Core-shell structure positive electrode material and preparation method thereof

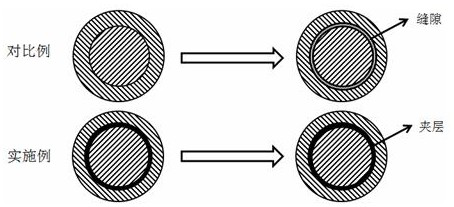

A cathode material and a core-shell structure technology, applied in the field of core-shell structure cathode materials and their preparation, can solve the problems of poor material cycle performance, hinder lithium ion conduction, unfavorable long-life cycle stability, etc., and facilitate large-scale production. , Overcome the effect of easy moisture absorption and obvious cost-effective advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

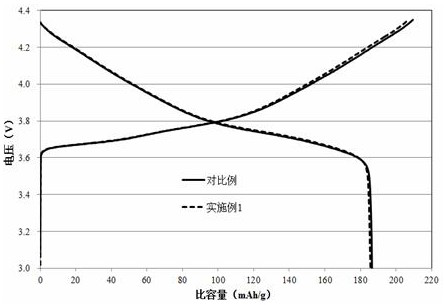

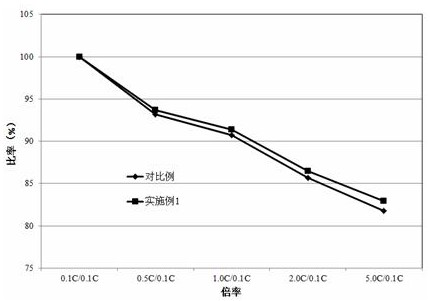

Embodiment 1

[0043] 1) Weigh a certain amount of nickel sulfate, cobalt sulfate, and manganese sulfate in a molar ratio of Ni:Co:Mn=8:1:1 and 2:1:1 and dissolve them in deionized water to obtain solution A and solution B .

[0044] 2) dissolving zirconium sulfate in water to obtain zirconium sulfate solution, wherein the Zr ion concentration is 1mol / L.

[0045] 3) 10L of ammonia solution was added to the 100L reaction kettle as the bottom liquid, and the protective gas nitrogen was introduced, and the temperature of the reaction kettle was controlled at 55° C., and the stirring speed was 600 r / min. Pump solution A, 5mol / L sodium hydroxide alkali solution and 10mol / L ammonia water complexing agent solution into the reaction kettle at the same time, control the pH of the reaction system to maintain at 11.6, and adjust the ammonium root concentration to 4-6g / L , when the average particle size of the core precursor reaches 7 μm, the reaction is stopped and the mixed solution C is obtained.

...

Embodiment 2

[0053] 1) Weigh a certain amount of nickel sulfate, cobalt sulfate, and manganese sulfate in a molar ratio of Ni:Co:Mn=8:1:1 and 2:1:1 and dissolve them in deionized water to obtain solution A and solution B .

[0054] 2) dissolving zirconium sulfate in water to obtain zirconium sulfate solution, wherein the Zr ion concentration is 1mol / L.

[0055] 3) 10L of ammonia solution was added to the 100L reaction kettle as the bottom liquid, and the protective gas nitrogen was introduced, and the temperature of the reaction kettle was controlled at 55° C., and the stirring speed was 600 r / min. Pump solution A, 5mol / L sodium hydroxide alkali solution and 10mol / L ammonia water complexing agent solution into the reaction kettle at the same time, control the pH of the reaction system to maintain at 11.6, and adjust the ammonium root concentration to 4-6g / L , when the average particle size of the core precursor reaches 7 μm, the reaction is stopped and the mixed solution C is obtained.

...

Embodiment 3

[0061] 1) Weigh a certain amount of nickel chloride, cobalt chloride, and manganese chloride in the ratio of Ni:Co:Mn=9:0.5:0.5 and 4:2:4 in molar ratio and dissolve them in deionized water to obtain solution A and solution B.

[0062] 2) Dissolving aluminum nitrate in water to obtain an aluminum nitrate solution, wherein the concentration of Al ions is 1.5 mol / L.

[0063] 3) 10L of ammonium carbonate solution was added to the 100L reactor as the bottom liquid, and the protective gas nitrogen was introduced, and the temperature of the reactor was controlled at 55°C, and the stirring speed was 550r / min. Pump solution A, 5mol / L potassium hydroxide alkali solution and 10mol / L ammonium carbonate complexing agent solution into the reaction kettle at the same time, control the pH of the reaction system to maintain at 11.8, and adjust the ammonium root concentration to 4-6g / L L, the mixture C was obtained after the reaction was stopped when the average particle size of the core prec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com