Silk fibroin 3D printing bio-ink and application thereof

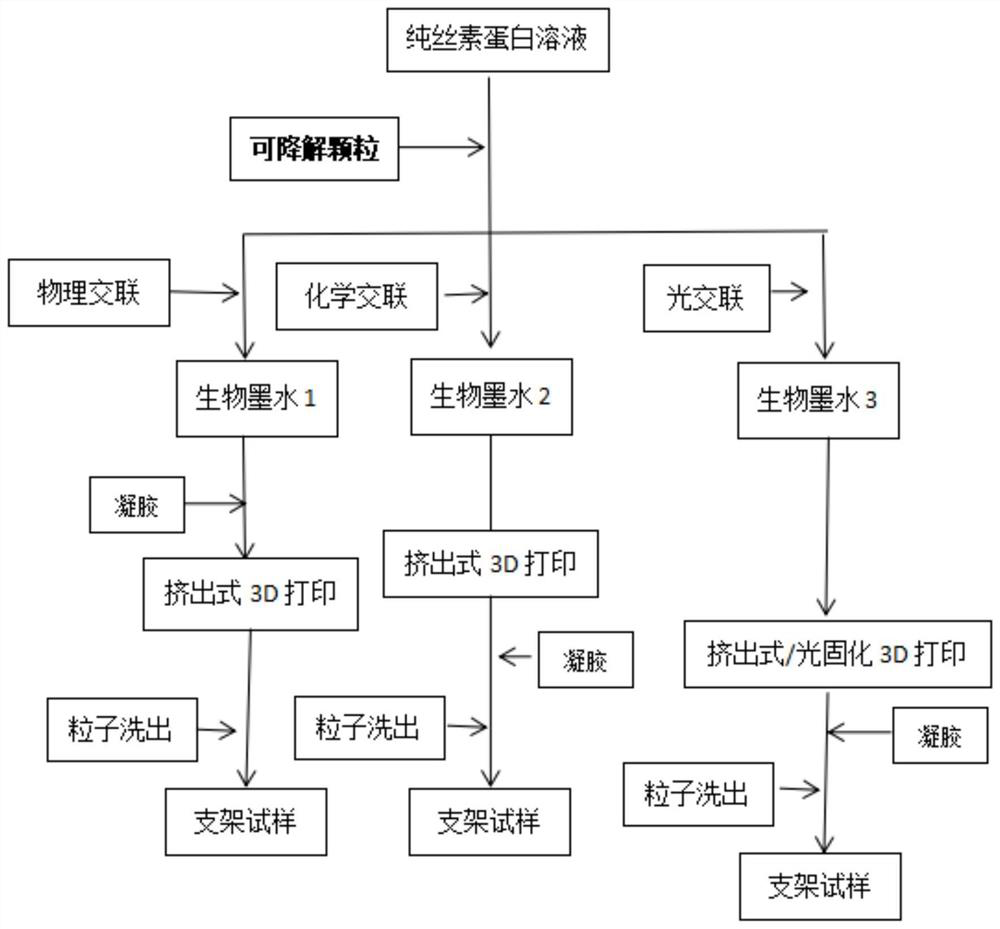

A 3D printing and silk fibroin technology, applied in medical science, prosthesis, additive processing, etc., can solve problems such as the dependence of microscopic pore size and porosity, affecting cell adhesion and growth, and difficult to process three-dimensional scaffolds. Achieve good biocompatibility and mechanical properties, improve material exchange efficiency, and achieve personalized regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The preparation of embodiment 1 silk fibroin solution

[0065] (1) Silk degumming method: Measure 12L of pure water and pour it into the degumming pot, heat the pure water, weigh 25.44g of anhydrous Na 2 CO 3 , when the water is about to boil add. Weigh 30g raw silk, wait for anhydrous Na 2 CO 3 After fully dissolving in boiling water, add and cook for 30 minutes. After cooking, take it out, wash it with 2L of pure water repeatedly for 3 times, and put it in a fume hood to dry;

[0066] (2) Silk dissolving method: Weigh 80.75g lithium bromide (99.9%) in a 500mL beaker, set the volume to a 100mL volumetric flask (9.3M), weigh 5 parts of degummed silk in step (1), each 5g Put it in a 50mL beaker, pour 20mL lithium bromide solution into each beaker, place it in a 60°C oven, shake the beaker every 1 hour, and take it out after 4 hours;

[0067] (3) Silk fibroin solution dialysis method: cut out 5 sections of dialysis bag, and the molecular weight cut-off of the dialys...

Embodiment 2

[0070] Embodiment 2: Preparation of photosensitive silk fibroin

[0071] (1) Add 424mM GMA solution to the silk fibroin solution obtained in step (2) of Example 1, mix well, and react at 60° C. for 3 hours at a speed of 30 rpm to produce a high-yield reaction.

[0072] (2) After filtering, use a dialysis bag with a molecular weight cut-off of 12-14kDa to dialyze for 4 days, replace the deionized water 6 times a day, then place it in a -80°C refrigerator overnight, freeze-dry it and place it at -4°C for future use. use.

Embodiment 3

[0073] Example 3: Cell Culture

[0074] (1) Primary acquisition of BMSCs (Bone Marrow Mesenchymal Stem Cells)

[0075] Pour ether into cotton to anesthetize SD rats, kill them by necking, soak the dead bodies of rats in 75% ethanol for disinfection; soak them for 30 minutes, take them out and put them in the ultra-clean workbench to start the experiment, cut the skin of the legs of the rats and muscles, remove the complete tibia and femur, soak in PBS solution containing 10% double antibody for 5-10 minutes, take it out, soak it in PBS solution containing 5% double antibody for 5-10 minutes, and finally soak it in In PBS solution containing 1% double antibody for 5-10 minutes; cut off both ends of the tibia and femur to expose the bone marrow cavity, insert 1mL filled with complete medium into the end of the bone marrow cavity, and slowly push the syringe. Place the centrifuge tube under the other end of the bone to collect the flushed fluid. After all flushing is completed,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com