Royal jelly and preparation method thereof

A technology of royal jelly and jelly stock solution, applied in food science, food preservation, alcoholic food ingredients, etc., can solve the problems affecting the health care and nutritional function of royal jelly, the decomposition of royal jelly water-soluble protein, and the poor stability of water-soluble protein, etc., to reduce the possibility of Unique, simple steps, and easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

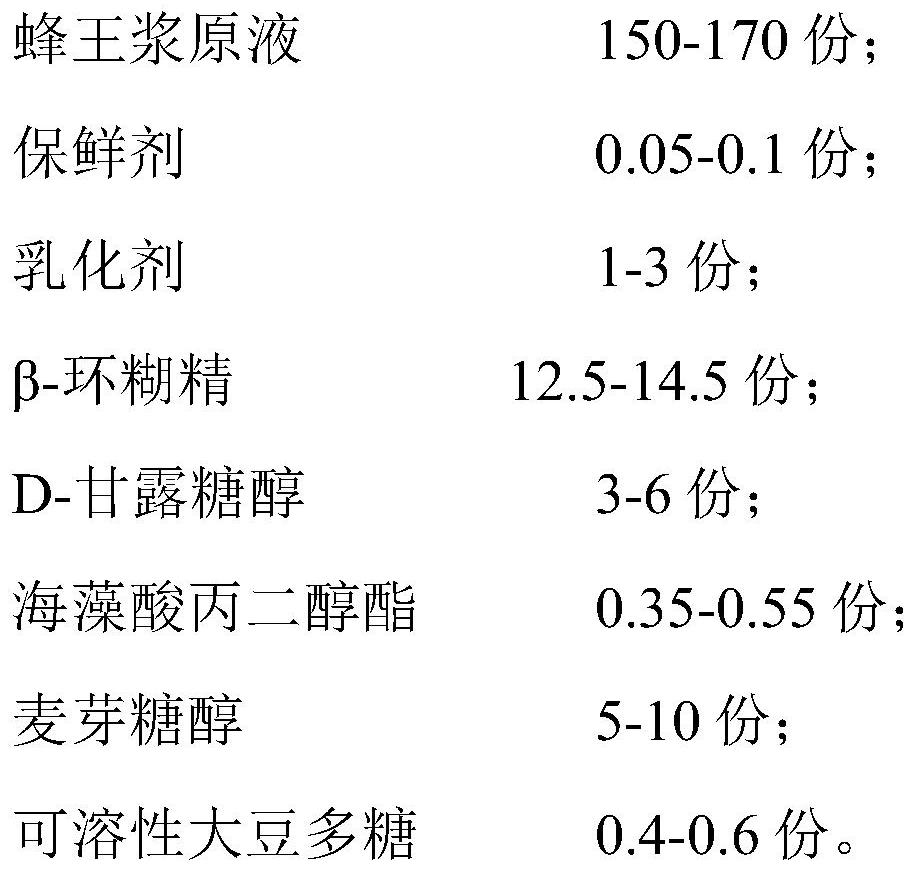

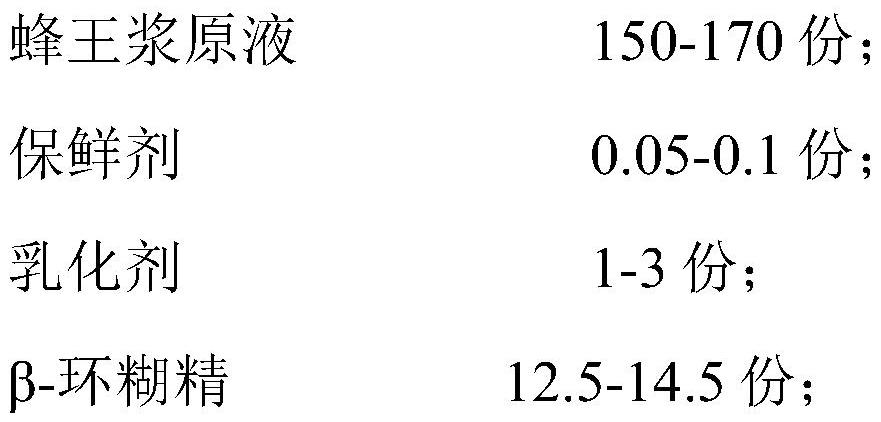

[0047] A preparation method of royal jelly, comprising the following steps:

[0048] S1. 0.1kg preservative (calcium lactate is 0.0207kg, honey is 0.0345kg, cornstarch is 0.0276kg, chitosan is 0.017kg), 3kg D-mannitol, 0.55kg propylene glycol alginate, 5kg maltitol 1. Mix 0.6kg soluble soybean polysaccharide with 30kg water, stir for 10min, then add 1kg phospholipid, continue stirring for 20min at 40°C, then cool to room temperature, then mix with 150kg royal jelly stock solution, continue stirring for 1h to obtain royal jelly mixture ;

[0049] S2. Adjust the pH of the royal jelly mixture to 8.7 with a sodium hydroxide solution with a concentration of 1 mol / L, then add 14.5 kg of β-cyclodextrin at a temperature of 27° C., and stir for 5 hours;

[0050] S3. Filter the product obtained in step S2 through a 100-mesh sieve, then pre-freeze at -30°C for 1 hour, and then vacuum freeze-dry for 2 hours at a vacuum of 100 Pa to obtain the product.

