A Method for Assembling Ultrathin Ordered Conductive Polymer Films at the Liquid/Air Interface

A conductive polymer and film technology, which is applied in the field of assembling ultra-thin and ordered conductive polymer films at the liquid/air interface, can solve the problems of complex research, non-compliance with electron transport, and incomprehension, and achieves a simple preparation process, good and good performance. Order and crystallinity, easy operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

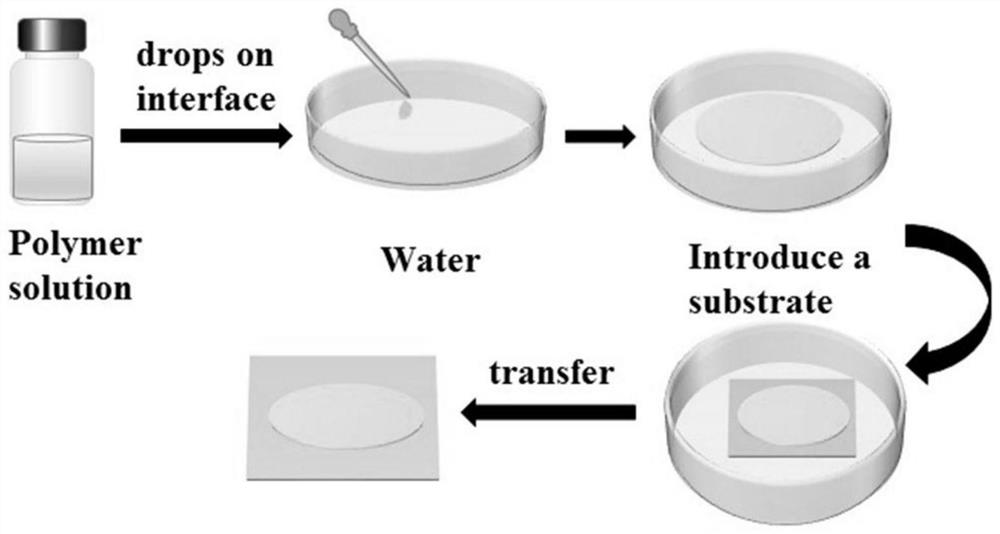

[0035] A method for assembling an ultra-thin ordered conductive polymer film at a liquid / air interface, specifically comprising the following steps:

[0036] (1) Accurately weigh 50 mg of poly-2-(2,5-dihexyl)phenyl)thiophene, then add 5 ml of chloroform solvent, vibrate and ultrasonically disperse until the polymer is completely dissolved to obtain a polymer chloroform solution;

[0037] (2) Use a polytetrafluoroethylene dropper to take an appropriate amount of solution, and quickly and gently drop it on the surface of a petri dish filled with deionized water;

[0038] (3) cutting a plurality of 2 × 2cm glass sheets as the target substrate;

[0039] (4) After the solvent is volatilized, a thin film is formed on the water surface, and then transferred to the target substrate for drying to obtain an ultra-thin and ordered eigenstate thin film material.

[0040] Schematic diagram of the method for assembling ultrathin ordered conductive polymer films through the liquid / air inter...

Embodiment 2

[0048] A method for assembling an ultra-thin ordered conductive polymer film at a liquid / air interface, specifically comprising the following steps:

[0049] (1) Accurately weigh 50 mg of poly-2-(2,5-dioctyl)phenyl)thiophene, then add 5 ml of dichloromethane solvent, vibrate and ultrasonically disperse until the polymer is completely dissolved to obtain a polymer solution;

[0050] (2) Use a polytetrafluoroethylene dropper to take an appropriate amount of solution, and quickly and gently drop it on the surface of a petri dish filled with deionized water;

[0051] (3) Cutting a plurality of 2×2cm silicon wafers as the target substrate;

[0052] (4) After the solvent is volatilized, a thin film is formed on the water surface, and then transferred to the target substrate for drying to obtain an ultra-thin and ordered eigenstate thin film material.

