Comprehensive recovery method for uranium-containing low-grade polymetallic ores

A polymetallic ore and recovery method technology, applied in comprehensive recovery of uranium-containing low-grade polymetallic ore, green and high-efficiency beneficiation comprehensive recovery of uranium-containing low-grade polymetallic ore, can solve the problem of high gravity separation cost, corrosion of flotation equipment and pipelines , Low recovery rate of useful elements and other problems, to achieve the effect of reducing the amount of sulfuric acid, reducing the content of carbonate, and improving the recovery rate of gravity separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

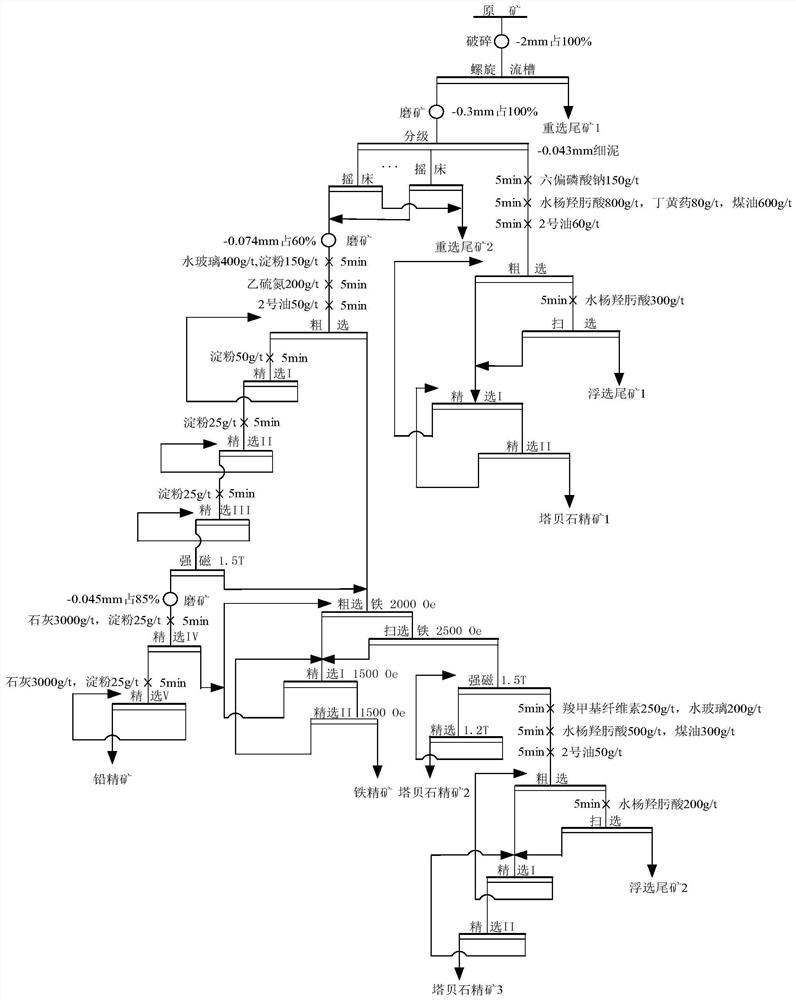

[0072] A low-grade multi-metal uranium mine in Shaanxi is mainly composed of heavy crystal stone, square album, long stone, quartz, yellow iron ore, square lead ore, stone, corner, black, green curtain, pomegranate stone, magnetite , Zircon, apatite, asphalt uranium, tower stone and other mineral composition, mainly useful minerals for tower stone, square lead mine, magnetite, etc., uranium product is 0.016%, the bony is 0.017%, lead grade It is 0.54%, and the iron is 4.04%.

[0073] (1) First, the ore is fine to -5 mm, and the spiral chute is sorted by a spiral chute to obtain a coarse concentrate and reselect tailings 1.

[0074] (2) The coarse colon obtained in (1) is retranslated to the coarse concentrate to be less than 0.6 mm, and the ore after the mill is divided into five grain grains, respectively, which is -0.6 ~ + 0.4mm, -0.4 ~ + 0.2mm, -0.2 ~ + 0.074 mm, -0.074 ~ + 0.043 mm, -0.043mm. The first four grades were re-selected by shaking by shaker, and the four reselection...

Embodiment 2

[0086] A low-grade multi-metal uranium mine in Shaanxi is mainly composed of heavy crystal stone, square album, long stone, quartz, yellow iron ore, square lead ore, stone, corner, black, green curtain, pomegranate stone, magnetite , Zircon, apatite, asphalt uranium, tower stone and other mineral composition, mainly useful minerals for tower stone, square lead mine, magnetite, etc., uranium product is 0.016%, the bony is 0.017%, lead grade It is 0.54%, and the iron is 4.04%.

[0087] (1) First of all, the ore is fine to -3.5 mm, and the spiral chute is sorted by a spiral chute to obtain a coarse concentrate and reselect tailings 1.

[0088] (2) The spiral chute obtained in (1) is redistributed to the coarse concentrate to be less than 0.4 mm, and the ore after the mill is divided into four grain grades, respectively, which is -0.4 ~ + 0.2mm, -0.2 ~ +. 0.074 mm, -0.074 ~ + 0.043 mm, -0.043mm. The top three grades were reselected by shaking by shaker, and the three reselection conce...

Embodiment 3

[0101] A low-grade multi-metal uranium mine in Shaanxi is mainly composed of heavy crystal stone, square album, long stone, quartz, yellow iron ore, square lead ore, stone, corner, black, green curtain, pomegranate stone, magnetite , Zircon, apatite, asphalt uranium, tower stone and other mineral composition, mainly useful minerals for tower stone, square lead mine, magnetite, etc., uranium product is 0.016%, the bony is 0.017%, lead grade It is 0.54%, and the iron is 4.04%.

[0102] (1) First of all, the ore is subjected to the ore, and the spiral chute is sorted by the spiral chute to obtain a coarse column and reselect tailings 1.

[0103] (2) Re-selection of the spiral chute obtained in (1) is reselected to the fine concentration of less than 0.3 mm, divide the ore after the mill is divided into three grain grades, respectively - 0.3 ~ + 0.15mm, -0.15 ~ + 0.074 mm, -0.074 ~ + 0.043 mm, -0.043mm. The first two grades were reselected with a shaker, and the two reselection concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com