Double-mold casting machine for transverse core-pulling pouring of aluminum piston blank and using method of double-mold casting machine

A casting machine and piston technology, applied in pistons, casting workshops, casting equipment, etc., can solve the problems of slow cooling of the head of the piston rough, coarse grain structure, low production efficiency, etc., to avoid pores, trachoma, and fine grain structure , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

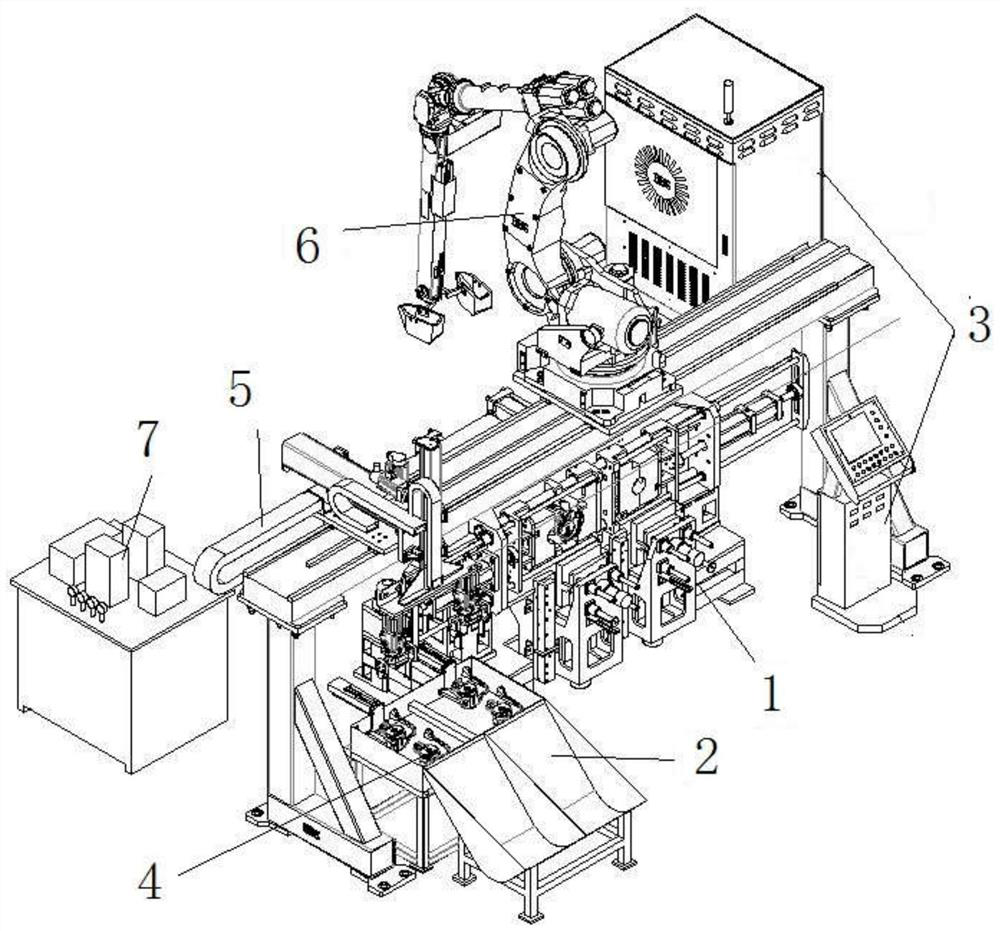

[0040] Such as Figure 1-8 As shown, this embodiment provides a double-mode casting machine for casting aluminum piston blanks by lateral core pulling, including a pouring system 1, a truss picking manipulator 5, a joint pouring robot 6, a hydraulic system 7, an electrical operating system 3, and a quenching and cooling box 2, of which,

[0041]The truss pick-up manipulator 5 is set above the pouring system 1, and the joint pouring robot 6 is set on the truss pick-up manipulator 5. The joint pouring robot 6 picks up molten aluminum and pours it into the pouring system 1. A quenching cooling box 2 is set under one side of the truss pick-up manipulator 5. The truss pick-up manipulator 5 clamps the piston blank 4 poured by the pouring system to the quenching cooling box 2, the pouring system 1 is connected to the hydraulic system 7, and the hydraulic system, the truss pick-up manipulator and the joint pouring robot are all connected to the electrical operating system.