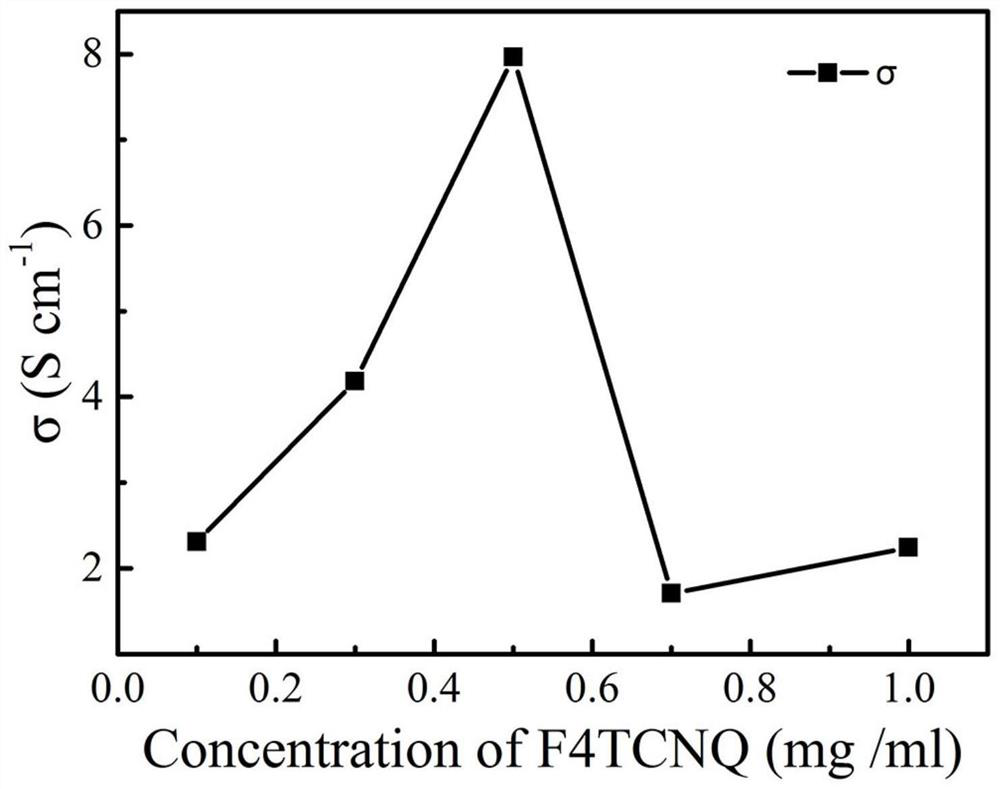

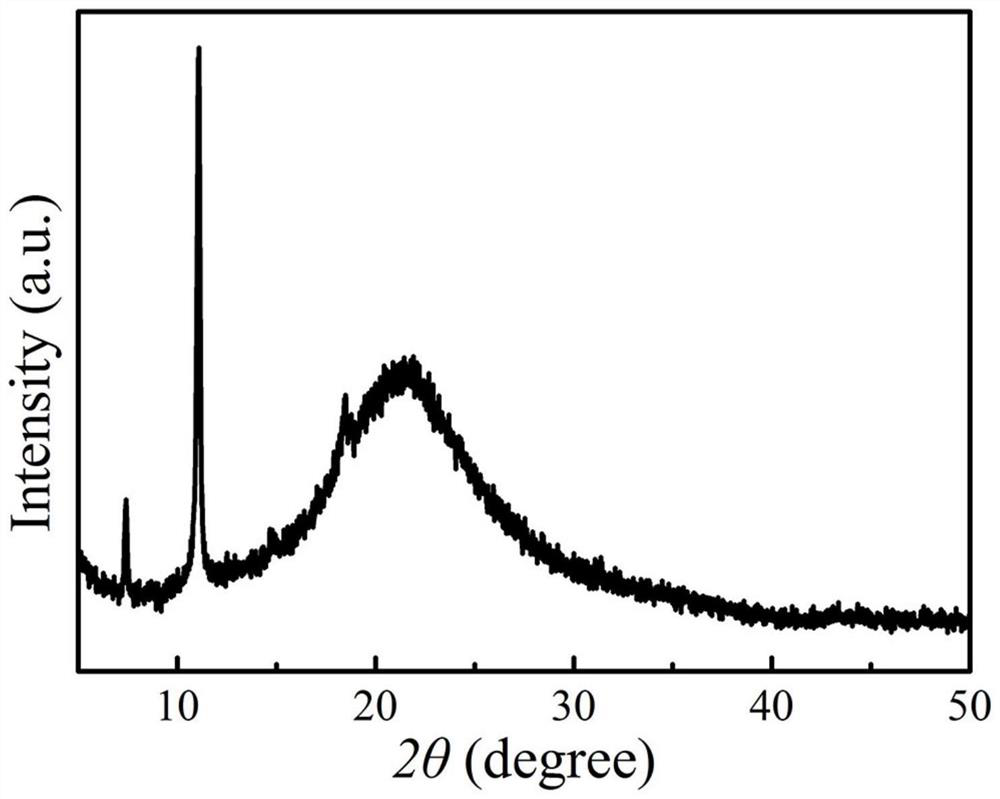

[0053] Due to the extremely poor conductivity of the obtained intrinsic state films, it is necessary to introduce dopants to improv...

Embodiment 3

[0057] A method for assembling an ultra-thin ordered conductive polymer film at a liquid / air interface, specifically comprising the following steps:

[0058] (1) Accurately weigh 50 mg of poly-2-(2,5-di-dodecyl)phenyl)thiophene, then add 5 ml of chlorobenzene solvent, vibrate and ultrasonically disperse until the polymer is completely dissolved to obtain a polymer solution;

[0059] (2) Use a polytetrafluoroethylene dropper to take an appropriate amount of solution, and quickly and gently drop it on the surface of a petri dish filled with deionized water;

[0060] (3) Cut out multiple pieces of 2×2cm polypropylene sheets as the target substrate;

[0061] (4) After the solvent is volatilized, a thin film is formed on the water surface, and then transferred to the target substrate for drying to obtain an ultra-thin and ordered eigenstate thin film material.

[0062] Due to the extremely poor conductivity of the obtained intrinsic state films, it is necessary to introduce dopant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com