Tar residue treatment method and treatment system

A processing method and processing system technology, applied in the field of tar residue processing method and processing system, can solve the problems affecting the accuracy of transportation and coal blending, environmental protection, sticky and hardened irritating odor, etc., and achieve high degree of automation, transportation Convenience, the effect of increasing tar income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

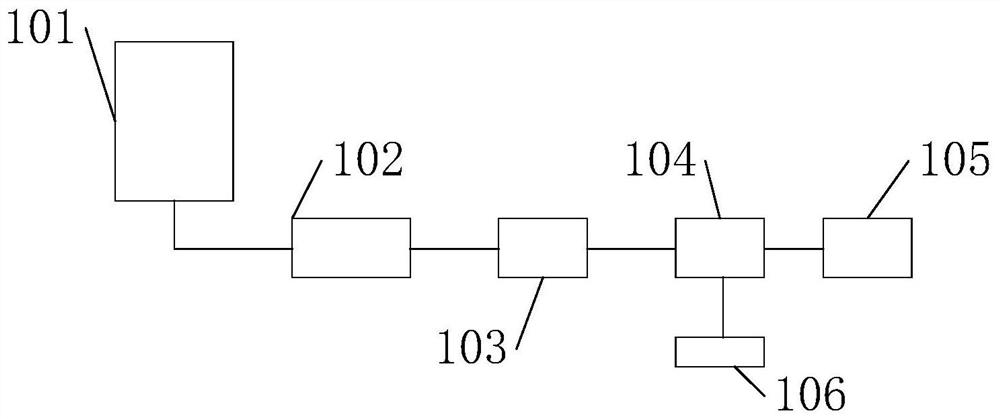

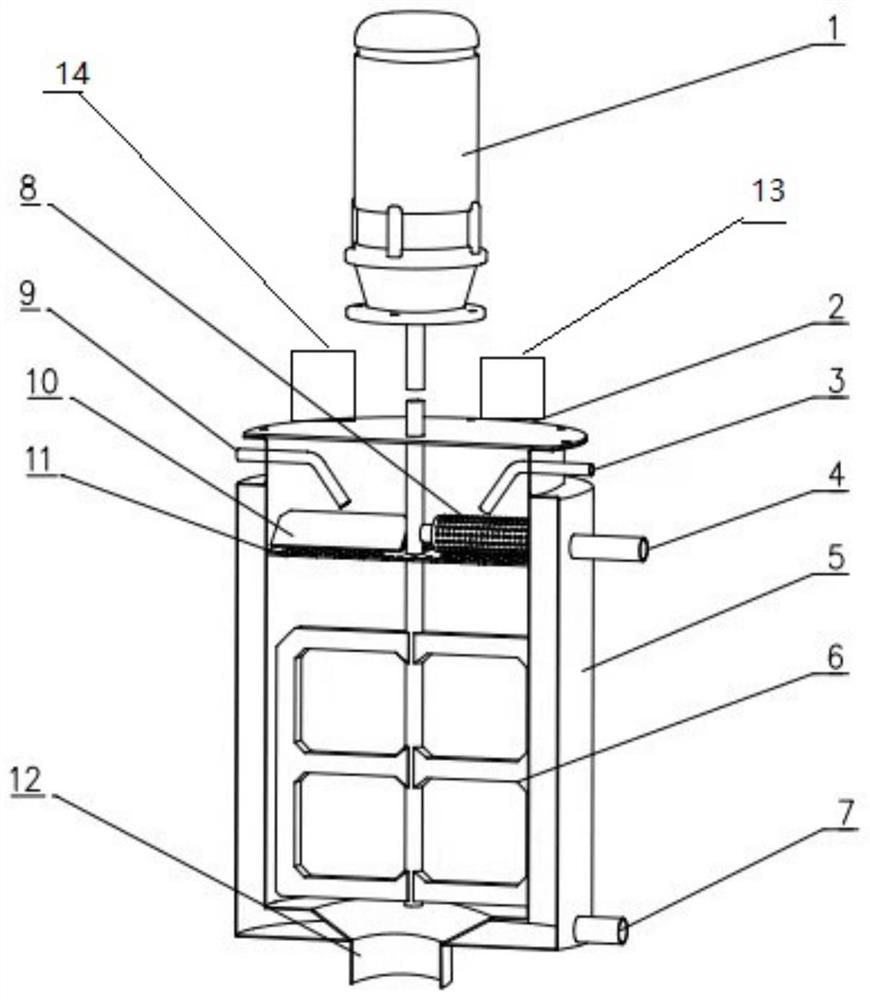

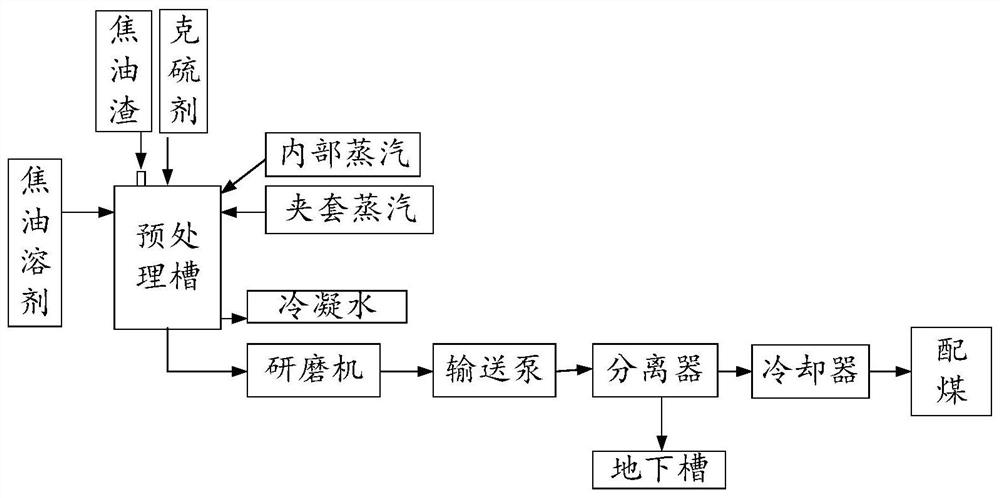

[0095] A treatment system for tar residue, comprising a pretreatment tank 101 and a separator 104; the pretreatment tank 101 includes a pretreatment tank body and a jacket 5 arranged outside the body; the pretreatment tank 101 is provided with A reduction motor 1, the output end of the reduction motor 1 is connected with a rotating shaft, the rotating shaft is provided with an agitator 6, and the agitator 6 is arranged in the pretreatment tank body; There is a sieve plate 11 above the agitator 6, the rotating shaft rotates through the sieve plate 11, and a tar residue scraper 10 and a tar residue scraper 10 located above the sieve plate are oppositely arranged on the side wall of the rotating shaft along the circumferential direction. Liquid wheel 8; the sieve plate 11 is horizontally arranged, and is detachably connected with the inner wall of the pretreatment tank body; the sieve hole of the sieve plate 11 is a circular hole with a diameter of 10mm, and the distance between t...

Embodiment 2

[0103] A treatment system for tar residue, except that there are two steam pipes with a diameter of 30 mm, and other conditions are the same as in Example 1.

