of cinchonidine, dissolve it in 90g of ethanol, and prepare an ethanol solution with an ethanol content of 90wt%, and add the prepared solid particles of 20 mesh to 40 mesh into the dissolved In the ethanol solution of dimethyl phosphorodithioate and cinchonidine, stir at 20°C for 12h, dry at 50°C for 8h, and bake at 200°C for 4h after the ethanol is completely evaporated to obtain the loaded stabilizer and modification Agent Catalyst-1.

Embodiment 2

[0060] 20g of alumina, 60g of silicoaluminophosphate molecular sieve and 5g of lanthanum phosphate are mixed, extruded with a tablet machine and crushed to obtain solid particles of 20-40 mesh. After mixing 5g of diethyl methyl phosphorothioate, 5g of diphenyl dithiophosphoric acid and 5g of cinchonine, they were dissolved in 135g of ethanol to prepare an ethanol solution with an ethanol content of 90wt%. The prepared 20 mesh to 40 Add the target solid particles to the ethanol solution dissolved in diethyl methyl phosphorothioate, diphenyl dithiophosphoric acid and cinchonine, stir at 60°C for 2 hours, dry at 80°C for 4 hours, and evaporate the ethanol completely Calcined at 180°C for 6 hours to obtain Catalyst-2 loaded with stabilizers and modifiers.

Embodiment 3

[0062] 70g of zirconium dioxide and 20g of neodymium phosphate are mixed, extruded by an extruder and crushed to obtain solid particles of 20 mesh to 40 mesh. After mixing 5g diethyl phosphorodithioate and 5g cinchonine, dissolve it in 115g ethanol, and prepare an ethanol solution with an ethanol content of 92wt%, and add the prepared solid particles of 20 mesh to 40 mesh In the ethanol solution of diethyl ester and cinchonine, stir at 35°C for 6 hours, dry at 60°C for 6 hours, and bake at 150°C for 8 hours after ethanol is completely evaporated to obtain Catalyst-3 loaded with stabilizers and modifiers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com