Embodiment 2

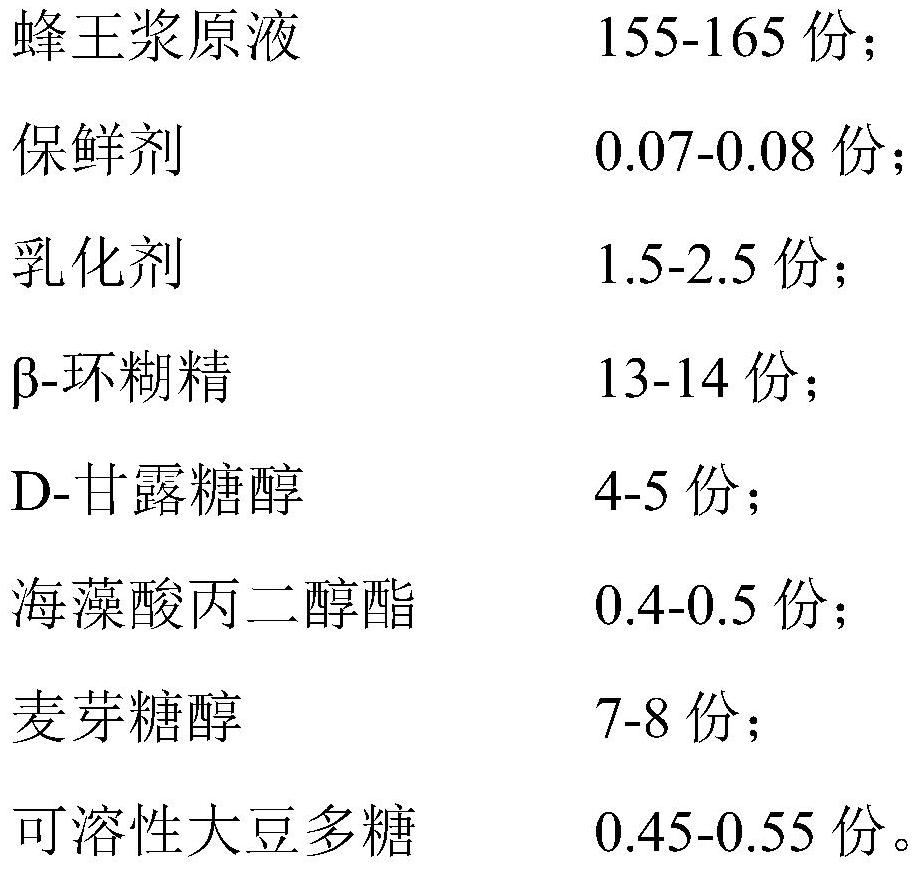

[0052] A preparation method of royal jelly, comprising the following steps:

[0053] S1. 0.075kg preservative (calcium lactate is 0.0159kg, honey is 0.0227kg, cornstarch is 0.0227kg, chitosan is 0.0137kg), 4.5kg D-mannitol, 0.45kg propylene glycol alginate, 7.5kg Mix maltitol, 0.5kg soluble soybean polysaccharide and 35kg water, stir for 12.5min, then add 2kg propylene glycol, continue stirring for 25min at 45°C, then cool to room temperature, then mix with 160kg royal jelly stock solution, continue stirring for 1.5h, Obtain royal jelly mixture;

[0054] S2. Use a sodium hydroxide solution with a concentration of 1.1 mol / L to adjust the pH of the royal jelly mixture to 8.8, then add 13.5 kg of β-cyclodextrin at a temperature of 28.5° C., and stir for 5.5 hours;

[0055] S3. Filter the product obtained in step S2 through a mesh sieve with a pore size of 110 meshes, then pre-freeze at -22.5°C for 2 hours, and vacuum freeze-dry for 3.5 hours at a vacuum of 140 Pa to obtain the p...

Embodiment 3

[0057] A preparation method of royal jelly, comprising the following steps:

[0058] S1. Put 0.05kg preservative (calcium lactate is 0.0108kg, honey is 0.0135kg, cornstarch is 0.0162kg, chitosan is 0.0095kg), 6kg D-mannitol, 0.35kg propylene glycol alginate, 10kg maltitol 1. Mix 0.4kg of soluble soybean polysaccharide with 40kg of water, stir for 15min, then add 3kg of lauric acid, continue to stir for 30min at a temperature of 50°C, then cool to room temperature, then mix with 170kg of royal jelly stock solution, continue to stir for 2h to obtain royal jelly mixture liquid;

[0059] S2. Adjust the pH of the royal jelly mixture to 8.9 with a sodium hydroxide solution with a concentration of 1.2 mol / L, then add 12.5 kg of β-cyclodextrin at a temperature of 30° C., and stir for 6 hours;

[0060] S3. Filter the product obtained in step S2 through a 120-mesh sieve, then pre-freeze at -15°C for 3 hours, and then vacuum freeze-dry for 5 hours at a vacuum of 180 Pa to obtain the pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com