[0104] A treatment method for tar residue, using the above-mentioned treatment system for tar residue, comprising the following steps:

[0105]Take 1.5 tons of oil residue from the mechanized clarification tank in the coking plant and enter the pretreatment tank through the feed port, add 200kg of diesel oil and 30kg of sulfur agent in the pretreatment tank, and insert the steam pipe evenly into the pretreatment tank to keep the tank at 70 °C, fully Stop stirring well, pump the hot tar slurry into the separator, flow the separated oil and water into the underground tank (tar tank) from the bottom, send the separated tar residue into the cooler, and dry the tar residue out of the cooler to powder Send into the coal blending system and blend the coal into coke; the gram of sulfur agent is the same as in Example 1.

Embodiment 3

[0107] A treatment system for tar residue, except that the diameter of the steam pipe is 30mm, other conditions are the same as in Example 1.

[0108] A treatment method for tar residue, using the above-mentioned treatment system for tar residue, comprising the following steps:

[0109] Take 1 ton of tar residue produced in the process of tar fractionation and refinement through the pretreatment tank at the feed inlet, add 300 kg of phenol oil and 200 kg of sulfur agent, and insert the steam pipe vertically and evenly into the pretreatment tank to keep 65 ℃, stir well without stopping, use a pump to pump the hot tar slurry into the separator, flow the separated oil and water into the underground tank (tar tank) from the bottom, send the separated tar residue into the cooler, and put the separated oil and water into the cooler. The dry powder of the tar residue is sent to the coal blending system for coal blending to make coke; the gram sulfur agent is the same as in Example 1....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com