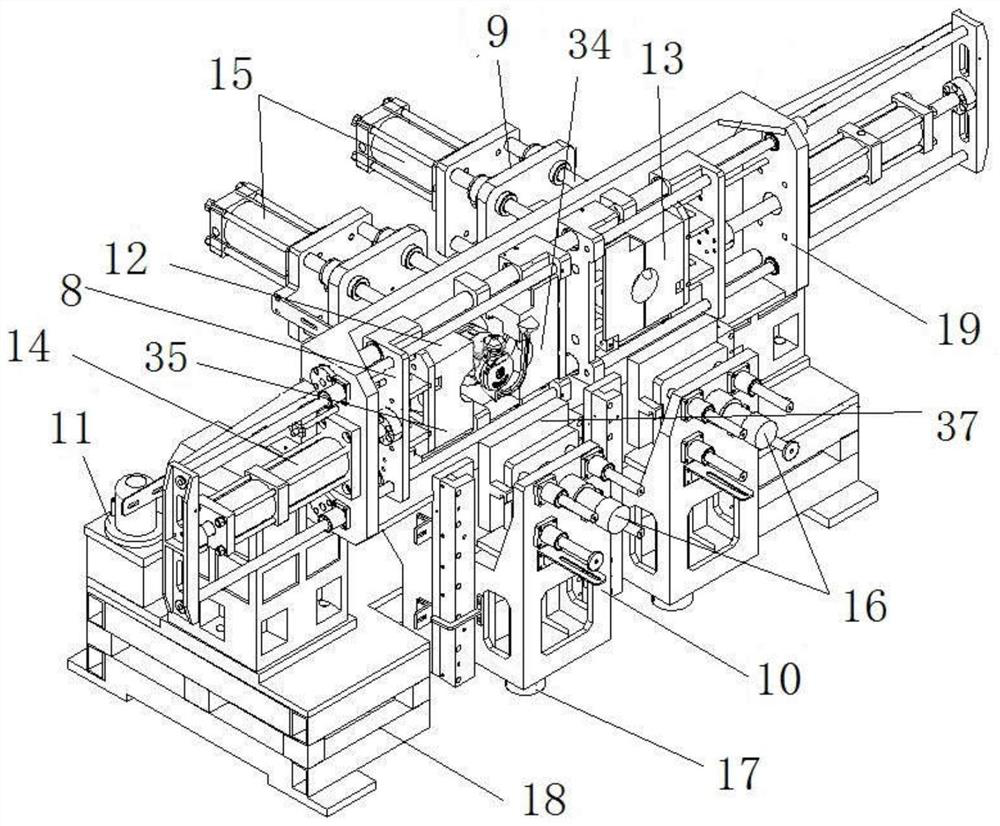

[0042] T...

Embodiment 2

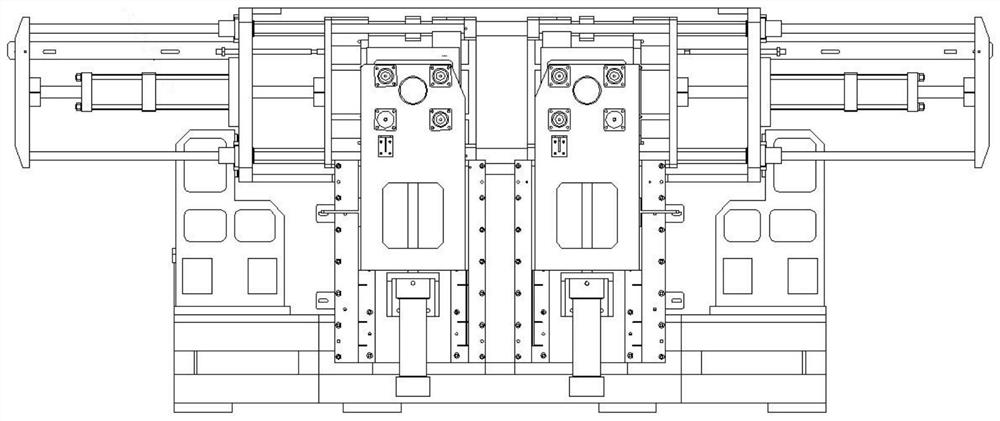

[0048] A double-mold casting machine for pouring aluminum piston blanks with lateral core pulling, the structure is as described in Embodiment 1, the difference is that the left mold 12 includes mold A34, mold B35, mold C36 and mold D34, and mold A34 and mold B are fixed Set on the outer mold base 8, the outer mold base is connected to the external mold telescopic oil cylinder through the cylindrical guide rail, the outer mold base connected to the mold A is fixed on the frame, and the mold C36 is connected to the central core telescopic oil cylinder through the central core mold base and the cylindrical guide rail. Mold D37 is connected to top mold telescopic oil cylinder 16 by cylindrical guide rail, and the pouring cavity shape after mold A34, mold B35, mold C36 and mold D34 are closed is a piston shape, and right mold 13 is identical with left mold 12 structures.

[0049] A gate 38 is set on one side of the mold D37, and the gate 38 is connected to the casting cavity throug...

Embodiment 3

[0055] A double-mode casting machine for pouring aluminum piston blanks by pulling the core horizontally. The structure is as described in Embodiment 1, the difference is that a suction device 11 is arranged on the base 18, and the suction device 11 is connected to the left mold 12 and the right mold respectively. 13. The gas generated by the heating of the salt core is absorbed by the suction device to reduce the porosity of the piston blank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com