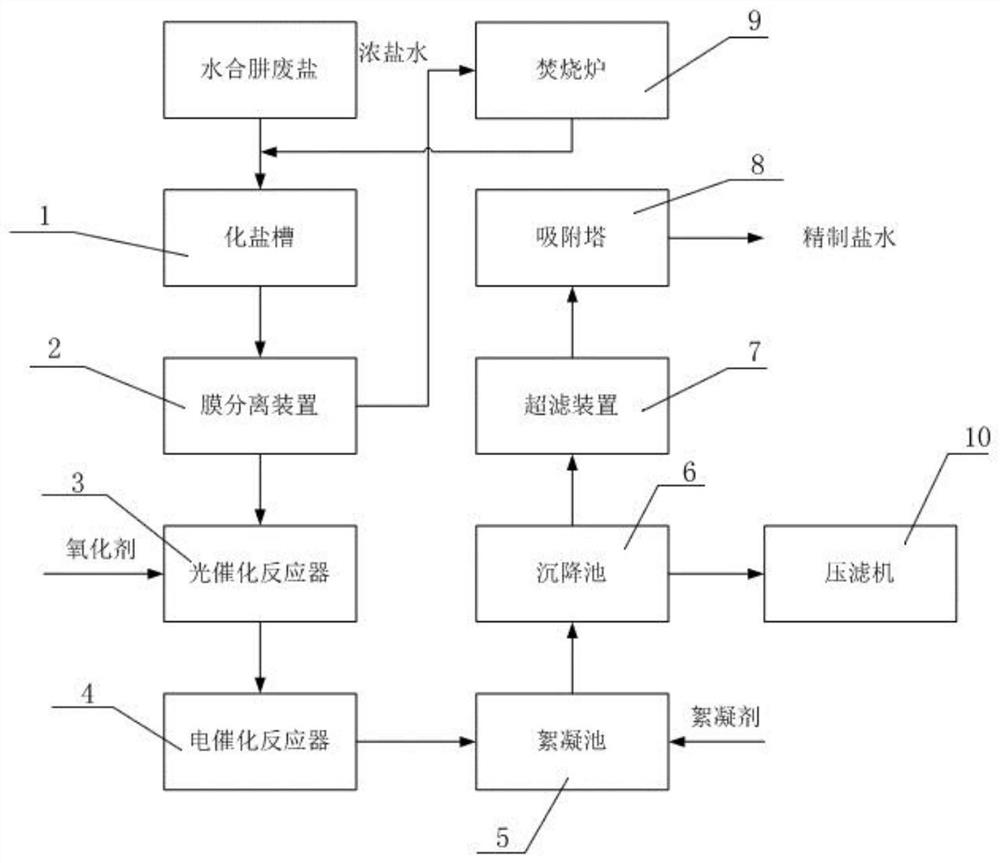

Comprehensive treatment method and system for hydrazine hydrate waste salt

A comprehensive treatment, hydrazine hydrate technology, applied in the comprehensive treatment method and system field of hydrazine hydrate waste salt, can solve the problems of high treatment cost, only solid waste treatment, and specific requirements for the treatment site, and achieve high economic and social benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032]1) Take 10kg of hydrazine hydrate by-product salt, prepare a solution with NaCl content of 310g / L with pure water, measure its total organic carbon TOC as 40mg / L, and total nitrogen TN as 20mg / L.

[0033] 2) Adjust the pH of the prepared brine to 8 with 1mol / L HCl, and then perform nanofiltration membrane separation, control the membrane inlet pressure to 3.5MPa, and the temperature to 20°C. According to the nanofiltration membrane, the recovery rate of light liquid is 85%. When the nanofiltration membrane separation is stopped. The measured total organic carbon TOC of the nanofiltration membrane dilute liquid is 15.83mg / L, and the total nitrogen TN is 8.17mg / L.

[0034] 3) Use 1mol / L of HCl to adjust the pH of the nanofiltration membrane light liquid to 5, then carry out photocatalytic oxidation, the ultraviolet wavelength is 222nm, the flow rate of water is controlled to be 0.5m / s, the catalyst is titanium dioxide, the oxidant is oxygen, at temperature The reaction wa...

example 2

[0042] 1) Take 10kg of by-product salt obtained on the glyphosate production route, and prepare a solution with a NaCl content of 310g / L. The total organic carbon TOC is 150mg / L, and the total nitrogen TN is 80mg / L.

[0043] 2) Use 1mol / L NaOH to adjust the pH of the prepared brine to 7.5, and then perform nanofiltration membrane separation, control the membrane inlet pressure to 3.2MPa, and the temperature to 25°C. According to the nanofiltration membrane, the recovery rate of light liquid is 90%. When the nanofiltration membrane separation is stopped. The measured total organic carbon TOC of the nanofiltration membrane dilute liquid is 40.83mg / L, and the total nitrogen TN is 15.17mg / L.

[0044] 3) Adjust the pH of the nanofiltration membrane light liquid to 6 with 1mol / L HCl, and then carry out photocatalytic oxidation, the ultraviolet wavelength is 222nm, and the influent flow rate is controlled to be 0.7m / s. The catalyst is titanium dioxide, and the oxidant is ozone. Afte...

Embodiment 3

[0052] 1) Take 50kg of hydrazine hydrate by-product salt, prepare a solution with NaCl content of 300g / L with pure water, measure its total organic carbon TOC to be 52.5mg / L, and total nitrogen TN to be 23mg / L. 1mol / L hydrochloric acid to adjust the pH to 5;

[0053] 2) Carry out nanofiltration membrane separation, control membrane inlet pressure to be 2.5MPa, temperature be 18 ℃, stop nanofiltration membrane separation when the recovery rate of light liquid according to nanofiltration membrane is 85%.

[0054] 3) adjust the pH of the nanofiltration membrane light liquid to 4 with 1mol / L of HCl, and then carry out photocatalytic oxidation, the ultraviolet wavelength is 280nm, the flow rate of the water inflow is controlled to be 0.2m / s, the catalyst is manganese dioxide, and the oxidizing agent is ozone. Filtration was performed after circulating the reaction at a temperature of 18° C. for 5 h.

[0055] 4) After adjusting the pH of the above-mentioned filtered clear liquid to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com